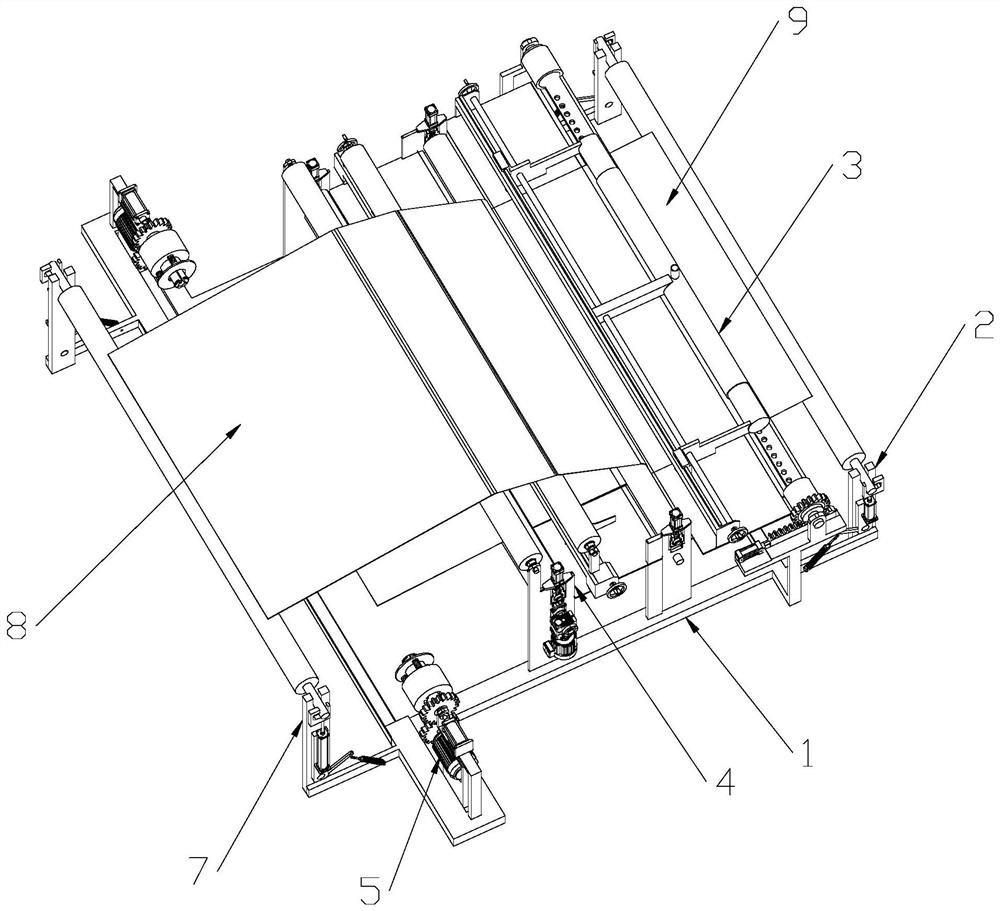

A coating material coating device and coating method for the production of laminating non-woven fabrics

A technology of coating non-woven fabrics and coating devices, which is applied in the field of composite material processing, can solve the problems of high labor intensity and poor flexibility, and achieve the effect of reducing workload, reducing the difficulty of feeding materials, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The coating method of the coating material coating device comprises the following steps:

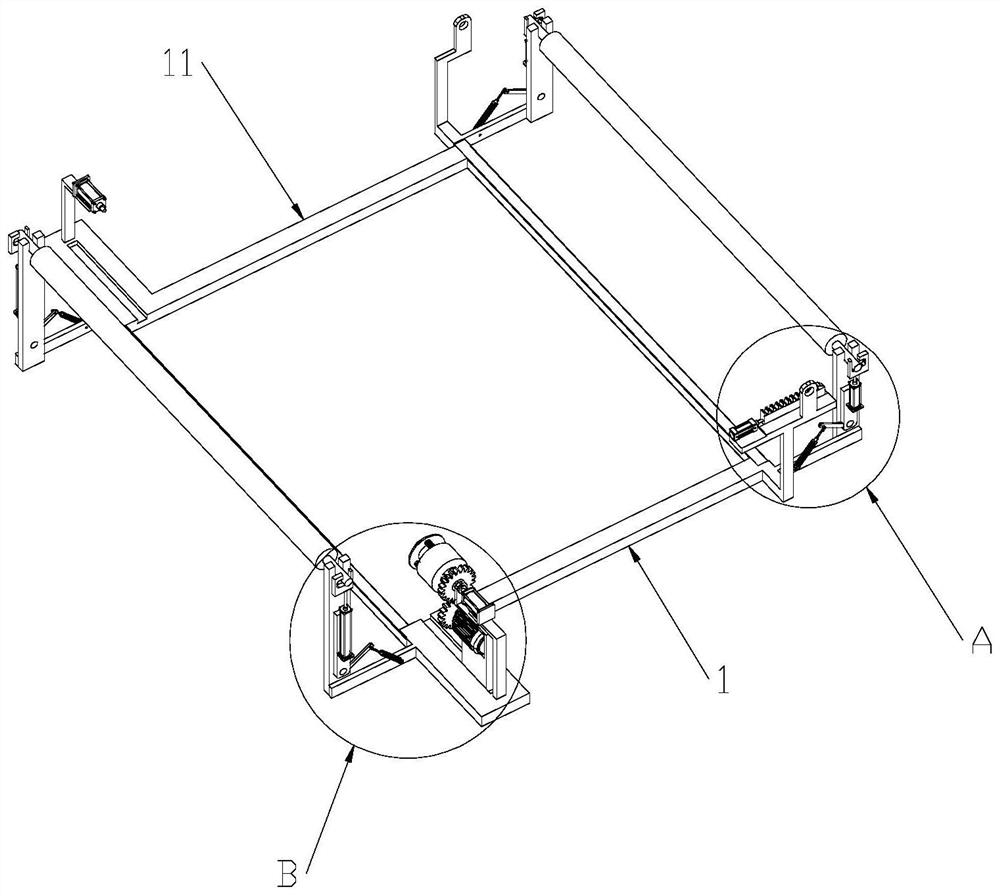

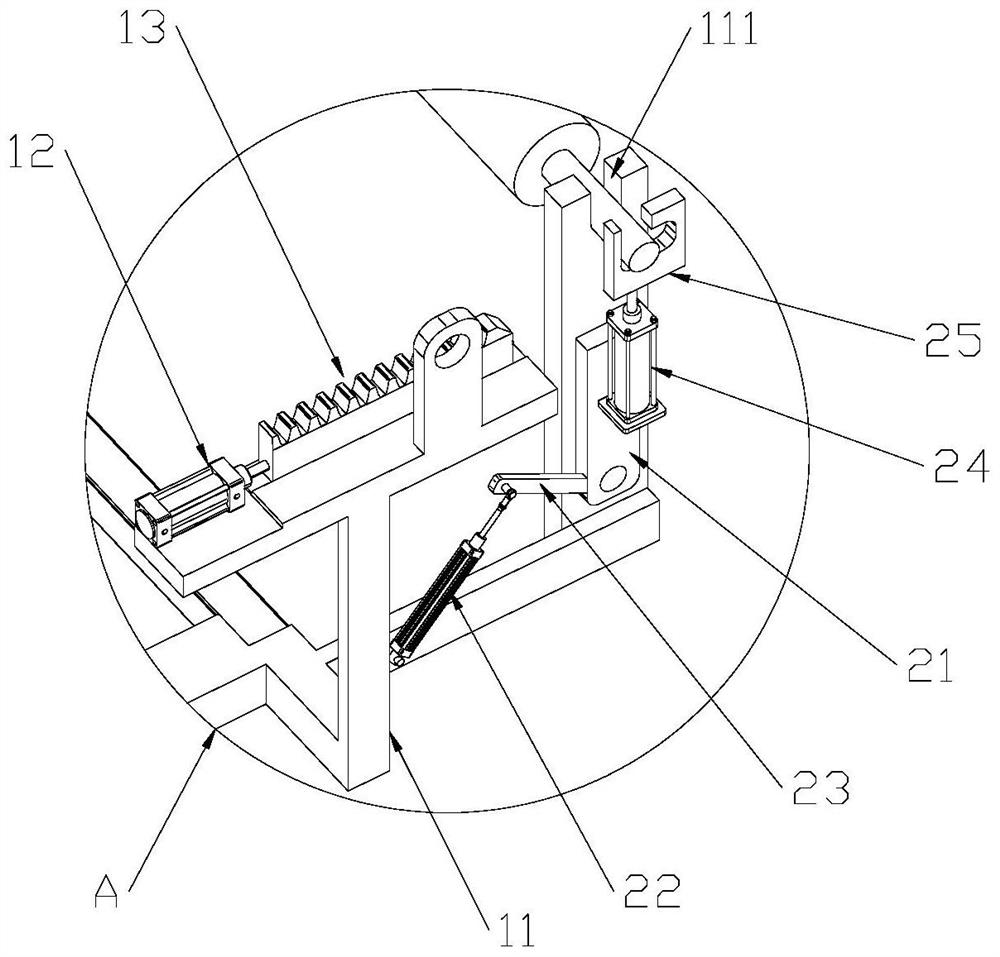

[0057] The output shaft of the third hydraulic cylinder 24 is elongated to push up the support block 25, and the output shaft of the telescopic cylinder 22 pushes the rotating plate 21 to rotate, thereby driving the support block 25 to rotate, placing the non-woven roll material and the film-coated roll material on the first In the limiting groove 26 of a rotating member 2 and a second rotating member 7;

[0058] The telescopic cylinder 22 actively drives the rotating plate 21 to rotate to a vertical state, the feed roller slides to the lower side of the limit groove 26 during the rotation process, the third hydraulic cylinder 24 moves down, the feed roller falls on the groove 111, and the extension of the telescopic cylinder 22 The output shaft continues to return, so that the rotating plate 21 continues to rotate, and the output shaft of the third hydraulic cylinder 24 moves in ...

Embodiment 2

[0062] The present invention can also carry out coating-type coating, and the feeding method is the same as that of Embodiment 1. The difference is that, instead of coating, the coating material 3 is used to coat the film material on the non-woven fabric, and the third driven roller 412 is used to coat the film material. It is uniformly coated with the power roller 15 to complete the non-woven surface coating film material to form a film layer.

[0063] The coating device of the invention can efficiently press the film and the non-woven fabric to form the non-woven fabric. The process of feeding the material to the limit does not require manual intervention, reducing the workload of the staff. The invention can adjust the feeding range of the auxiliary material according to the width of the non-woven fabric, avoid the auxiliary material droplets to the outside of the non-woven fabric, and can actively control the auxiliary material. The feeding process is simple and flexible, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com