Thermal management system for new energy vehicle and new energy vehicle

A thermal management system and technology for new energy vehicles, applied in the field of new energy vehicles, can solve the problems of complex structure, waste of energy, insufficient utilization of waste heat, etc., and achieve the effects of simple pipeline arrangement, simple system and healthy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

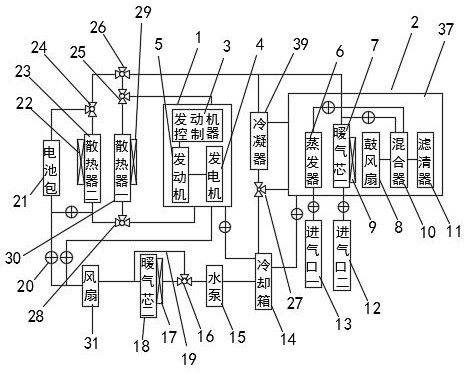

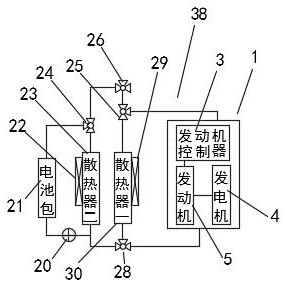

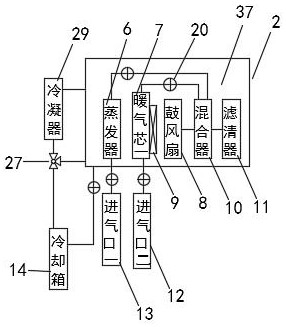

[0030] Refer to the attached Figure 1-5 , a thermal management system for a new energy vehicle of this embodiment and a new energy vehicle, including a heat source assembly 1, an assembly 37, an assembly heat dissipation system 2, a first heat collection system 38, a battery pack heat dissipation system 34 and an engine Heat dissipation system 35, the assembly heat dissipation system 2 includes evaporator 6, heating core one 7, blower fan 8, mixer 10, filter 11, cooling box 14, condenser 39, three-way valve one 27 and solenoid valve 20, the evaporator 6 and the heating core one 7 are connected to the mixer 10, the heating core one 7 is connected to the heater one 9, the mixer 10 is connected to the blowing fan 8 and the filter 11, and the cooling The tank 14 communicates with the condenser 39 and the assembly 37 through the three-way valve one 27, and the first heat collection system 38 includes the engine controller 3, the engine 5, the generator 4, the radiator one 30, and ...

Embodiment 2

[0040] Refer to the attached Figure 6-7 , and the difference from Embodiment 1 is that: the first heat collection system 38, radiator three 32 and heater five 33 form a second heat collection system 36, the radiator three 32 communicates with heater five 33, and the heat dissipation The third device 32 is connected to the battery pack 21.

[0041] The specific implementation scenarios are:

[0042] When those skilled in the art use the present invention, when the heat source assembly 1 composed of the engine controller 3, the generator 4 and the engine 5 is radiated and cooled, the coolant in the cooling box 14 flows through the heat source assembly 1 to cool the heat source assembly 1, The coolant flows through the three-way valve three 25, the three-way valve four 26 and the condenser 39, and finally returns to the cooling box 14; when cooling the battery pack 21, the coolant in the cooling box 14 flows through the water pump 15, the three-way Valve six 16, bypass pipe 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com