Waste resin regeneration treatment method

A treatment method and waste resin technology, applied in recycling technology, plastic recycling, etc., can solve the problems of waste resin not being processed in time, high processing and transportation costs, accumulation of APG waste resin, etc., and achieve resource recycling Utilization, stress relief, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

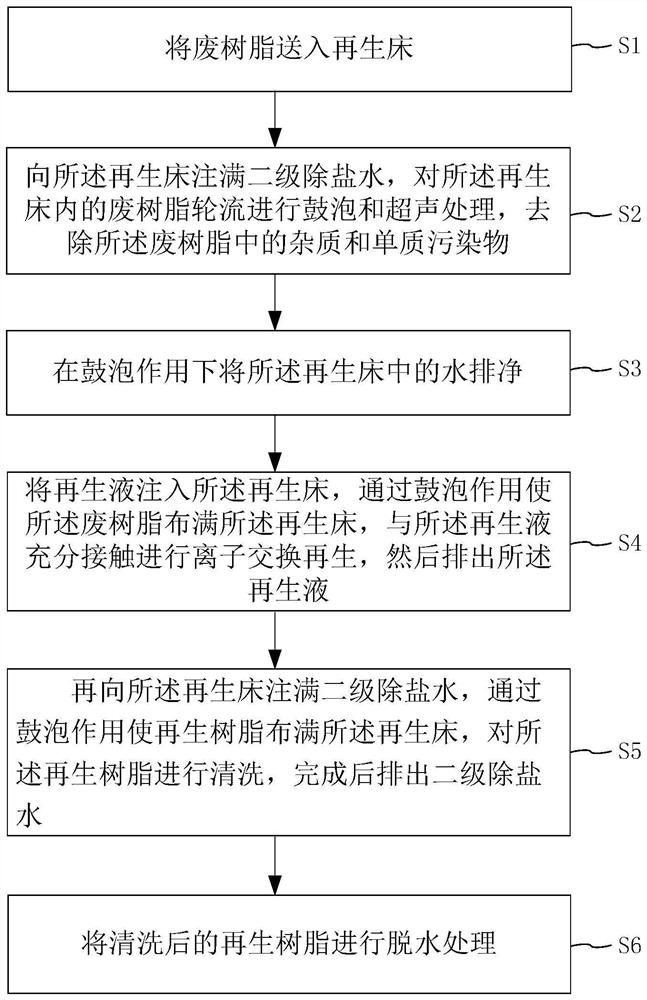

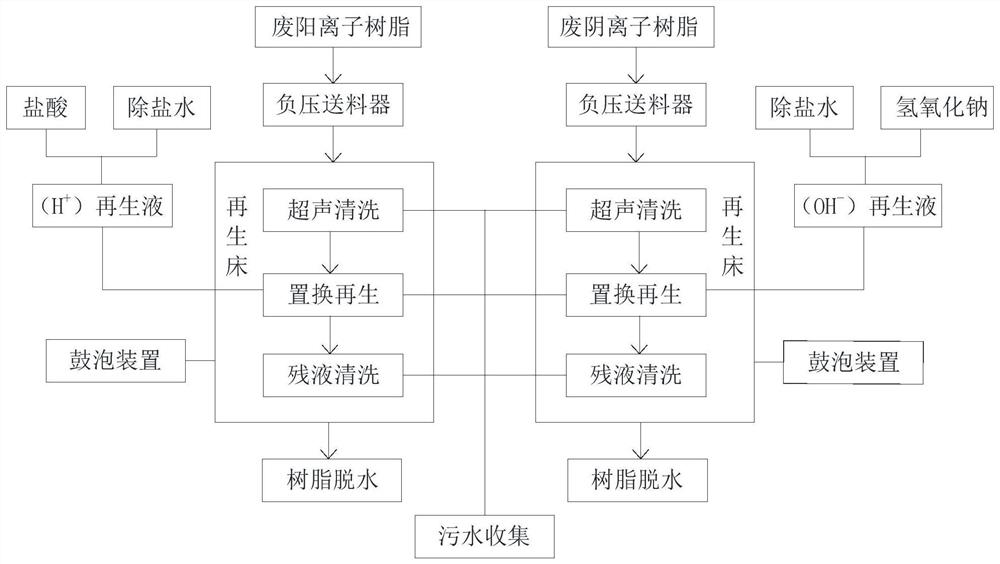

[0033] combine figure 1 , figure 2 , waste resin regeneration treatment method of the present invention is applicable to the regeneration treatment of nuclear power plant APG system waste resin, and this regeneration treatment method comprises the following steps:

[0034] S1. Feeding: send the waste resin into the regeneration bed.

[0035] For the feeding of waste resin, it is preferable to use a negative pressure feeder, which realizes feeding by sending compressed air to the feeding pipe to form a negative pressure. The feeding efficiency is high, and the waste resin can be prevented from being broken during the feeding process.

[0036] Resins usually have cationic resins and anionic resins, so waste resins are also divided into waste cationic resins and waste anion resins. Depending on the type of resin, the regeneration bed corresponds to either a cationic regeneration bed or an anion regeneration bed.

[0037] Due to the difference in resin expansion rate, the effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com