Pumping well polish rod sealing assembly

A technology for pumping wells and polished rods, applied in sealing/packing, drilling pipes, drilling equipment, etc., can solve the problems of shortened service life, time-consuming and laborious replacement, and affect the normal production of oil wells, so as to reduce wear and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

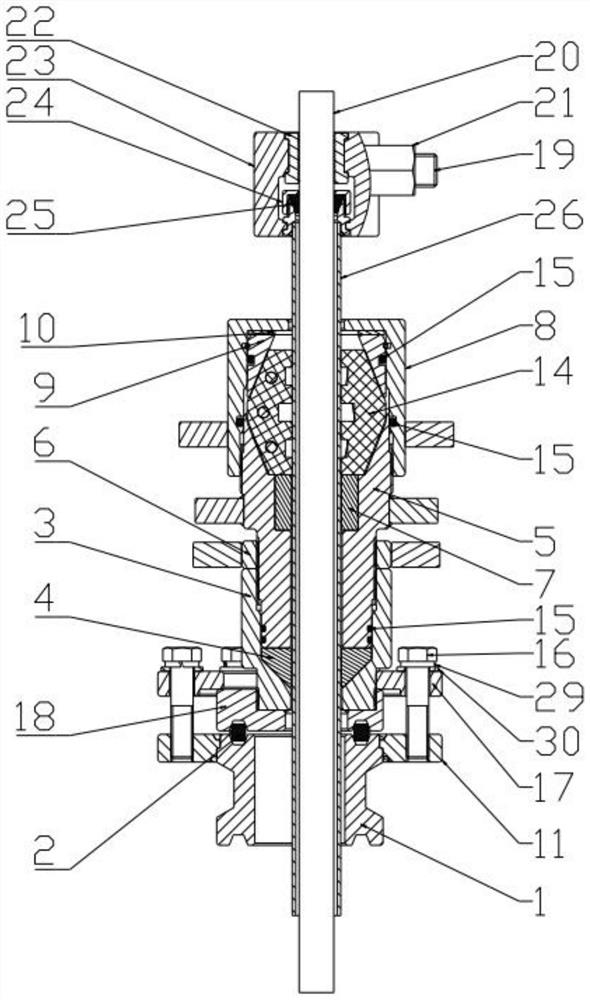

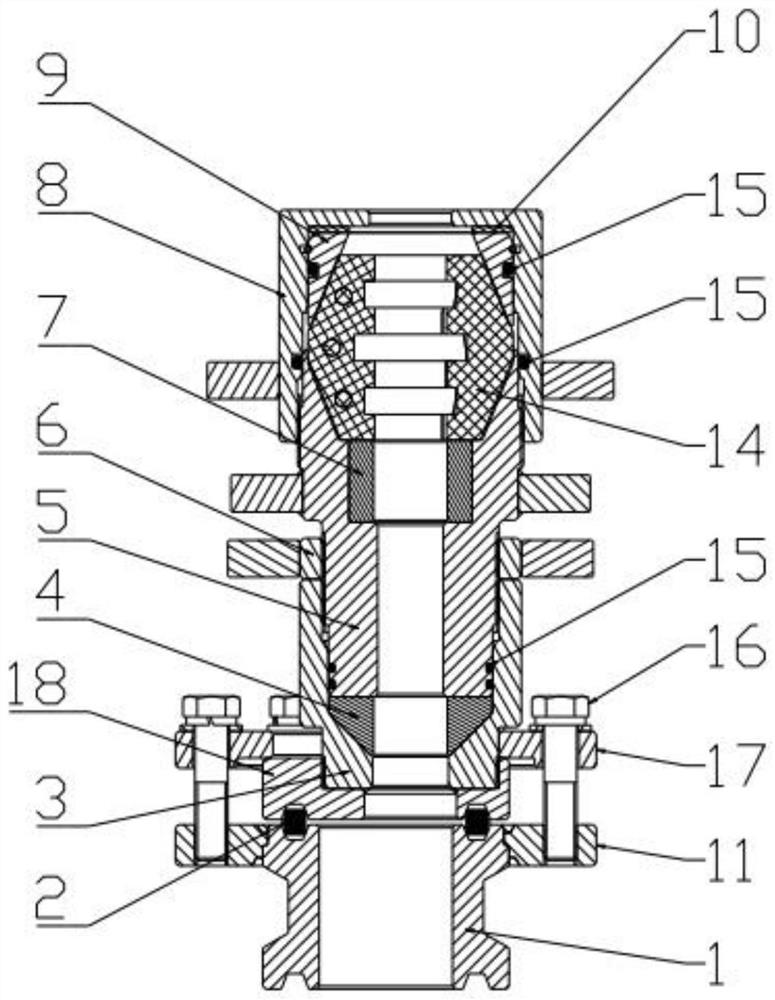

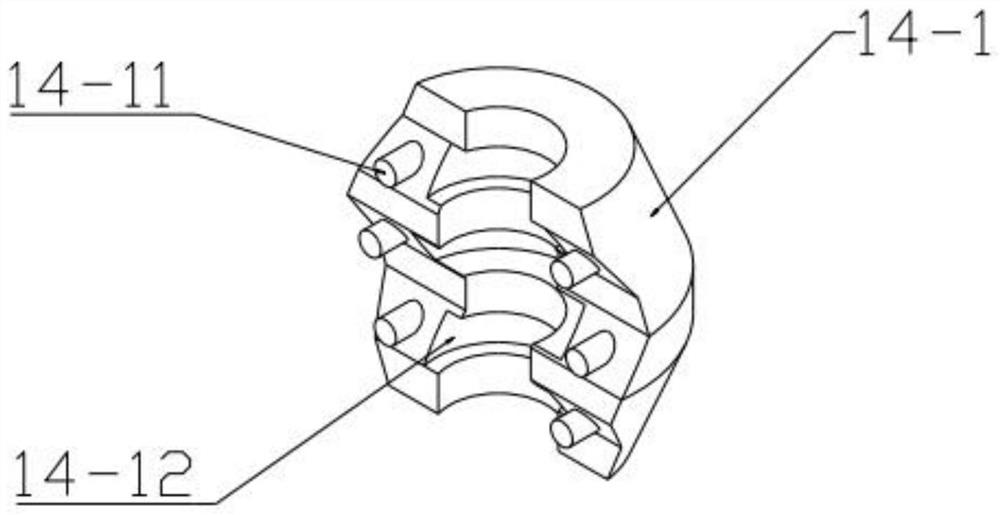

[0041] Specific implementation plan one: combine Figure 1 to Figure 4 As shown, the present invention provides a polished rod sealing assembly for pumping wells, which is characterized in that it includes:

[0042] The eccentric flange 1, the lower end of the eccentric flange 1 is used to connect with the oil pumping wellhead, the eccentric flange 1 is sleeved on the polished rod 20, and the eccentric flange 1 and the polished rod 20 are not coaxially arranged ;

[0043] The main body 3 of the deviation adjustment cavity is sleeved on the polished rod 20, and the eccentric flange 1 and the main body 3 of the deviation adjustment cavity are connected through the lower body 18 of the deviation adjustment cavity and the upper body 17 of the deviation adjustment cavity;

[0044] The seal 4 of the sealer sleeved on the polished rod 20, the seal 4 of the sealer is located in the main body 3 of the deviation adjustment cavity;

[0045] The stuffing chamber 5 sleeved on the polishe...

specific Embodiment approach 2

[0051] Specific implementation plan two: combine figure 1 As shown, it also includes a casing 26, the casing 26 is sleeved on the polished rod 20, the eccentric flange 1, the main body 3 of the deviation adjustment cavity, the lower body 18 of the deviation adjustment cavity, the upper body 17 of the deviation adjustment cavity, the well sealing The device seal 4, the stuffing cavity 5, the centralizing sleeve 7, the split-type conical seal 14 and the split-type conical sealing cap 8 are sequentially socketed on the casing 26. The casing 26 is used to protect the polished rod 20. The outer surface has a high degree of smoothness, high hardness, strong corrosion resistance, and small frictional resistance, which can increase production, save money, and have environmental protection effects. It can prolong the service life of the polished rod 20 and avoid frequent replacement of seals. Assembly, effectively reducing the labor intensity of the staff. The other combinations and c...

specific Embodiment approach 3

[0052] Specific implementation plan three: combination figure 1 As shown, the outer wall of the casing 26 is provided with an industrial hard chrome layer with a thickness of 0.03-0.08 mm, which can resist corrosion and reduce frictional resistance, and can effectively protect the polished rod 20 . The other combinations and connections of this embodiment are the same as those of the second embodiment.

[0053] Specific implementation plan four: combination figure 1 As shown, the gap between the polished rod 20 and the sleeve 26 is 1-3 mm, and the wall thickness of the sleeve 26 is 2-3 mm. The gap between the polished rod 20 and the sleeve 26 and the sleeve can be adjusted according to actual application conditions. The thickness of the pipe wall of the pipe 26 can adjust the length and diameter of the sleeve pipe 26 according to the stroke length of the pumping well and the diameter of the polished rod 20 . The other combinations and connections of this embodiment are the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com