Semiconductor material heat treatment device for mobile terminal

A heat treatment device and mobile terminal technology, which is applied in semiconductor/solid-state device manufacturing, lighting and heating equipment, furnaces, etc., can solve problems such as inconvenience, danger, and air replacement leakage in the unloading process, and achieve convenient control and adjustment, and convenient sintering Process, increase the effect of heating purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

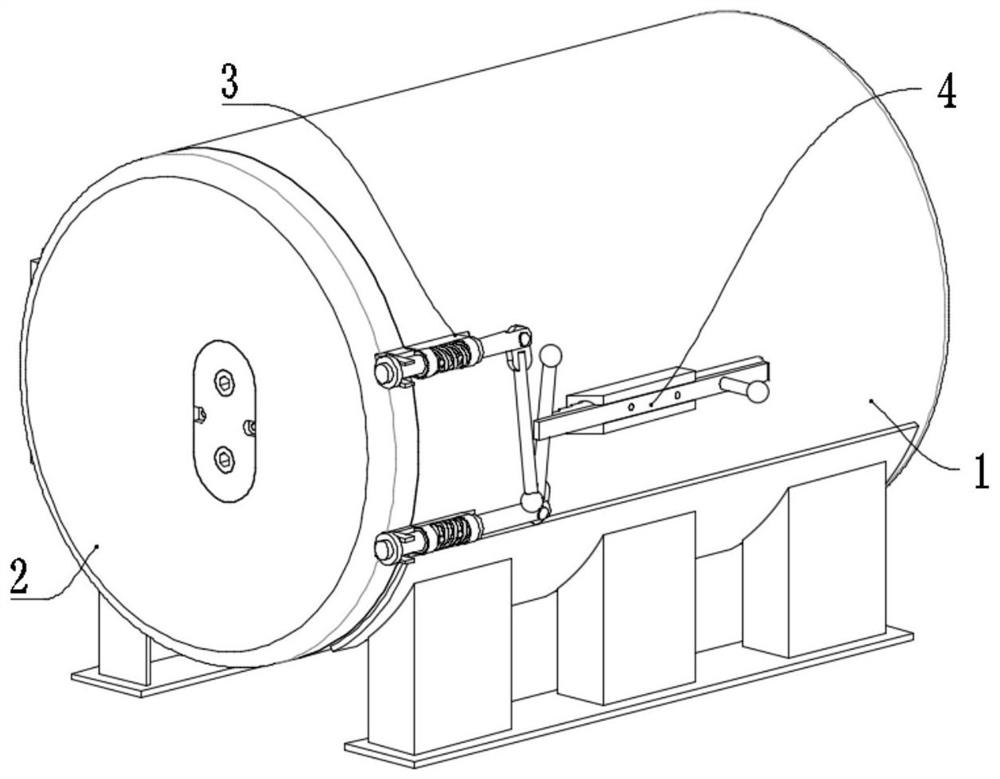

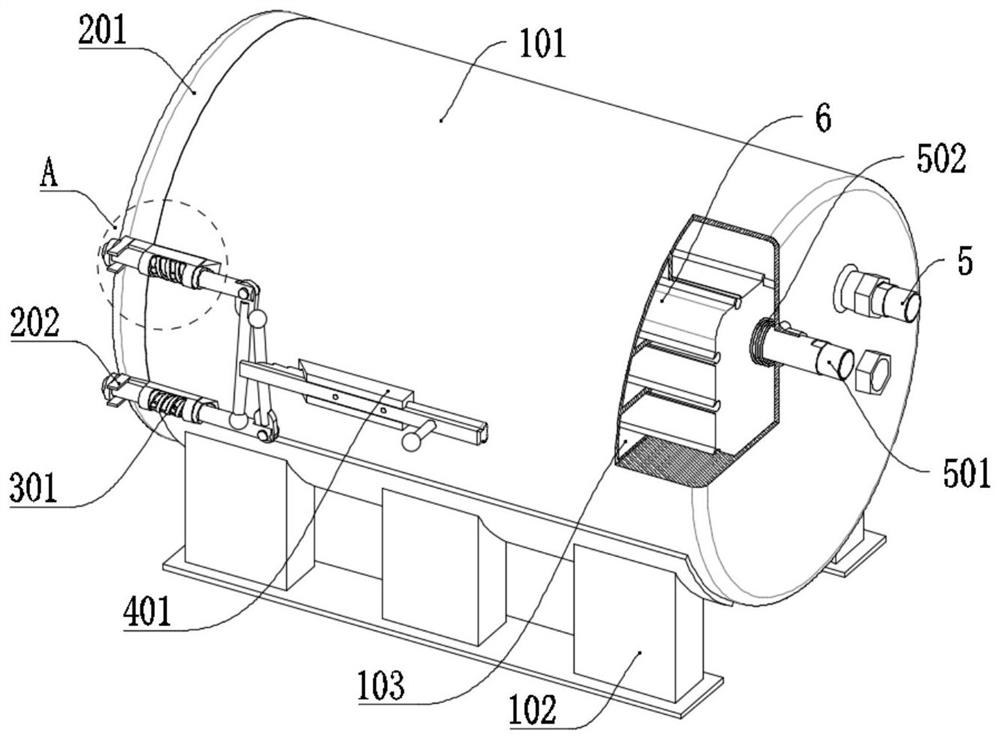

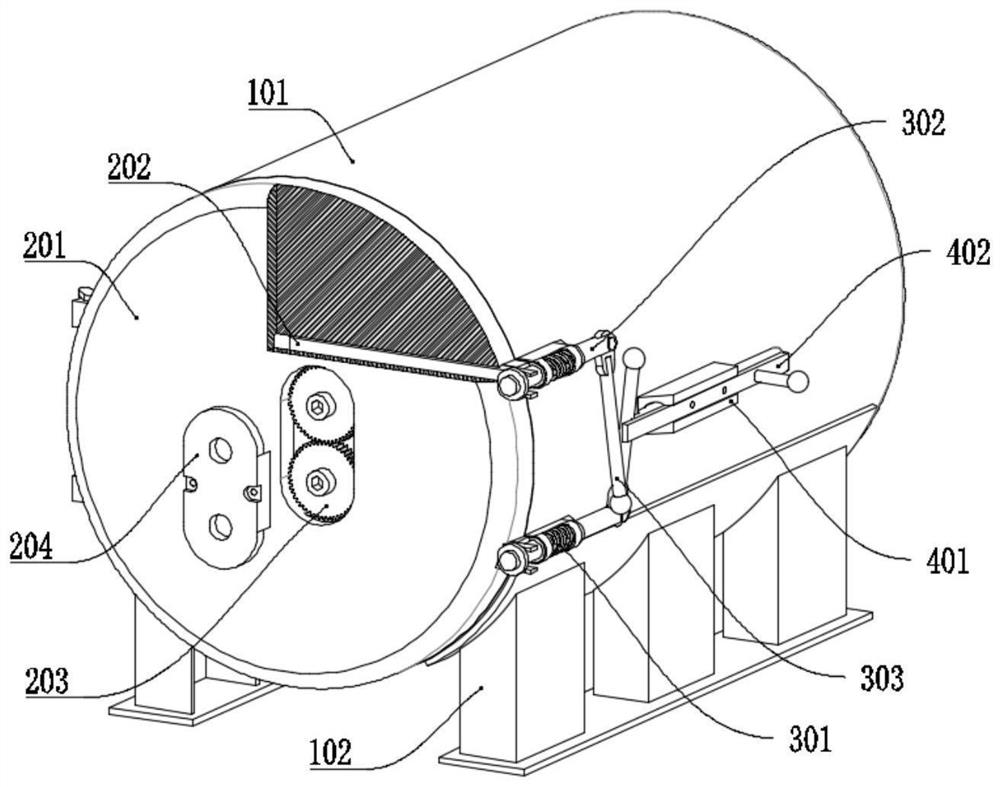

[0061] as attached figure 1 to attach Figure 9 Shown:

[0062] The present invention provides a semiconductor material heat treatment device for mobile terminals, including a tank device 1;

[0063] The sealing structure 2, the sealing structure 2 is a vertical plate structure, the sealing structure 2 is hingedly installed at the front end of the tank device 1, the tank device 1 includes: the installation tank 101, the installation tank 101 is a barrel-shaped structure, and the inner wall is fixed with a spacer Plates 103 and spacer plates 103 are arranged in a circular array, and the spacer plates 103 form the grooves with a square structure on the inner wall. Through the square grooves formed by the spacer plates 103, the effect that the inner box structure 6 is convenient to install is realized. Each group of spacers The ends of the plates 103 are all equipped with heating structures. By setting the ends of the spacer plates 103 as heating structures, the heating purpose...

no. 2 example

[0088] Lifting device 8, the lifting device 8 is a sliding structure, and the lifting device 8 carries the bearing device 7.

[0089] Wherein, lifting device 8 includes:

[0090] Mounting plate 801, the mounting plate 801 is a rectangular plate structure, wheels are installed on the mounting plate 801, through the grooves with wheels, the lifting device 8 is easy to move, the middle of the mounting plate 801 is provided with a mounting groove;

[0091] The support frame 802, the support frame 802 is a C-shaped frame structure, the support frame 802 is provided with two types of six groups in total, the first three groups of support frames 802 are hingedly installed on the mounting plate 801;

[0092] The carrier 803, the carrier 803 is a frame structure, the ends of the first type of support 802 are connected to the carrier 803, and the bottom of the carrier 803 is hingedly installed with the second type of support 802;

[0093] Bottom slide 806, bottom slide 806 is a long pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com