Flue gas desulfurization oxidation system fault prediction method based on machine learning algorithm

A machine learning, oxidation system technology, applied in the field of industrial flue gas treatment, can solve the problems of increasing the oxidation air flow, increasing the risk of failure, adverse absorption, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

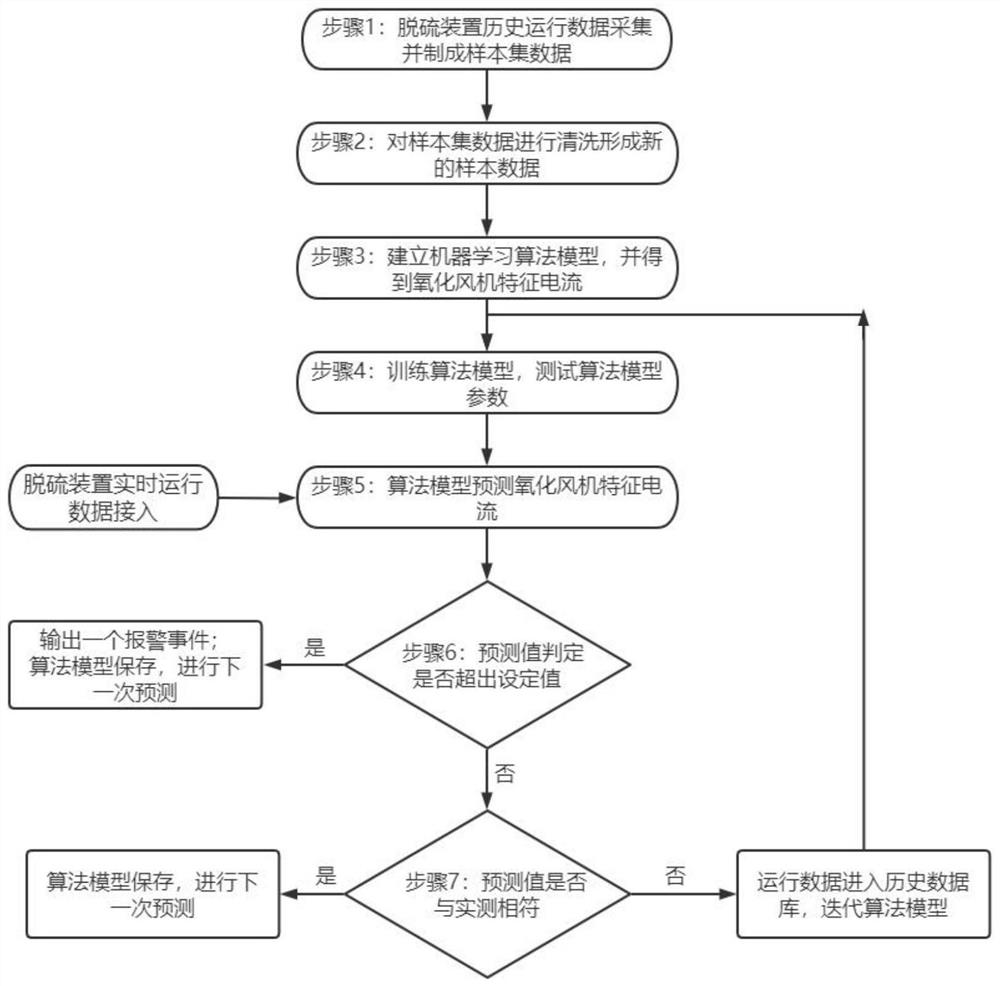

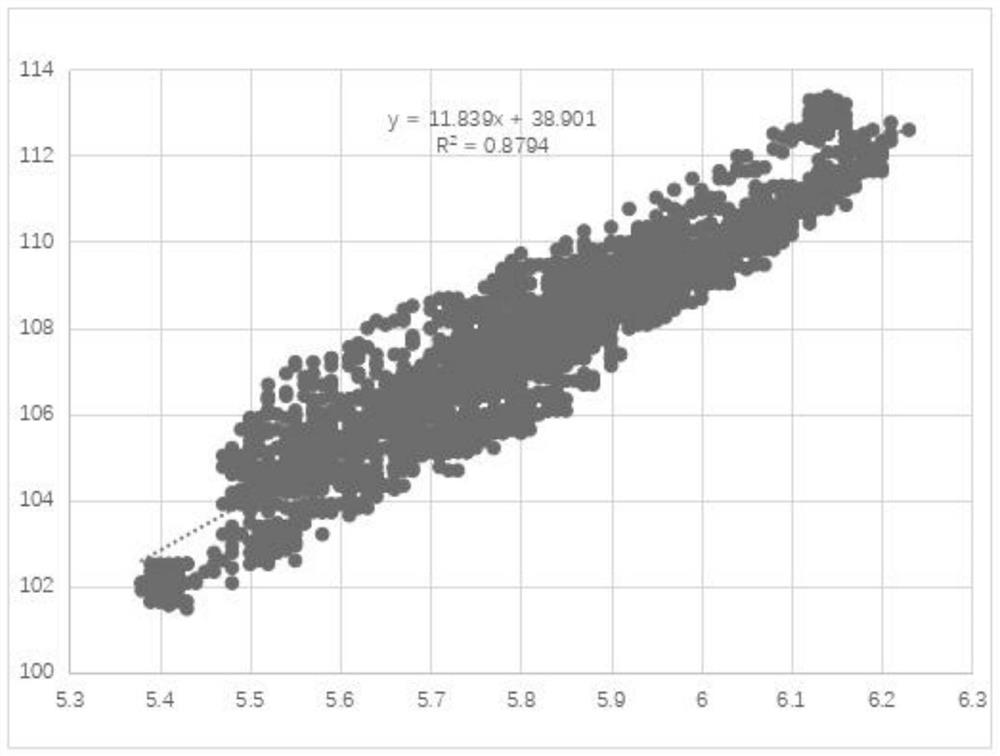

[0044] Please refer to figure 1 figure 2 image 3 as well as Figure 4 , the present invention provides a method for predicting a failure of a flue gas desulfurization oxidation system based on a machine learning algorithm, which is characterized in that it includes the following steps:

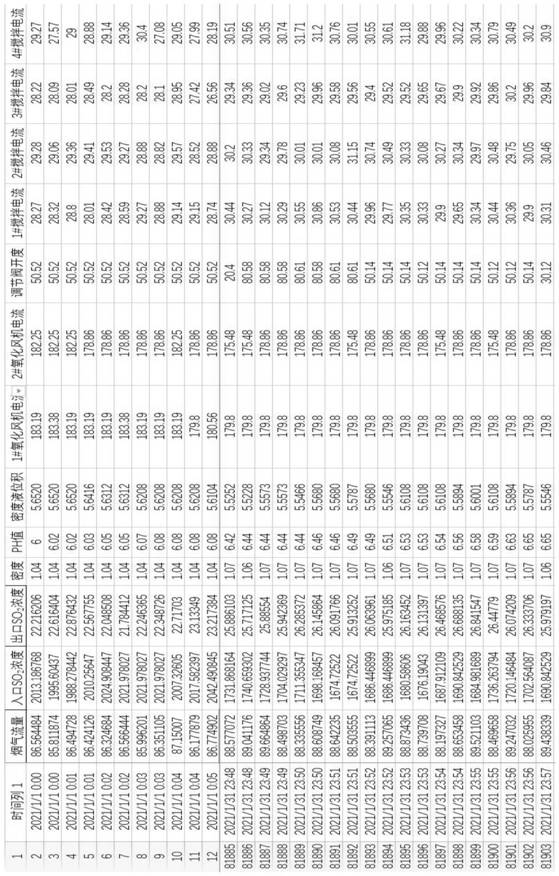

[0045] S1: Collect the historical operation data of the flue gas desulfurization device as the sample set data;

[0046] S2: Organize the sample set data collected in S1 into the type and format required by machine learning, and form the sample data of machine learning through data cleaning;

[0047] S2-1: Delete the missing values in the sample set, and sort from small to large to get the sequence of each parameter {X 1 ,X 2 ,X 3 ,……X n};

[0048] S2-2: Order Q L =X (n / 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com