3D printing quartz sand waste sand recovery treatment device

A recycling and 3D printing technology, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc. The effect of ejection pressure to improve pickling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

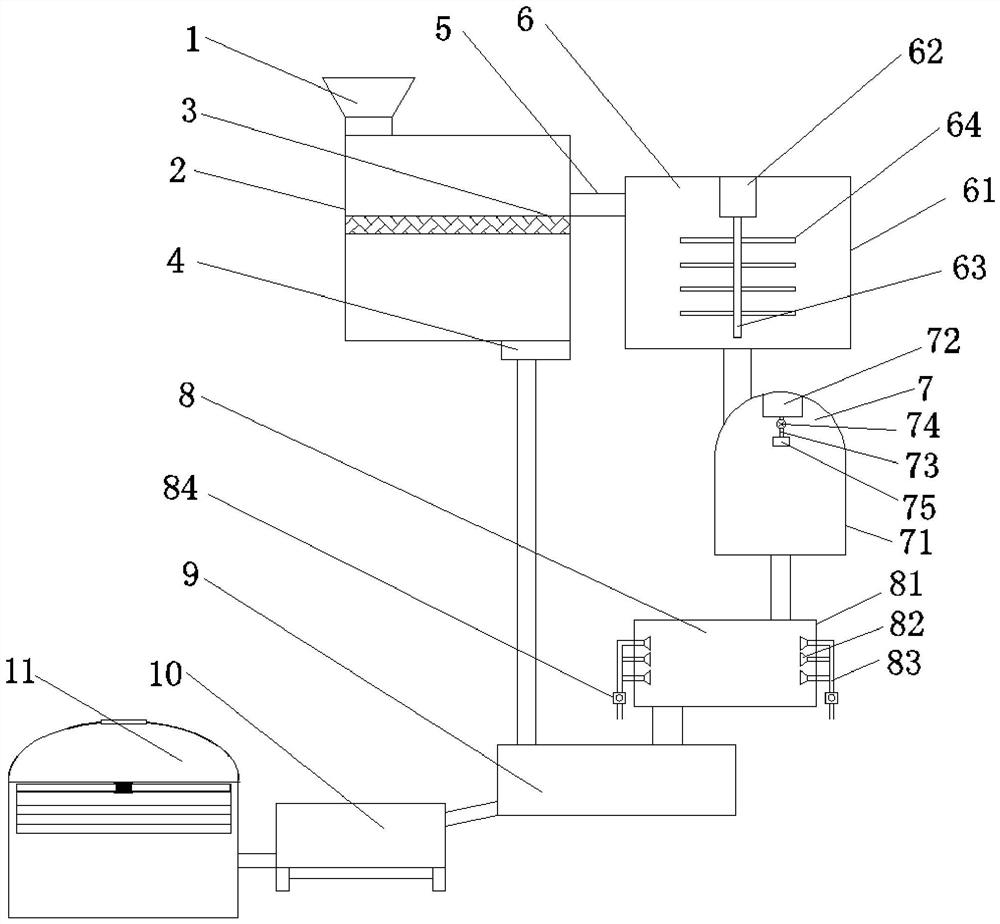

[0046] A 3D printing quartz sand waste sand recovery treatment device, comprising a feed hopper, the feed hopper is connected with a screening cylinder, the screening cylinder is provided with a sieve plate, and the bottom of the screening cylinder is connected with a first outlet A material trough, the side wall of the screening cylinder is located above the sieve plate and communicated with a second discharge trough, the second discharge trough is connected with a crushing mixer, and the discharge port of the crushing mixer is connected with a dissolving tank, and the dissolving The outlet of the tank is connected with a pickling box, the outlet of the pickling box is connected with a cleaning box, the first outlet is connected with the cleaning box, and the outlet of the cleaning box is connected with the ultrasonic cleaning machine. The feed port is connected, and the discharge port of the ultrasonic cleaning machine is connected with a dryer.

[0047] With this setting, t...

Embodiment 2

[0049] On the basis of Embodiment 1, the crushing mixer includes a housing, a driving motor is installed on the top wall of the housing, an output end of the driving motor is connected to a stirring shaft, and crushing blades are connected to the stirring shaft. Through this setting, the drive motor drives the stirring shaft to rotate, and the crushing blades on the stirring shaft follow the rotation to crush and disperse the sand blocks and sand grains in the waste sand.

Embodiment 3

[0051] On the basis of the above embodiments, there are multiple crushing blades, and the crushing blades are evenly distributed along the length direction of the stirring shaft. Through this setting, the contact surface between the crushing blade and the sand blocks and sand grains in the waste sand can be enlarged, and the efficiency of crushing and dispersing can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com