A grinding device for processing low hydroxyl quartz glass

A quartz glass and grinding device technology, applied in grinding devices, grinding/polishing safety devices, grinding machine tools, etc., can solve the problems of limiting grinding processing efficiency, lack of practicability, time-consuming and laborious, etc., to ensure physical health and speed up The effect of work efficiency and convenient centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

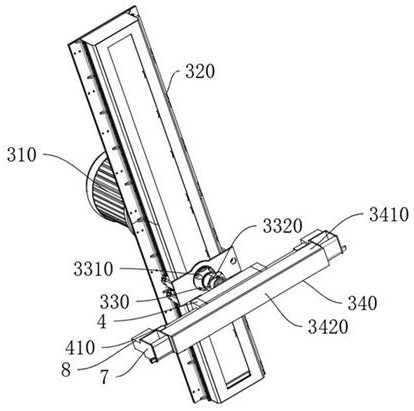

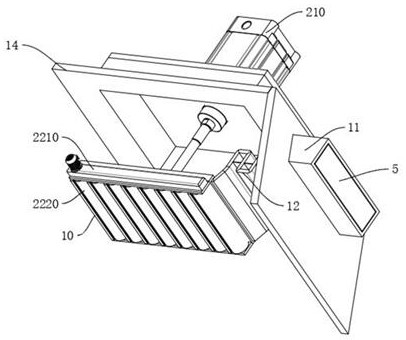

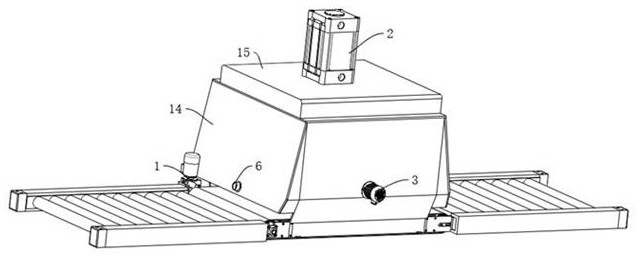

[0044] refer to Figure 1 to Figure 6 , in the present embodiment, a grinding device for low-hydroxyl quartz glass processing is proposed, which includes a conveyor belt base 1 and a grinding box 14 arranged on the conveyor belt base 1. The conveyor belt base 1 opens from the lower end of the grinding box 14 Passing through, the top of the grinding box 14 is provided with a grinding mechanism 2 that can be vertically lifted, and the top of the grinding box 14 is provided with a housing housing 15 for accommodating the grinding mechanism 2;

[0045] The grinding mechanism 2 has three position states, one is that the grinding mechanism 2 descends and contacts the surface processing position of the quartz glass surface on the conveyor base 1, and the other is that the grinding mechanism 2 descends and contacts the quartz glass on the conveyor base 1 The wide side processing position state of the side of the glass surface, the third is that the grinding mechanism 2 ascends into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com