Energy-saving production process of concrete duct piece

A production process and concrete technology, which is applied in the energy-saving production process of concrete segments, can solve the problems of immature production level of concrete segments in horseshoe-shaped tunnels, and achieve the effects of saving production resources, improving impermeability, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

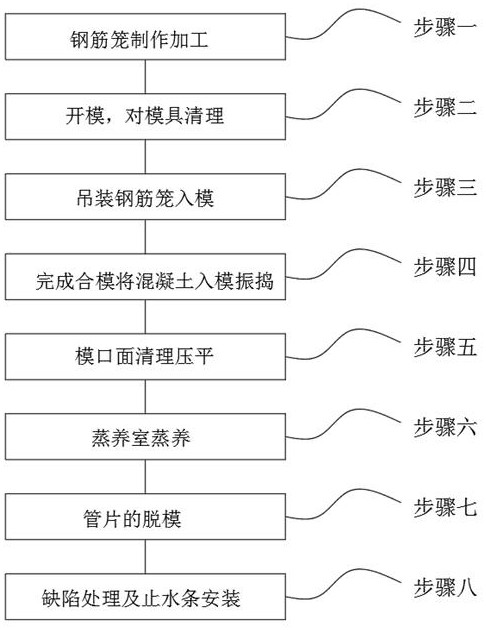

[0029] The energy-saving production process of concrete segments includes step 1, making and processing steel cages; step 2, opening the mold, cleaning the mold, and spraying release agent; step 3, hoisting the steel cage into the mold; step 4: completing the mold closing and putting the concrete into the mold Vibration; Step 5: Cleaning and flattening the die surface; Step 6: Steam curing in the steam curing room; Step 7: Demolding of the segment; Step 8: Defect treatment and installation of water stop strips;

[0030] Among them, in the above step 1, the staff selects the steel bars for making steel cages and removes the oil stains and hammers the peeling skin before processing. The steel bars after derusting are cut according to the size and marked. The steel bar ingredient list or technical disclosure document is carried out, and it is strictly forbidden to change the production method at will and complete the production of the steel cage;

[0031] In the above step 2, the...

Embodiment 2

[0039] The steel bars in step 1 must be inspected according to the specified frequency before they can be used, and the use of unqualified materials is prohibited; the quality of the joints of the steel bars, the quality of the welding of the steel bars, the frequency inspection is qualified, and the welded joints of the steel bars meet the specifications and design requirements; the spacing of the main bars of the steel cage , Strictly control the spacing of the main ribs, and the spacing deviation is controlled within ±0.5d; the mold material in the second step is selected from high-precision steel molds, so that the mold has small deformation, high precision, and many cycles during use, increasing the service life; In step 3, before the steel bar cage of the crane is put into the mold, the concrete protective layer pad should be installed according to the specified position. The concrete of the pad should have the same label as the concrete of the segment. ), weld the embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com