Laser digital jet printing method

A digital jet printing and laser technology, applied in the directions of copying/marking methods, printing, ink, etc., can solve the problems of large application restrictions, the pattern and text cannot be adjusted, and achieve the effect of super error correction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

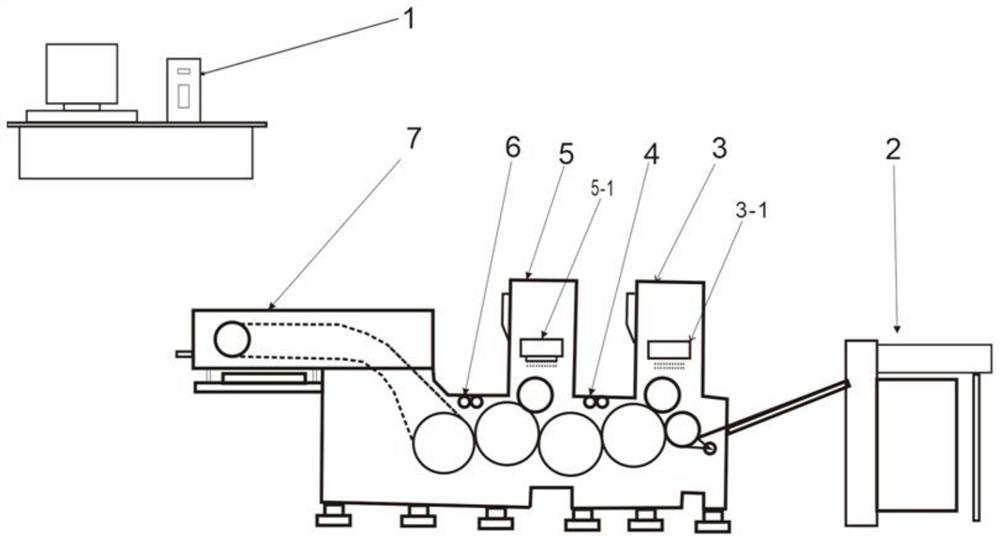

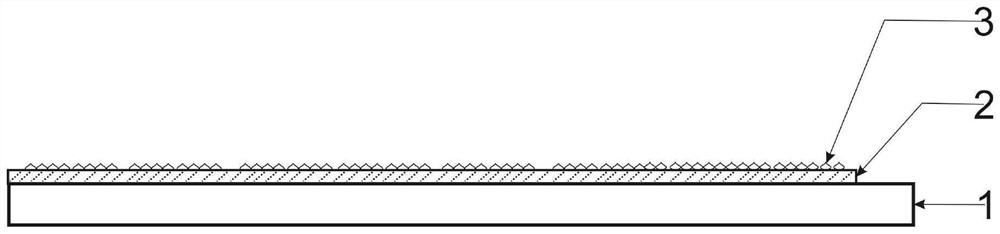

[0026] Embodiment 1: as Figure 1-Figure 2 As shown, a laser digital inkjet printing method, through the online inkjet printing of multiple sets of digital nozzles, firstly through the inkjet printing of the first inkjet printing unit, to achieve graphic inkjet printing with a uniform flat bottom effect. When printing through the digital nozzle of the second printing unit, use the program to control the position of the nozzle, selectively print the position and shape of the graphic, and the value of the program to control the amount of ink droplets to adjust the thickness of the ink layer, ink droplets Due to the dual effects of gravity and surface tension on the surface of the printed matter, it will form pagoda lines with small tops and large bottoms. The second printing unit performs partial UV varnish jet printing on the mirror background color. The ink thickness of the UV varnish layer is 0.2±0.05mm. Viewed from a different angle, the products all have a beautiful laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com