Photolithographic glass and microstructure processing method thereof

A microstructure and photolithography technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

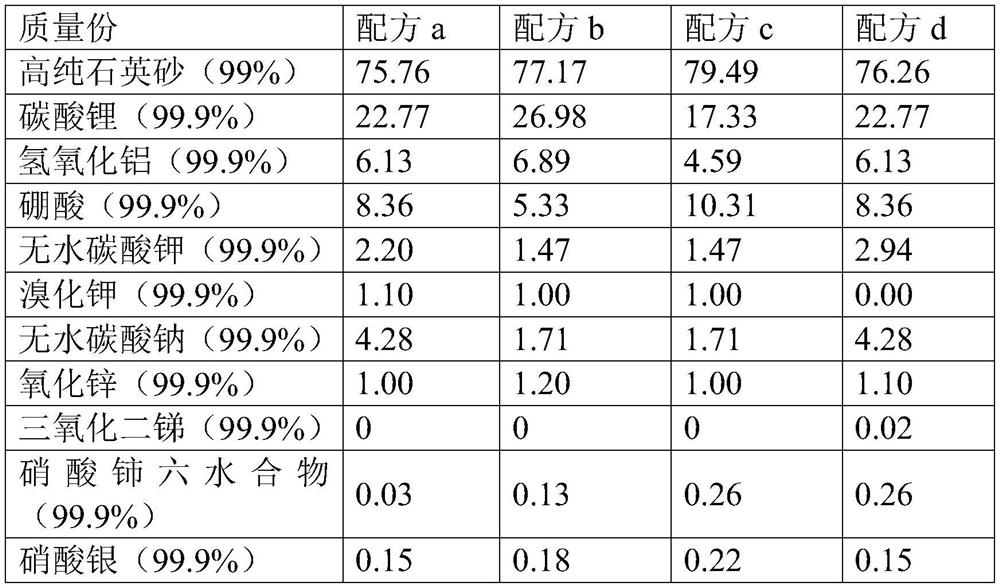

[0056] Examples 1-8 are examples of photolithographic glass of the present invention, wherein Examples 1-4 respectively adopt the glass raw material formulas a-d shown in Table 1, and are prepared by the following preparation method 1, and the prepared glasses have the following properties: Components a-d shown in Table 2; Examples 5-8 were prepared using the glass raw material formulas a-d shown in Table 1, respectively, using the following preparation method 2.

[0057] Table 1 shows the raw material formulations of the photoresistable glasses described in Examples 1-8 of the present invention.

[0058] Table 2 shows the composition of the photoresistable glasses described in Examples 1-4 of the present invention.

[0059] The raw material formula of the photoetching glass of table 1 embodiment 1-8

[0060]

[0061] The composition of the photoetching glass of table 2 embodiment 1-4

[0062] parts by mass Component a Component b component c component d...

Embodiment 9

[0082] This embodiment provides a photolithography method for photolithographic glass wafers, which can realize high-quality processing of glass surfaces. The steps are as follows:

[0083] (1) The lithographic glass of Example 2 is optically processed to obtain a plurality of glass wafers with diameters of 2, 3, and 4 inches respectively, and the glass wafers of each diameter are respectively processed to have 200 μm, 300 μm, Multiple glass wafers with thickness of 400μm and 500μm;

[0084] (2) Use a quartz reticle with an aperture of 50 μm and a spacing of 100 μm to expose each glass wafer to ultraviolet light at an exposure wavelength of 316 nm and an energy density of 3.5 W / cm 2 , for the glass wafer exposure, the relationship between the exposure time and the thickness of the glass wafer is as follows: a glass wafer with a thickness of 200 μm was exposed for 15 minutes, a glass wafer with a thickness of 300 μm was exposed for 20 minutes, a glass wafer with a thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com