Bulk molding plastic and preparation method thereof

A slug molding compound and molding technology, applied in the field of slug molding compound and its preparation, can solve the problems of inability to meet high temperature resistance, electrical strength and bending resistance, inability to meet high-end customers, and mechanical properties to be improved, etc. Achieve the effect of improving impact resistance, high impact resistance and high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

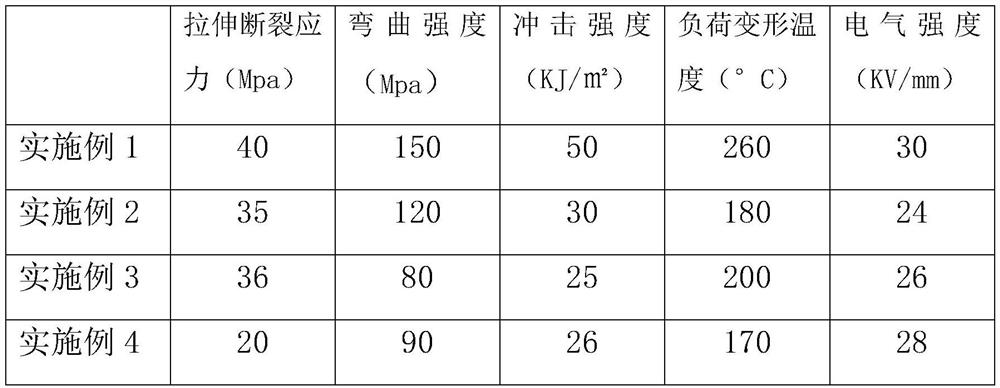

Examples

Embodiment 1

[0019] This embodiment discloses a bulk molding compound. The bulk molding compound consists of raw materials in parts by weight: 30-40 parts of unsaturated resin, 10-20 parts of low shrinkage agent, 10-20 parts of glass fiber, 5-10 parts of initiator, 10-15 parts of thickener, 5-8 parts of aluminum hydroxide, 10-20 parts of calcium carbonate, 1-10 parts of color paste, 8-15 parts of curing agent, 10-20 parts of flame retardant 15-20 parts of heat-resistant agent, 45-60 parts of filler.

[0020] The present invention is further set as follows: the bulk molding compound is composed of raw materials in parts by weight: 35 parts of unsaturated resin, 18 parts of low shrinkage agent, 15 parts of glass fiber, 9 parts of initiator, 12 parts of thickener, hydrogen 6 parts of alumina, 13 parts of calcium carbonate, 4 parts of color paste, 10 parts of curing agent, 15 parts of flame retardant, 18 parts of heat-resistant agent, and 55 parts of filler.

[0021] The further configuration...

Embodiment 2

[0034] This embodiment discloses a bulk molding compound. The bulk molding compound consists of raw materials in parts by weight: 30-40 parts of unsaturated resin, 10-20 parts of low shrinkage agent, 10-20 parts of glass fiber, 5-10 parts of initiator, 10-15 parts of thickener, 5-8 parts of aluminum hydroxide, 10-20 parts of calcium carbonate, 1-10 parts of color paste, 8-15 parts of curing agent, 10-20 parts of flame retardant 15-20 parts of heat-resistant agent, 45-60 parts of filler.

[0035] The present invention is further set as follows: the bulk molding compound is composed of raw materials in parts by weight: 30 parts of unsaturated resin, 15 parts of low shrinkage agent, 12 parts of glass fiber, 8 parts of initiator, 11 parts of thickener, hydrogen 5 parts of alumina, 11 parts of calcium carbonate, 7 parts of color paste, 9 parts of curing agent, 12 parts of flame retardant, 17 parts of heat-resistant agent, and 50 parts of filler.

[0036] The further configuration ...

Embodiment 3

[0049] This embodiment discloses a bulk molding compound. The bulk molding compound consists of raw materials in parts by weight: 30-40 parts of unsaturated resin, 10-20 parts of low shrinkage agent, 10-20 parts of glass fiber, 5-10 parts of initiator, 10-15 parts of thickener, 5-8 parts of aluminum hydroxide, 10-20 parts of calcium carbonate, 1-10 parts of color paste, 8-15 parts of curing agent, 10-20 parts of flame retardant 15-20 parts of heat-resistant agent, 45-60 parts of filler.

[0050] The present invention is further set as follows: the bulk molding compound is composed of raw materials in parts by weight: 38 parts of unsaturated resin, 19 parts of low shrinkage agent, 17 parts of glass fiber, 10 parts of initiator, 13 parts of thickener, hydrogen 7 parts of alumina, 15 parts of calcium carbonate, 5 parts of color paste, 11 parts of curing agent, 16 parts of flame retardant, 16 parts of heat-resistant agent, and 50 parts of filler.

[0051] The further setting of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com