High-strength aluminum-based composite material and preparation method thereof

An aluminum-based composite material, high-strength technology, applied in the direction of nanotechnology, additive manufacturing, and additive processing for materials and surface science, can solve problems such as uneven dispersion, nanoparticle agglomeration, and small particle size, so as to avoid Effect of powder spreading and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

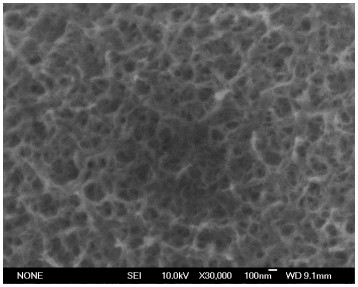

[0025] The AlMgScZr aluminum alloy powder with nano-network microporous structure on the surface was prepared by plasma spheroidization method. The process parameters were: powder feeding rate 10g / min, reactor pressure 6pa, protective gas mixed gas of argon and nitrogen, nitrogen ratio of 0.07 %, the carrier gas flow rate is 5slpm, and the power is 11Kw; the powder is spherical in shape, and the particle size distribution is 1-53 microns. figure 1 and figure 2 It can be seen that the surface of the powder presents a nano-network structure, the surface pore size is 100±20nm, and the pore depth is 80±10nm; this process parameter can prepare high-quality AlMgScZr aluminum alloy powder with a nano-network microporous structure on the surface .

Embodiment 2

[0027] Mix the AlMgScZr aluminum alloy powder with a nano-reticular microporous structure on the surface of Example 1 with the TiN nano-reinforced phase, and the particle size is 20-50nm; specifically, mix the TiN nano-reinforced phase and the aluminum alloy powder according to the mass ratio of 1 : 500ml of absolute ethanol that is placed together with 99, use a stirrer to mix evenly and fully under an argon environment; then dry it in a 45°C oven; phase; use selective laser melting technology to print aluminum alloy powder with TiN nano-enhanced phase on the surface, the process parameters are: laser power 220W, scanning speed 1200mm / s, scanning distance 0.12mm. The prepared high-strength aluminum-based composite material has a tensile strength of 550Mpa.

Embodiment 3

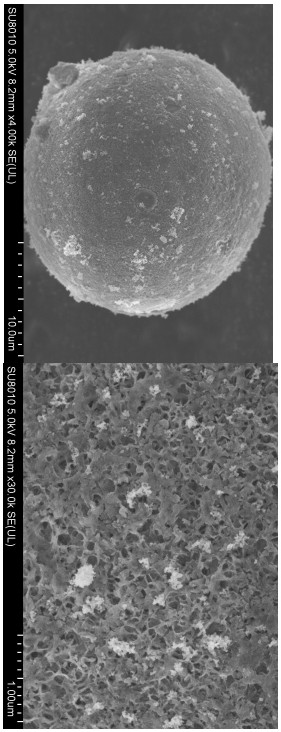

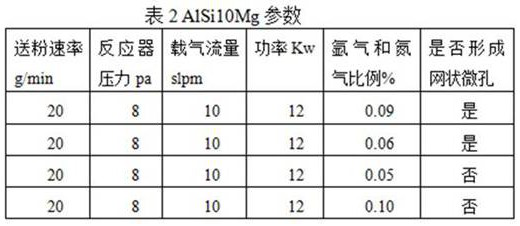

[0029] The plasma spheroidization method is used to prepare AlSi10Mg aluminum alloy powder with nano-network microporous structure on the surface. The process parameters are: powder feeding rate 20g / min, reactor pressure 8pa, protective gas is a mixed gas of argon and nitrogen, and the ratio of nitrogen is 0.09 %, the carrier gas flow rate is 10slpm, and the power is 12Kw; under the process parameters, spherical powder can be prepared with a particle size of 1-53 microns; at the same time, the surface of the powder can also form a nano-network microporous structure with a surface pore size of 200±50 nanometer, and the pore depth is 120±30 nanometers; this process parameter can prepare high-quality AlSi10Mg aluminum alloy powder with a nano-network microporous structure on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com