Assembly type middle plate structure of subway station and construction method of assembly type middle plate structure

A construction method and prefabricated technology, which can be applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of water leakage in the joints of prefabricated mid-plate structures, achieve good bonding, reduce manual operations, The effect of improving the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the description.

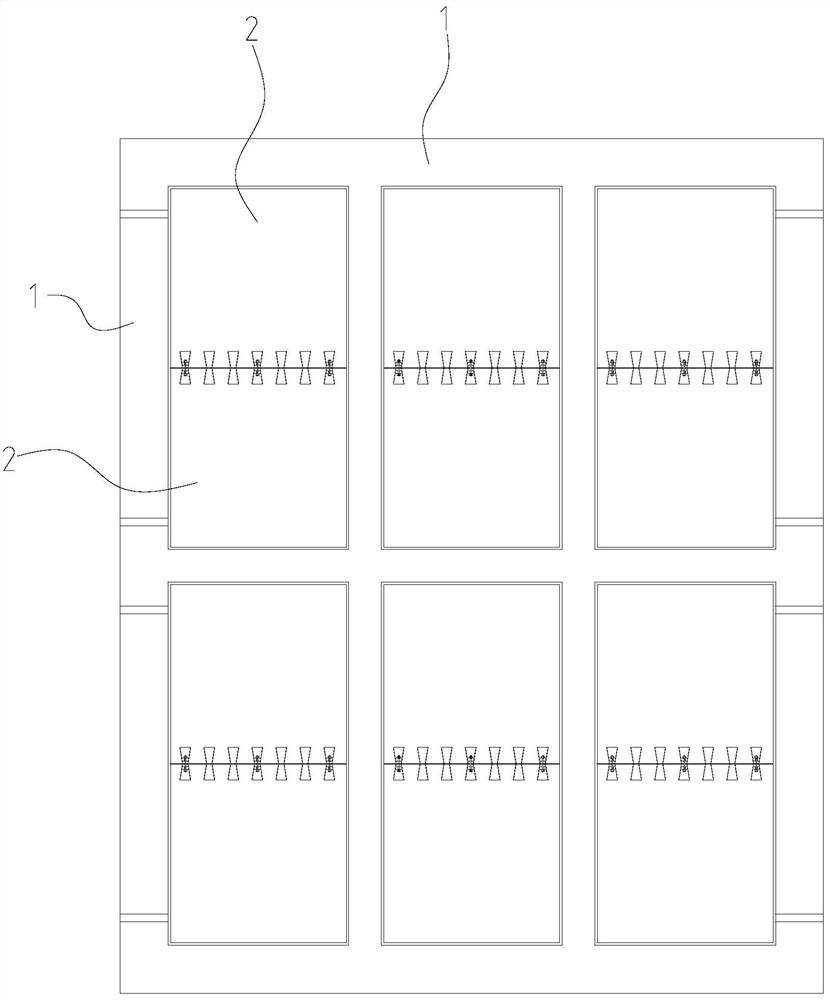

[0031] Such as figure 1 As shown, a prefabricated mid-slab structure of a subway station includes several criss-cross support beams 1 and prefabricated slabs 2. The criss-cross support beams 1 enclose several laying areas, and each laying area is provided with prefabricated slab groups. The prefabricated panel group is composed of one or more than two prefabricated panels 2 connected end to end.

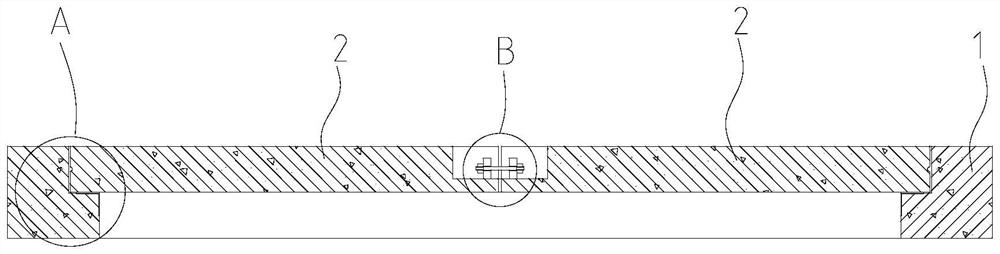

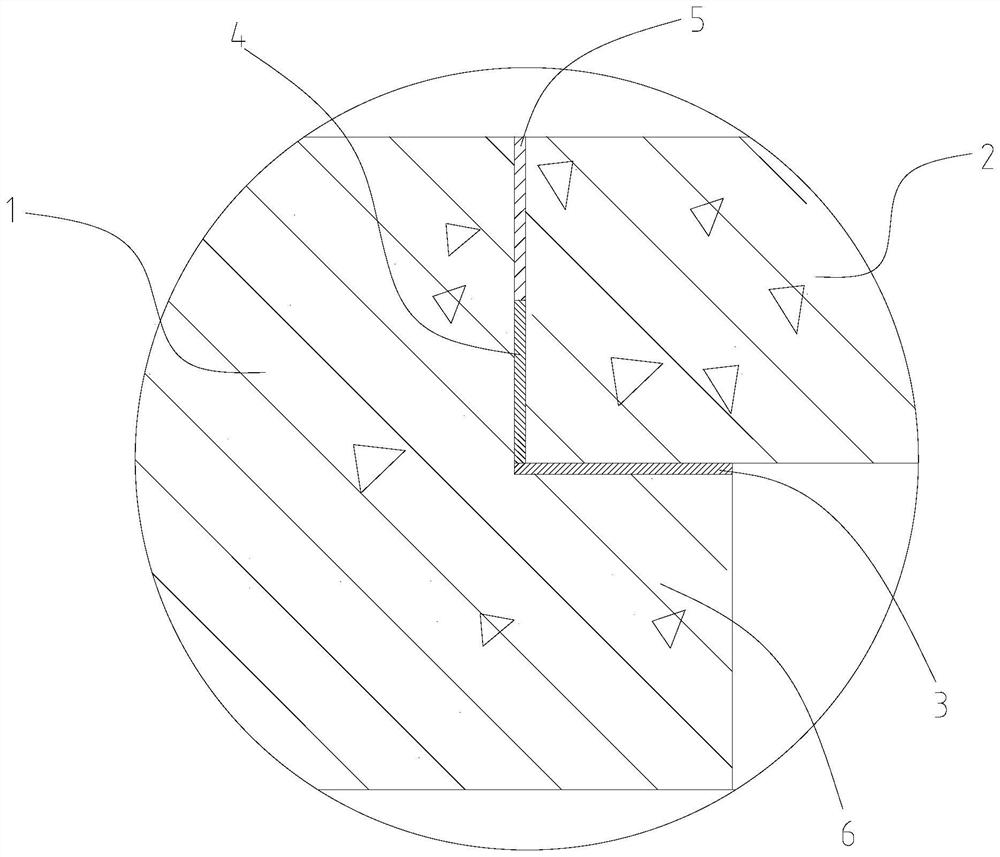

[0032] Such as figure 1 , 2 , 4, the prefabricated slab 2 is a concrete slab, and its size length × width × thickness is 3400mm × 2800mm × 300mm. Two adjacent prefabricated slabs 2 in the prefabricated slab group are tensioned and connected to each other through the connecting piece 8. One or both ends of the prefabricated slabs 2 are provided with wedge-shaped grooves, and the wedge-shaped grooves at the ends of two adjacent prefabricated slabs 2 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com