High-strength corrosion-resistant bolt and production process thereof

A production process and high-strength technology, applied in the direction of bolts, screws, nuts, etc., to achieve the effect of reasonable process steps, avoid thermal cracking, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

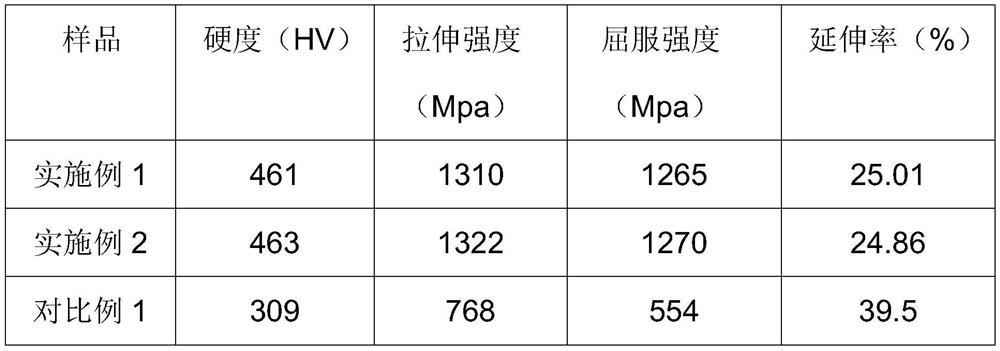

Examples

Embodiment 1

[0034] Described production process, comprises the following steps:

[0035] (1) Pretreatment: after surface cleaning, grinding and polishing of Ni, Cr, Nb, Mo, Ti, Al and Fe raw materials, they are cleaned with deionized water for many times, then ultrasonically cleaned with absolute ethanol, and dried Dry standby; Among them, the raw materials for making high-strength corrosion-resistant bolts include the following components in parts by weight: Ni 46%, Cr 17%, Nb 5%, Mo 2.5%, Ti 0.5%, Al 0.3%, C≦0.03% ,S≦0.01%, the rest is Fe;

[0036] (2) Smelting: put the Ti raw material after the above pretreatment into the crucible in the high vacuum electric arc furnace, put the Ni, Cr, Nb, Mo, Al, Fe raw materials after the above pretreatment into the crucible in the high vacuum electric arc furnace In other crucibles, the placement rules of Ni, Cr, Nb, Mo, Al, Fe raw materials are as follows: metal raw materials with high melting point are placed on the upper part of the crucible, a...

Embodiment 2

[0041] Described production process, comprises the following steps:

[0042] (1) Pretreatment: after surface cleaning, grinding and polishing of Ni, Cr, Nb, Mo, Ti, Al and Fe raw materials, they are cleaned with deionized water for many times, then ultrasonically cleaned with absolute ethanol, and dried Dry standby; Among them, the raw materials for making high-strength corrosion-resistant bolts include the following components in parts by weight: Ni 50%, Cr 16%, Nb 4%, Mo 2%, Ti 0.5%, Al 0.4%, C≦0.03% ,S≦0.01%, the rest is Fe;

[0043] (2) Smelting: put the Ti raw material after the above pretreatment into the crucible in the high vacuum electric arc furnace, put the Ni, Cr, Nb, Mo, Al, Fe raw materials after the above pretreatment into the crucible in the high vacuum electric arc furnace In other crucibles, the placement rules of Ni, Cr, Nb, Mo, Al, Fe raw materials are as follows: metal raw materials with high melting point are placed on the upper part of the crucible, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com