Self-rectification memristor array and preparation method and application thereof

A memristor and self-rectification technology, applied in the field of microelectronics, can solve problems such as inapplicability of device solutions, achieve the effects of reducing mutual influence, suppressing leakage current effects, and increasing storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

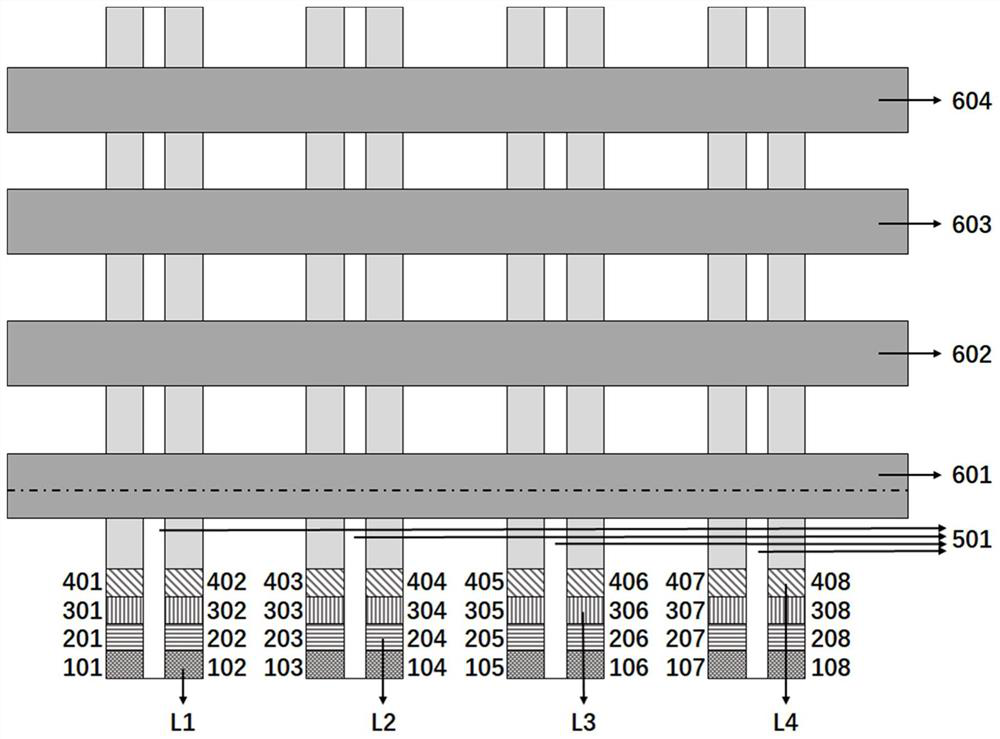

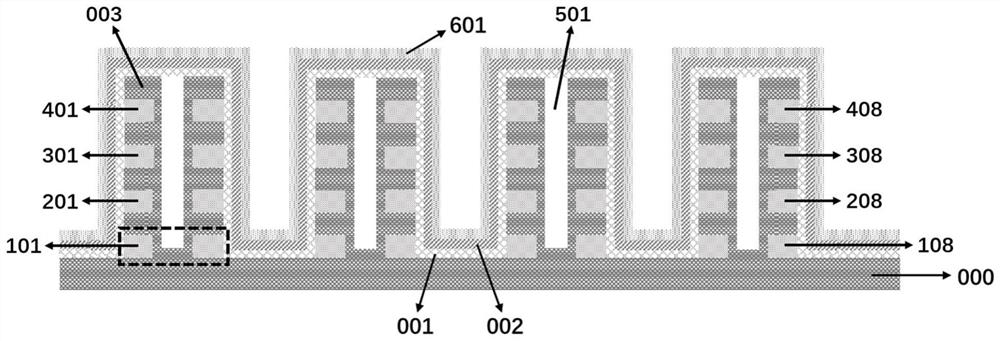

[0047] On the other hand, an embodiment of the present invention provides a method for preparing the above-mentioned self-rectifying memristor array, combining Figure 4 and Figure 7 As shown, it includes the following steps:

[0048] S1. On the substrate 000, use a preset mask to lithography the pattern of the first layer of the first electrode layer to prepare the first layer of the first electrode layer T101, and then grow the substrate 000 with the first electrode layer T101 Prepare the first layer of insulating layer 003 on it.

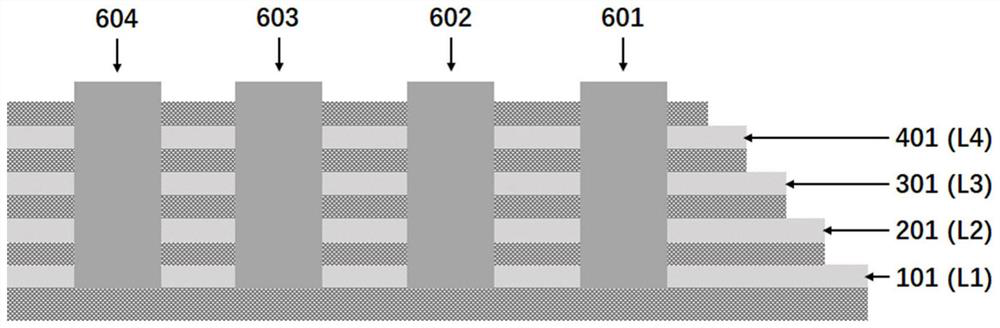

[0049] S2. Repeatedly and alternately grow the first electrode layer and the insulating layer until the predetermined number of layers is reached, such as Figure 5 As shown, the predetermined number of layers takes 4 layers as an example to obtain 4 first electrode layers (respectively T101, T201, T301 and T401) and 4 insulating layers 003.

[0050] Specifically, the first electrode layer can be prepared by sputtering, electron beam evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com