Plant cheese compound thickening agent and application thereof

A thickener and cheese technology, applied in the plant-based field, can solve the problems of poor formability, poor foldability, cumbersome processing technology, etc., and achieve the effects of improving flavor and taste, improving texture and shape, and simplifying processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

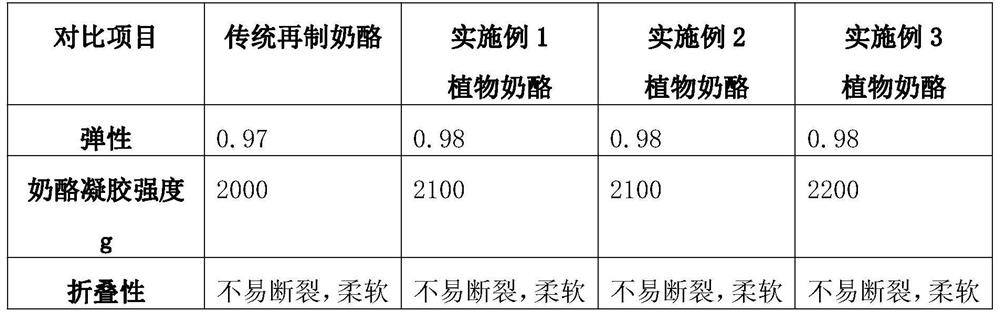

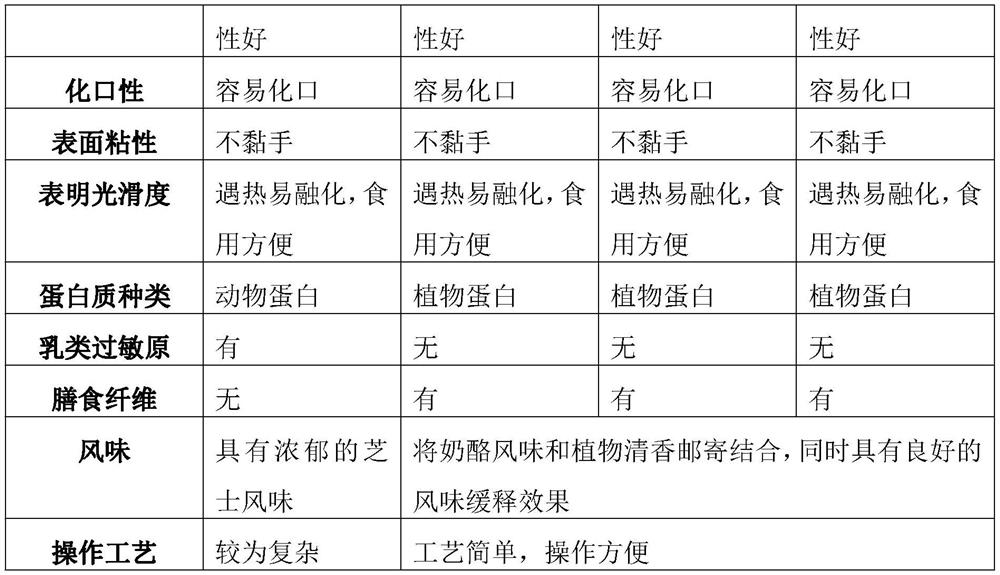

Examples

Embodiment 1

[0032] This embodiment provides a vegetable cheese compound thickener, which consists of the following components in terms of weight percentage:

[0033] Hydroxypropyl Distarch Phosphate 50%;

[0034] Oxidized hydroxypropyl starch 25%;

[0035] Sodium starch octenyl succinate 10%;

[0036] Porous starch 3%;

[0037] Emulsifier 2%;

[0038] Colloid 2%.

[0039] Wherein: the raw material of hydroxypropyl distarch phosphate is potato.

[0040] The raw material of oxidized hydroxypropyl starch is cassava.

[0041] The raw material of sodium starch octenyl succinate is potato.

[0042] The raw material of porous starch is potato.

[0043] Emulsifiers are mono- and di-fatty acid glycerides.

[0044] The colloid is sodium carboxymethyl cellulose.

[0045] The preparation method of the above-mentioned vegetable cheese compound thickener comprises weighing hydroxypropyl distarch phosphate, oxidized hydroxypropyl starch, sodium starch octenyl succinate, porous starch, emulsifie...

Embodiment 2

[0053] This embodiment provides a vegetable cheese compound thickener, which consists of the following components in terms of weight percentage:

[0054] Hydroxypropyl Distarch Phosphate 60%;

[0055] Oxidized hydroxypropyl starch 20%;

[0056] Sodium starch octenyl succinate 5%;

[0057] Porous starch 8%;

[0058] Emulsifier 5%;

[0059] Colloid 5%.

[0060] Wherein: the raw material of hydroxypropyl distarch phosphate is cassava.

[0061] The raw material of oxidized hydroxypropyl starch is cassava.

[0062] The raw material of sodium starch octenyl succinate is cassava.

[0063] The raw material of the porous starch is corn.

[0064] The emulsifier is polyglycerol ester.

[0065] The colloid is xanthan gum.

[0066] The preparation method of the above-mentioned vegetable cheese compound thickener comprises weighing hydroxypropyl distarch phosphate, oxidized hydroxypropyl starch, sodium starch octenyl succinate, porous starch, emulsifier, and colloid according to th...

Embodiment 3

[0074] This embodiment provides a vegetable cheese compound thickener, which consists of the following components in terms of weight percentage:

[0075] Hydroxypropyl Distarch Phosphate 55%;

[0076] Oxidized hydroxypropyl starch 22%;

[0077] Sodium starch octenyl succinate 8%;

[0078] Porous starch 5%;

[0079] Emulsifier 3%;

[0080] Colloid 3%.

[0081] Wherein: the raw material of hydroxypropyl distarch phosphate is potato and cassava.

[0082] The raw material of oxidized hydroxypropyl starch is cassava.

[0083] The raw materials of sodium starch octenyl succinate are potatoes and cassava.

[0084] The raw materials of porous starch are potato and corn.

[0085] Emulsifiers are mono- and di-fatty acid glycerides and polyglycerides.

[0086] The colloid is carrageenan.

[0087] The preparation method of the above-mentioned vegetable cheese compound thickener comprises weighing hydroxypropyl distarch phosphate, oxidized hydroxypropyl starch, sodium starch octen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com