Harm-reducing full-particle filter stick as well as preparation method and application thereof

A full particle and filter rod technology, applied in applications, e-liquid filter elements, tobacco, etc., can solve the problem that the quality stability and hardness index of filter rods are difficult to meet the requirements, the effect of particles is difficult to be fully exerted, and the amount of particles added cannot be precisely controlled, etc. Problems, to achieve the effect of diversification of functions, satisfying continuous mass production, and simple form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

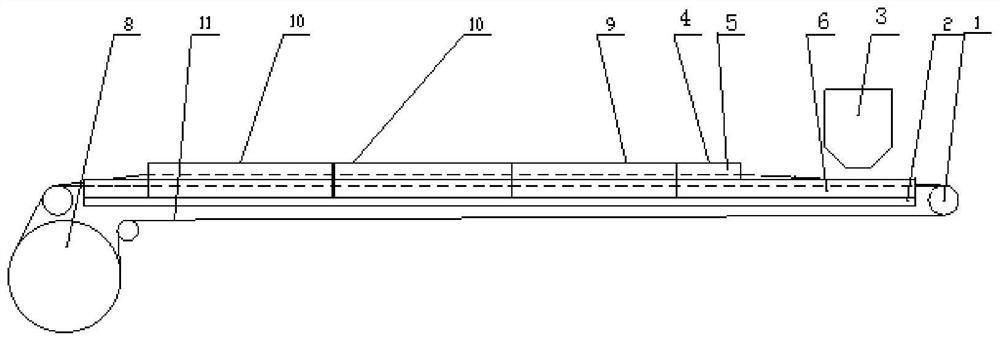

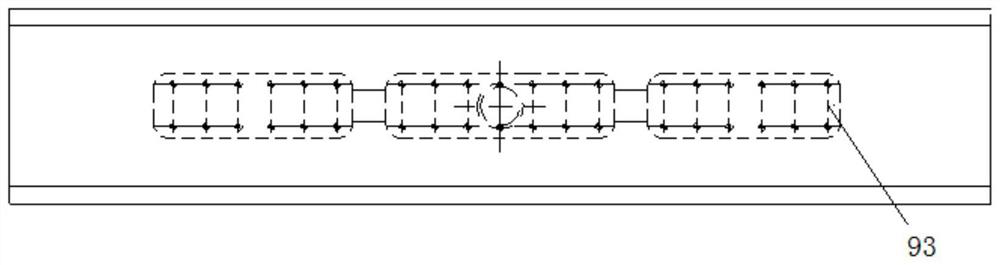

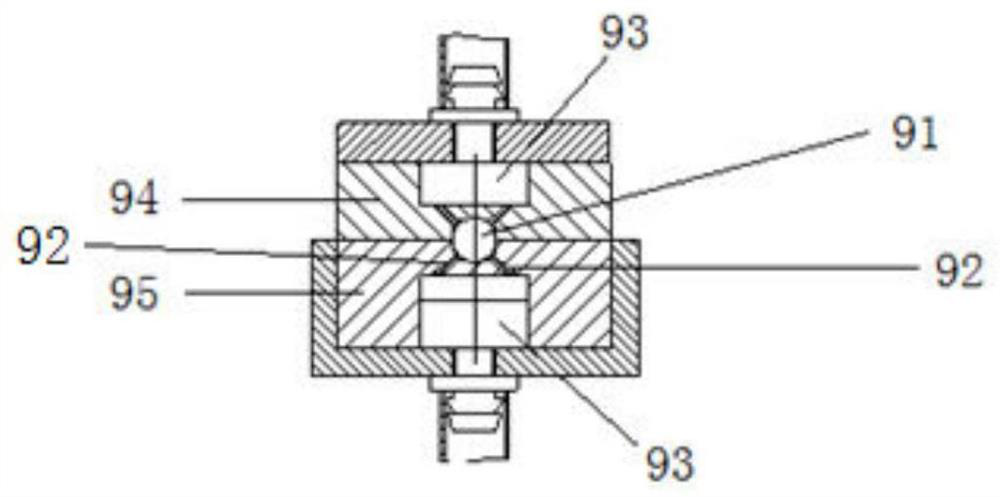

[0070] Such as figure 1 As shown, Example 1 of the equipment for preparing full-grain filter rods of the present invention includes a mesh conveyor belt 11 installed on a support 2, and a feeding device 3, a preforming device 4, and a curing molding device are sequentially installed above the mesh conveyor belt 11. Device 9 , cooling / drying assembly 10 (the cooling / drying assembly is a modular assembly, and 1 to 10 groups can be provided as required, and two groups are provided in this embodiment), driving wheel 8 .

[0071] The net conveyor belt 11 includes an upper conveyor belt and a lower conveyor belt connected as one, and the two ends of the mesh conveyor belt are horizontally supported on the guide wheel 1 and the driving wheel 12, and the upper conveyor belt is fed by the feeding device 3. mouth, and pass through the preforming device 4, the solidifying forming device 8, and the cooling / drying assembly 10 in sequence.

[0072] The bottom of the feeding device 3 is pro...

Embodiment 2

[0080] Such as Figure 7 As shown, Embodiment 2 of the equipment for preparing full-grain filter rods of the present invention is roughly the same as Embodiment 1, except that a cutting and finishing device 12 is provided at the output end of the cooling / drying assembly. The cutting and sorting device 12 cuts and sorts the formed unwrapped full particle filter rod 7 into boxes. The cutting and finishing device 12 can be a common cutting unit of an existing filter rod forming machine, and can also be modified accordingly according to actual needs.

Embodiment 3

[0082] Such as Figure 8 As shown, Embodiment 3 of the equipment for preparing full-grain filter rods of the present invention is roughly the same as Embodiment 1, except that the output end of the cooling / drying assembly 10 is connected to the wrapping device 13 and the cutting and finishing device 12 in sequence. In this embodiment, The paper wrapping device 13 is preferably an existing filter rod forming machine 15. The unwrapped full-grain filter rod 7 and the forming paper 151 are fed into the forming machine bong 152 in a certain way for forming, and then passed through the cutting and finishing device. 13 cutting and sorting into boxes to form a full particle filter rod 153 wrapped in paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com