Titanium-aluminum alloy hot forging forming method and die

A technology of titanium-aluminum alloy and forming dies, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of high price, high cost, and difficult processing, so as to improve strength, toughness, and service life , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

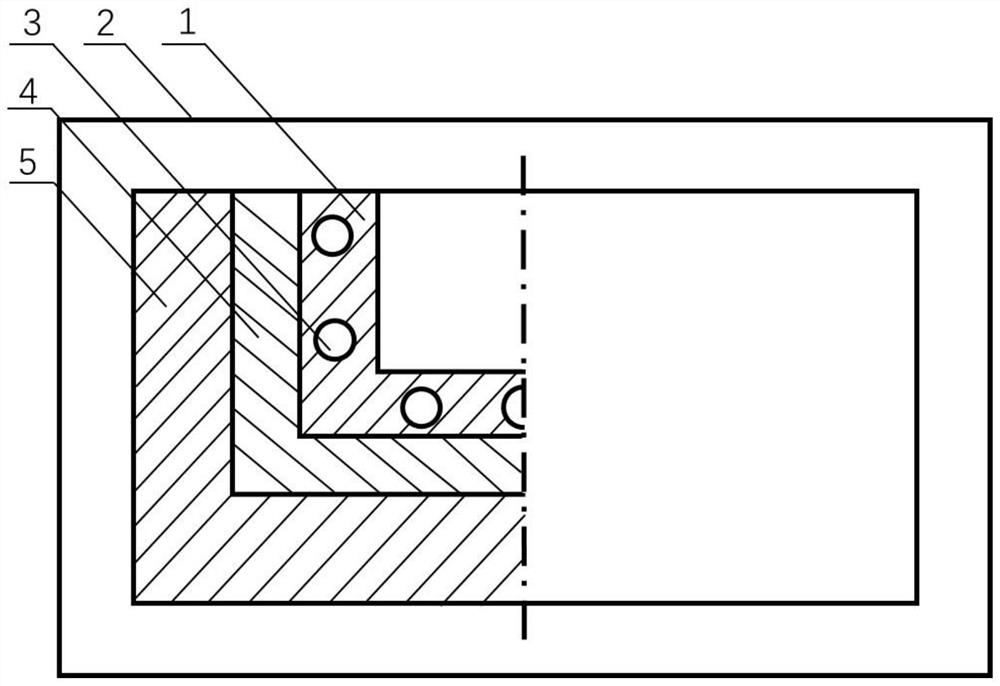

[0037] This embodiment provides a titanium aluminum alloy hot forging forming die, as attached figure 1 As shown, a titanium-aluminum alloy hot forging forming die includes an outer mold 5 and an inner mold arranged from outside to inside, and the inner mold is composed of a second inner mold 4 and a first inner mold 1 that are tightly combined from outside to inside, A heating hole 3 is installed inside the first inner mold 1 , and both the outer mold and the inner mold are arranged in the mold frame 2 . In order to form a temperature gradient between the inner and outer molds, heat-insulating ceramic fibers are laid between the outer mold, the second inner mold and the first inner mold, with a thickness of 1-5mm.

[0038] Wherein, the first inner mold is made of a material with high temperature resistance, high temperature yield strength of 900°C greater than 200MPa, and high thermal expansion rate. Generally, high temperature alloy or heat-resistant steel material can be se...

Embodiment 2

[0042] This embodiment provides a titanium-aluminum alloy hot forging forming method for aeroengine blades, which is to wrap a titanium-aluminum blank with a diameter of 30mm in glass heat-insulating fibers, and the thickness of a single layer of glass heat-insulating fibers wrapped in the blank is 1mm, and the rod is first wrapped The material core layer is wrapped with 4 layers of glass heat-insulating fibers, with a thickness of 4mm. After being tightly compressed by a roll baler, the actual thickness of the wrapped glass heat-insulating fiber layer is 2mm. Put it in a heating furnace and heat it at 8000°C for 15 minutes, take it out and cool it, and then wrap the glass insulation fiber layer twice, wrap 2 layers, the thickness is 2mm, the second layer of glass fiber insulation layer can be wrapped according to the shape, no need to compress and wrap the blank . The blank is wrapped with 6 layers of fiberglass insulation, but the actual thickness of the insulation is 4mm. ...

Embodiment 3

[0046] This embodiment provides a titanium-aluminum alloy hot forging forming method for aeroengine blades, which is to wrap a titanium-aluminum blank with a diameter of 50mm in glass heat-insulating fibers, and the thickness of a single layer of glass heat-insulating fibers wrapped in the blank is 1mm, and the rod is first wrapped The material core layer is wrapped with 6 layers of glass heat-insulating fibers, with a thickness of 6mm. After compact compression, the actual thickness of the wrapped glass heat-insulating fiber layer is 3mm. Put it in a heating furnace and heat it at 1000°C for 50 minutes, take it out and cool it, and wrap the glass insulation fiber layer twice, wrap 2 layers, the thickness is 2mm, the second layer of glass fiber insulation layer can be wrapped according to the shape, no need to compress and wrap the blank . The blank is wrapped with 6 layers of glass fiber heat insulation layer, but the actual thickness of the heat insulation layer is 5mm. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com