Three-dimensional enclosure bulkhead member coupling type paper box

A coupled, one-dimensional enclosure technology, applied to bottle/can parts, containers to prevent mechanical damage, rigid containers, etc., can solve the problems of low efficiency of resource recycling, low efficiency of installation and disassembly, and overall stability of the structure Poor performance and other problems, to achieve the effect of recycling resources, reducing tree felling, improving stability and efficiency of installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

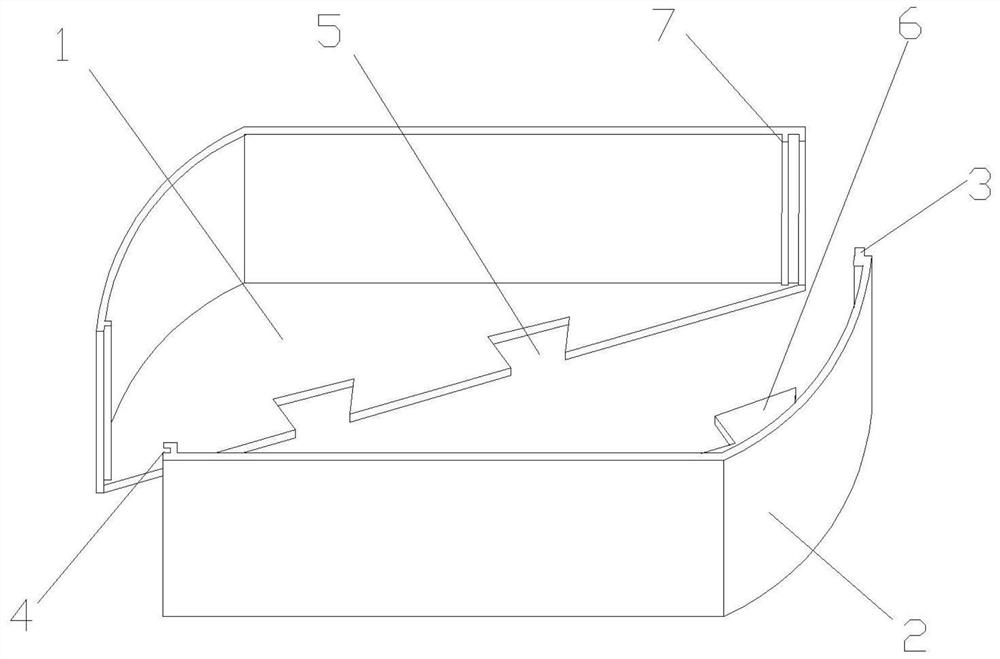

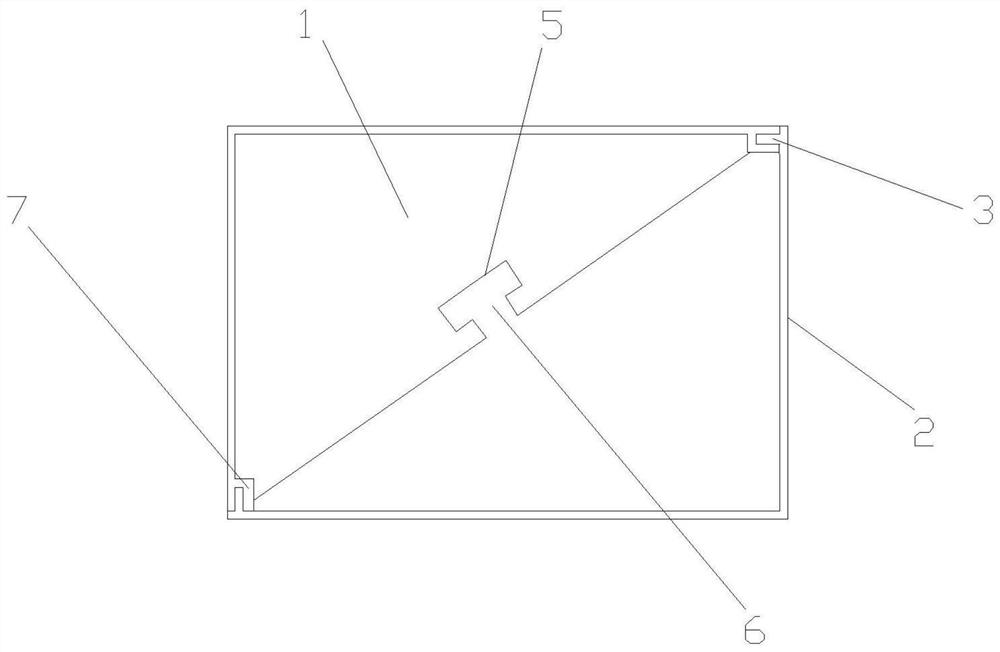

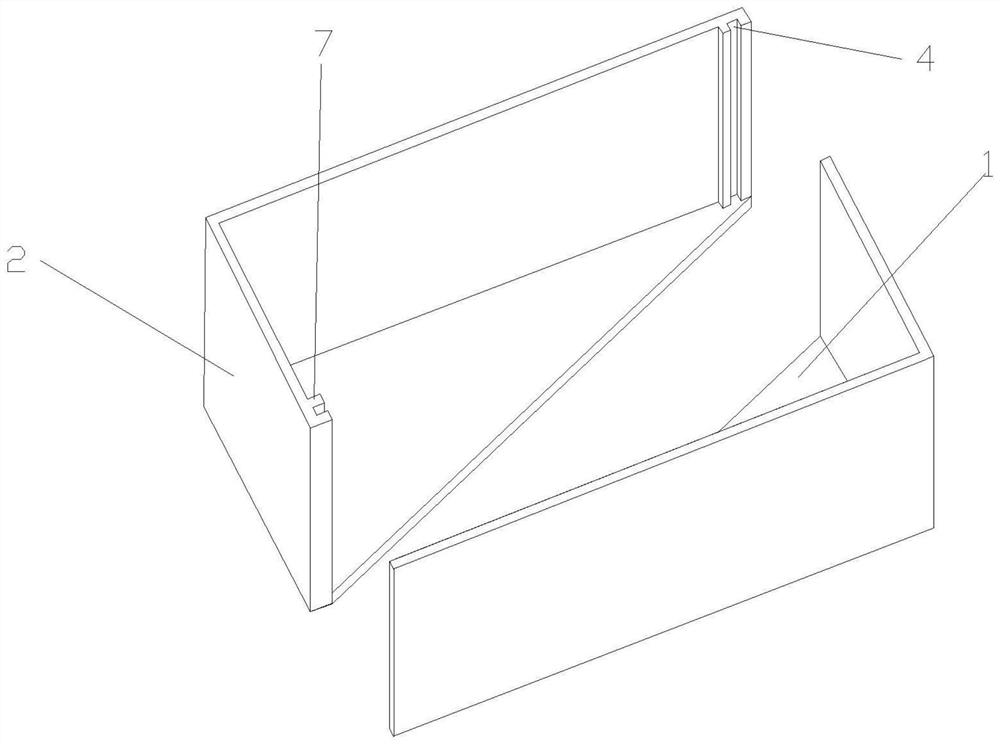

[0033] The following will combine Figure 1-11 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0034]In the present invention, the mutually symmetrical three-dimensional surrounding wall component A and the three-dimensional surrounding wall component B are nested with each other or connected as a whole through a third-party connecting piece, and then formed by thermocompression molding of plant fiber materials mixed with waste paper pulp and straw grinding materials. Compatible cover plates form various packaging cartons. The three-dimensional surrounding wall components are designed to realize the necessity of overlapping in the compressed space. The combination of AB components can form cuboids, cubes, cylinders, elliptical cylinders, rhombus cylinders and a A three-dimensional volume whose opposite is a plane a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com