High-toughness narrow-hardenability gear steel with 20CrMnTiH, bar and manufacturing method of high-toughness narrow-hardenability gear steel

A technology of hardenable belt and manufacturing method, which is applied in the fields of bar and its manufacture, and steel, and achieves the effects of high pairing meshing performance, excellent mechanical properties and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

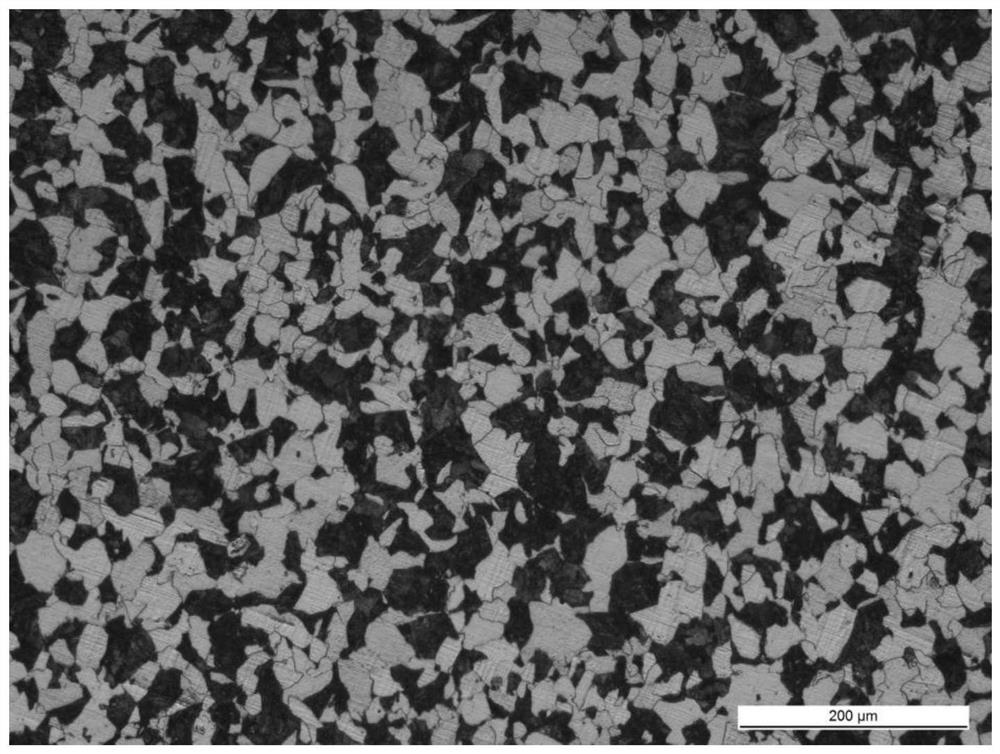

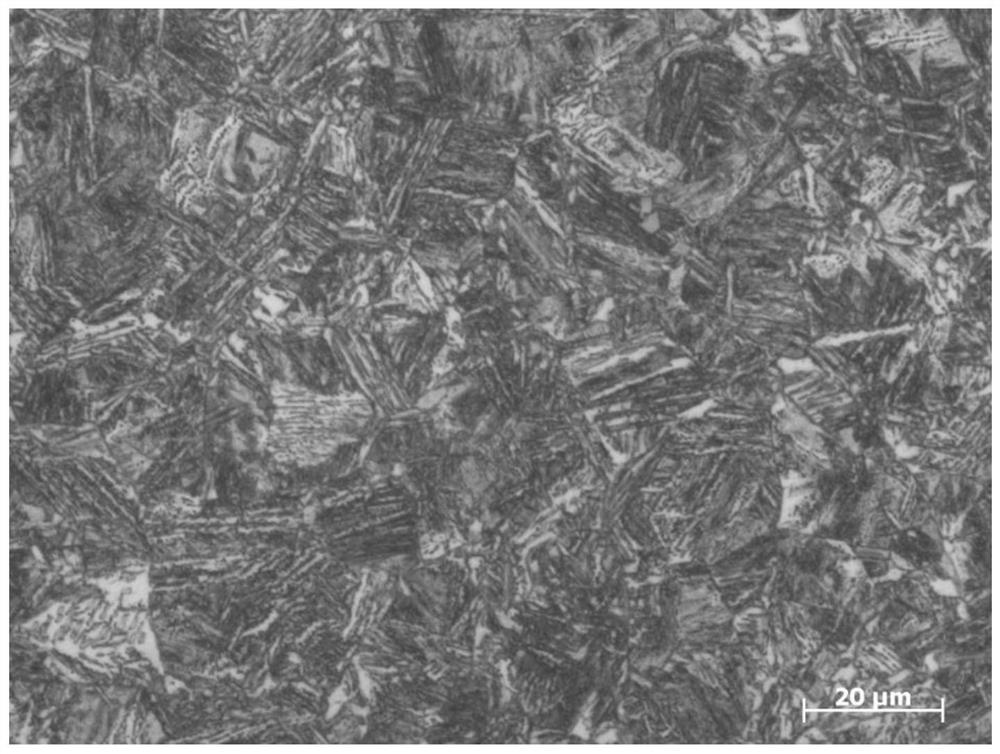

Image

Examples

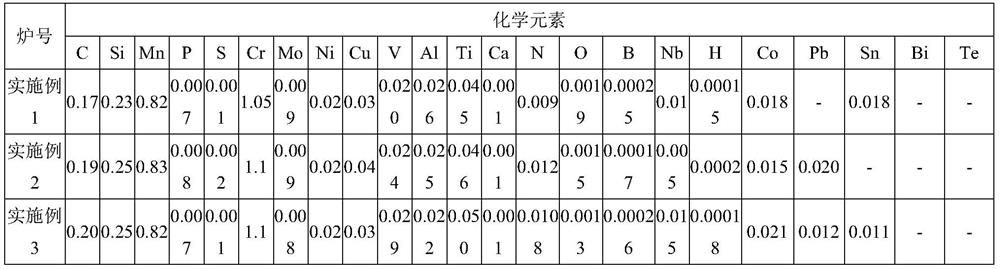

Embodiment 1-6 and comparative example 1

[0063] The bar of embodiment 1-6 all adopts following steps to make:

[0064] (1) Smelting according to the chemical composition shown in Table 1: use electric furnace or converter for smelting, and cast into continuous casting slabs or steel ingots; in the casting process, die casting or continuous casting can be used.

[0065] (2) Heating: Control the heating temperature to 1050-1250°C.

[0066] (3) Forging or rolling: Control the final rolling or final forging temperature to ≥800°C. Among them, if forging is performed, the final dimensions such as forging can be directly forged during the forging process. If rolled, during the rolling process, the billet can be rolled directly to the final specification, or the billet can be rolled to the specified intermediate billet size, and then heated and rolled to the final finished product size.

[0067] (4) Quenching + tempering: The austenitizing temperature for quenching is 840-1050°C, and oil quenching is used after austenitizi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com