BIM (Building Information Modeling)-based tree-shaped column node steel bar arrangement structure and construction method

A construction method and a technology of column joints, applied to structural elements, building components, building structures, etc., can solve problems such as difficult to determine the length of steel bar blanking, inaccurate sleeve arrangement and positioning, and complex force at joints, etc., to achieve Avoid steel bar collisions and cutting difficulties, enhance flexibility and expand, and achieve continuous and smooth shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

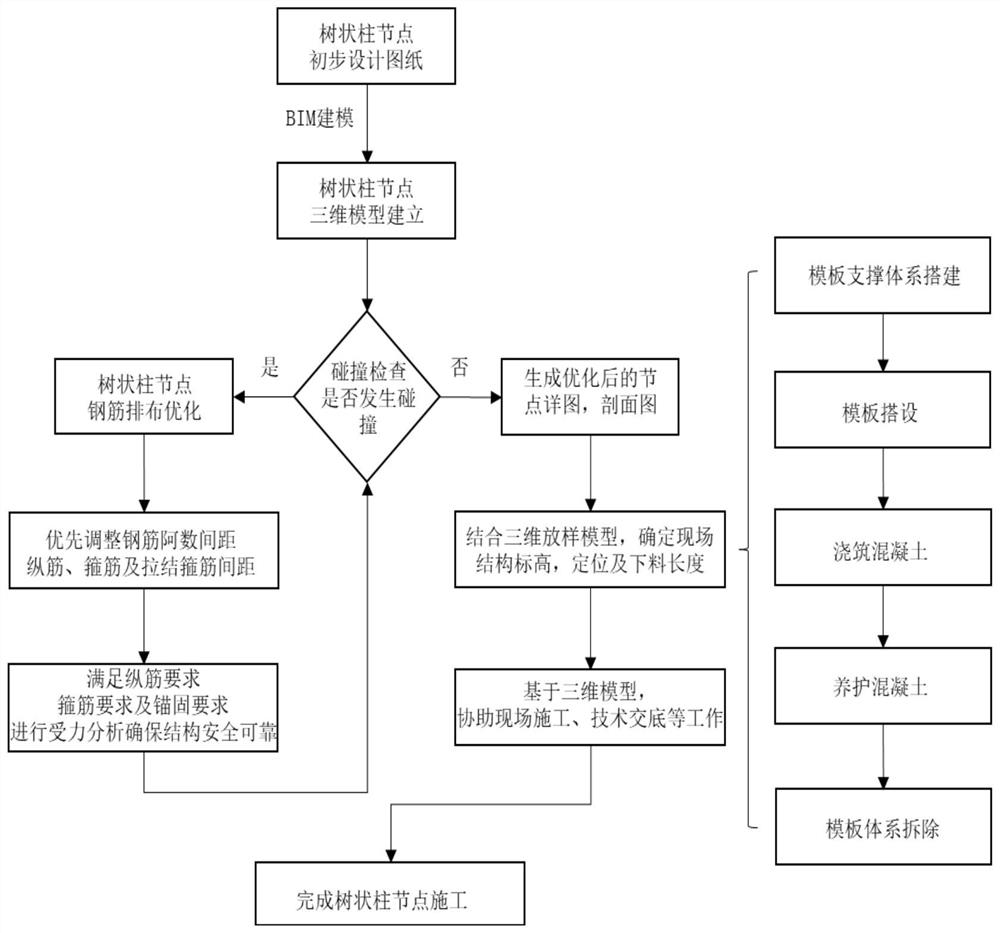

[0044] The embodiment of the present invention discloses a BIM-based construction method for arranging steel bars at tree-like column nodes, referring to figure 1 , including the following construction steps:

[0045] Step 1: Preliminarily arrange the reinforcement structure at the node of the tree-like column, and carry out preliminary design records through two-dimensional drawings, and then use BIM software to draw a three-dimensional model drawing with reference to the two-dimensional drawings, and establish a preliminary reinforcement arrangement model;

[0046] Step 2: Calculate the collision parameters between the steel bars according to the three-dimensional model of the steel bar arrangement structure established by the BIM software. The collision parameters include the number of collisions and the collision depth, optimize the steel bar arrangement structure according to the collision parameters, including adjusting the circle Number and spacing reduce collision para...

Embodiment 2

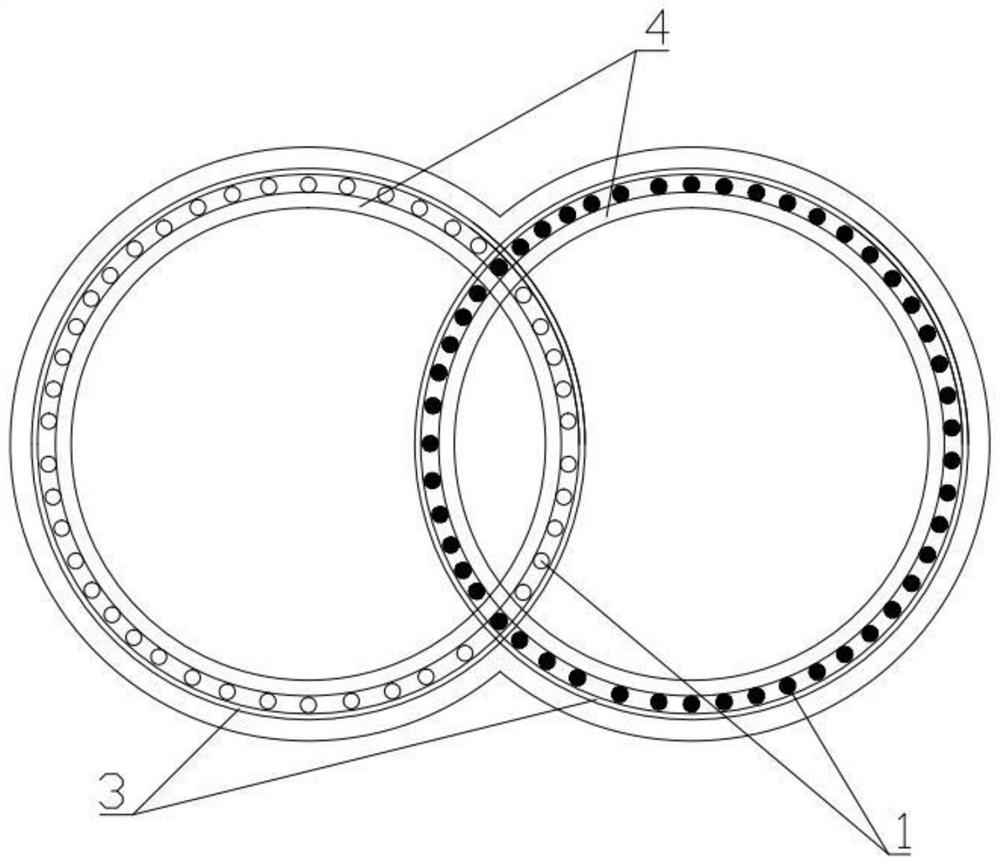

[0053] The preliminary reinforcement arrangement model described in step 1 includes 1 arrangement of outer longitudinal bars, 2 arrangements of inner longitudinal bars, 3 arrangements of outer stirrups and 4 arrangements of inner stirrups, and the minimum number of steel bars required is determined by force calculation, according to A minimum number of bars are arranged.

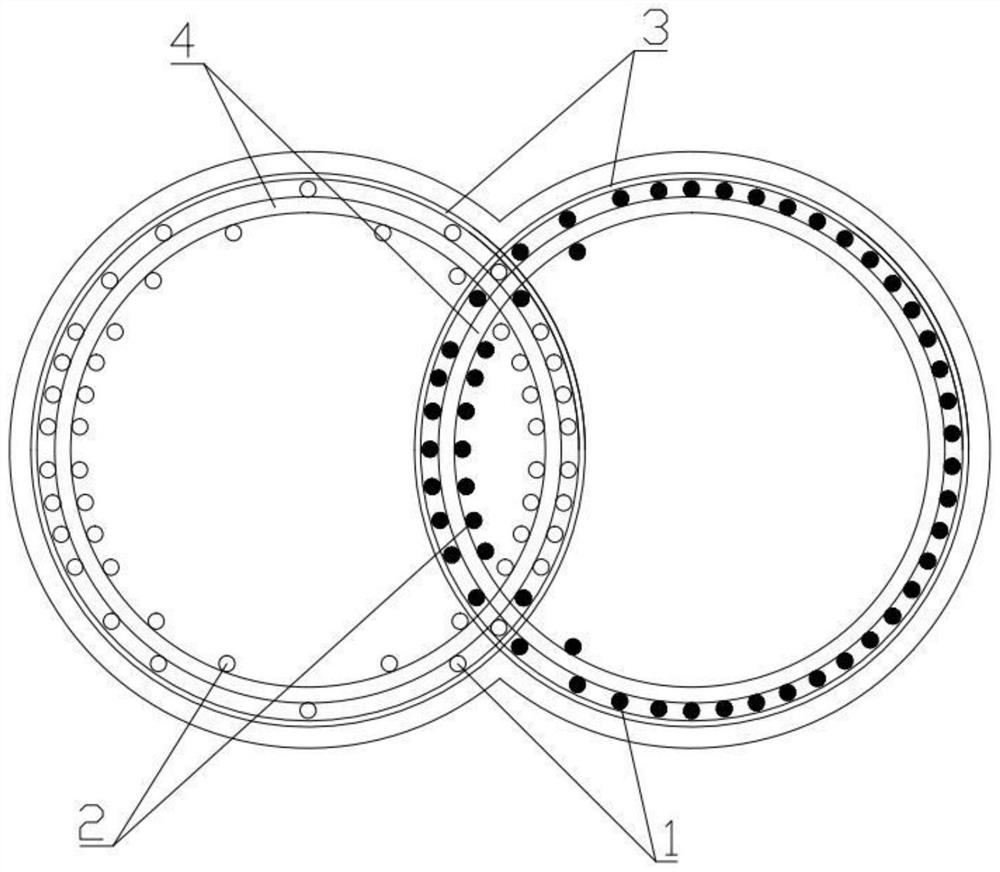

[0054] The optimized steel bar arrangement structure described in step 2 is adjusted by human-computer interaction, and the position of the steel bar is manually adjusted to avoid other steel bars to the greatest extent. During the adjustment process, the computer displays the collision parameters in real time and automatically calculates the force of the steel bar. .

[0055] refer to figure 2 with 3 , the adjustment of the position of the reinforcement includes the adjustment of the spacing between the reinforcement and the adjustment of the reinforcement ring layer, and the adjustment of the spacing be...

Embodiment 3

[0062] The BIM software includes Revit Structure, Navisworks and Lumion, and the collision parameters and stress conditions are displayed in real time, including numerical display and chromatogram display.

[0063] The template uses the following scheme:

[0064]

[0065] Under the premise of ensuring the integrity and safety of the structure, the collision rate of steel bars using this tree-like column node reinforcement arrangement method is reduced from 40.0% before optimization to 5.0%, and the actual collision rate is 3.0% during the on-site supervision and inspection process. The speed has been significantly increased, from 10 days to 8 days, and the standard floor height has been reduced from 3.9m to 3.6m while keeping the net height unchanged, and the construction cost per square meter can be reduced by 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com