Ultra-deep sulfur-containing gas well shaft sulfur deposition treatment method

A sulfur deposition and wellbore technology, which is applied in the field of ultra-deep sulfur-containing gas well wellbore sulfur deposition control, can solve the problems of high risk in construction operations and high cost of sulfur deposition, and achieve the effects of authentic and reliable data, low operating costs, and accelerated and rapid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

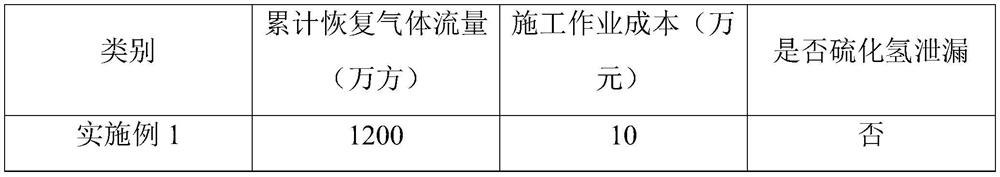

[0046] Treatment of sulfur deposition in well 1#

[0047] A method for treating sulfur deposition in the wellbore of an ultra-deep sulfur-containing gas well. The wellbore of the 1# gas well is 6,800 meters deep, and the gas release capacity due to sulfur deposition has dropped from 400,000 cubic meters per day to 200,000 cubic meters per day, and continues to decline;

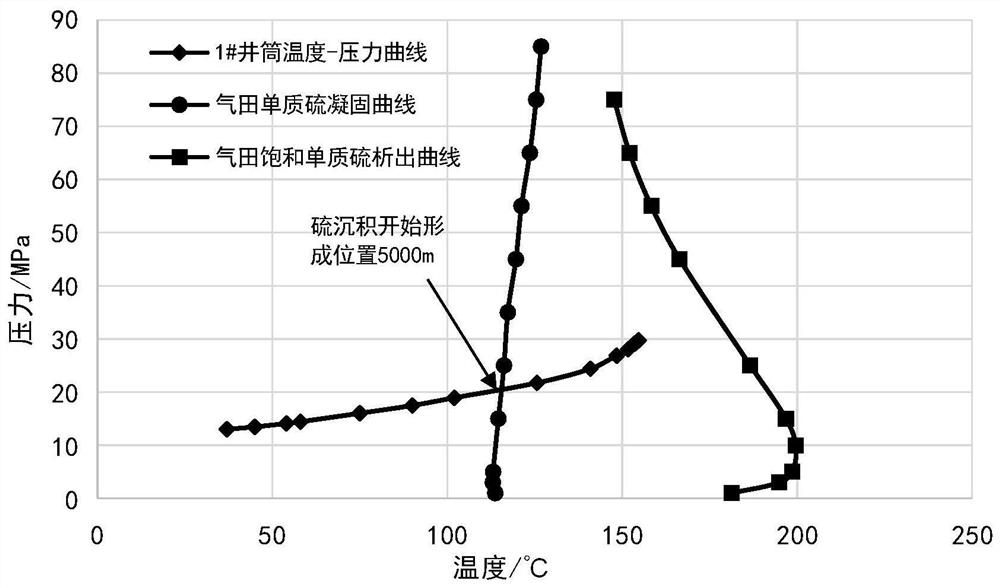

[0048] Lower the pressure gauge and thermometer into the wellbore through the steel wire to determine the wellbore pressure-temperature curve, and use the gas well elemental sulfur phase diagram to determine the solidification line of elemental sulfur. and temperature, the corresponding wellbore depth is 5000 meters where sulfur deposition is formed, such as figure 1 shown;

[0049] Calculate the amount of sulfur solvent according to the sulfur deposition position described in the previous step, wherein the amount of sulfur solvent is the upper wellbore volume of the sulfur deposition formation position in ...

Embodiment 2

[0054] Treatment of Sulfur Deposition in Well 2#

[0055] A method for treating sulfur deposition in the wellbore of an ultra-deep sulfur-containing gas well. The wellbore of the 2# gas well is 6850 meters deep, and the gas release capacity due to sulfur deposition has dropped from 400,000 cubic meters per day to 200,000 cubic meters per day, and continues to decline;

[0056] Lower the pressure gauge and thermometer into the wellbore through the steel wire to determine the wellbore pressure-temperature curve, and use the gas well elemental sulfur phase diagram to determine the solidification line of elemental sulfur. and temperature, the corresponding wellbore depth is 4500 meters where sulfur deposition is formed;

[0057] Calculate the amount of sulfur solvent according to the sulfur deposition position described in the previous step, wherein the amount of sulfur solvent is the upper wellbore volume of the sulfur deposition formation position in the wellbore of the gas we...

Embodiment 3

[0061] Treatment of Sulfur Deposition in Well 3#

[0062] A method for treating sulfur deposition in the wellbore of an ultra-deep sulfur-containing gas well. The wellbore of the 3# gas well is 6,500 meters deep, and the gas release capacity due to sulfur deposition has dropped from 200,000 cubic meters per day to 50,000 cubic meters per day, and continues to decline;

[0063] Lower the pressure gauge and thermometer into the wellbore through the steel wire to determine the wellbore pressure-temperature curve, and use the gas well elemental sulfur phase diagram to determine the solidification line of elemental sulfur. and temperature, the corresponding wellbore depth is 5200 meters where the sulfur deposition is formed;

[0064] Calculate the amount of sulfur solvent according to the sulfur deposition position described in the previous step, wherein the amount of sulfur solvent is the upper wellbore volume of the sulfur deposition formation position in the wellbore of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com