Efficient thick copper plate solder resist printing method

A thick copper plate and solder mask technology, applied in the secondary treatment, application, coating of non-metallic protective layers of printed circuits, etc., can solve the problems of poor high temperature resistance, easy to explode, etc., and achieve fast curing speed and good curing performance. , the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

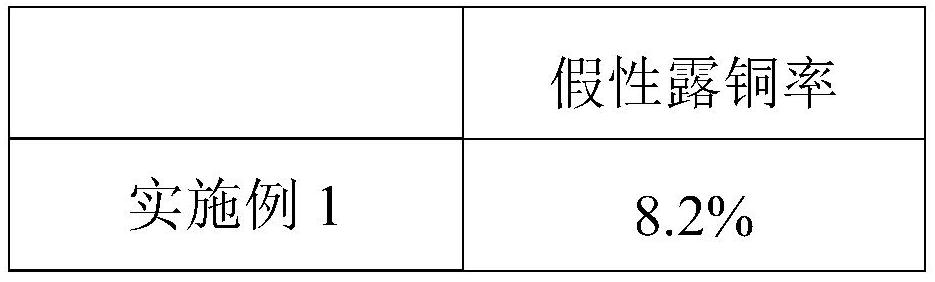

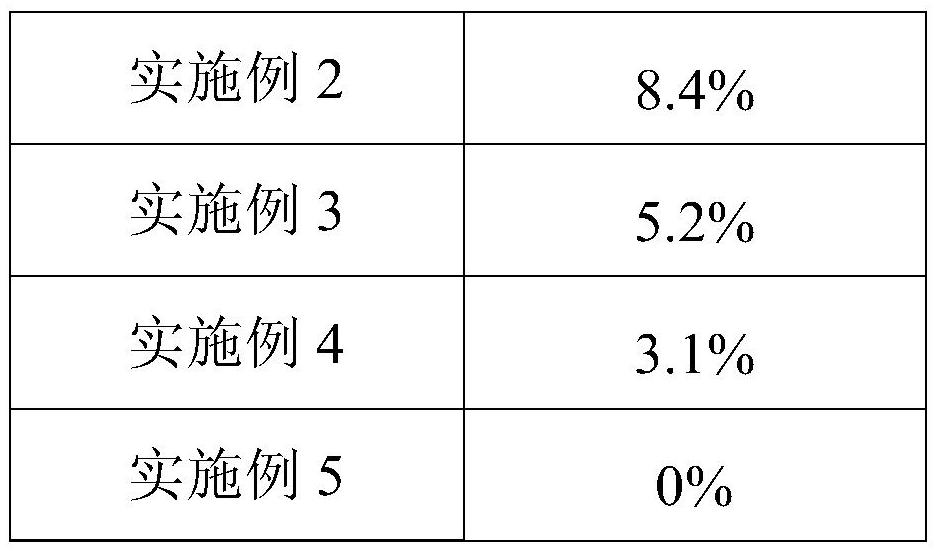

Examples

Embodiment 1

[0043] A process for preparing a solder mask for a thick copper plate, comprising the following steps:

[0044] (1) Make a copper layer area screen for the area covered by the copper layer on the surface of the circuit board;

[0045] (2) Cover the copper layer area screen on the thick copper plate treated with volcanic ash, perform screen printing once with the diluted solder resist ink, let it stand for 28 minutes, and then place it at 75 ° C to dry for 50 minutes to obtain a thick copper plate for one printing;

[0046] (3) peel off the copper layer area screen on the thick copper plate obtained in step (2), then use undiluted solder resist ink for secondary printing, let stand for 28 minutes, and finally, place it at 75 ° C to dry for 50 minutes, Obtain secondary printing thick copper plate;

[0047] (4) Expose, develop, and solidify the thick copper plate for secondary printing obtained in step (3) at high temperature to obtain a thick copper plate for solder resist, whe...

Embodiment 2

[0050] A process for preparing a solder mask for a thick copper plate, comprising the following steps:

[0051] (1) Make a copper layer area screen for the area covered by the copper layer on the surface of the circuit board;

[0052] (2) Cover the copper layer area screen on the thick copper plate treated with volcanic ash, then immerse it in the etchant horizontally for 40s, then slowly lift it out, place it on the plane and ultrasonic for 15min, the ultrasonic power is 140W, and the ultrasonic frequency is 15kHz, then, scrape off the excess etchant, let it stand for 15min, and dry it at 75°C for 28min to obtain a etched thick copper plate;

[0053] (3) screen printing the etch-repair thick copper plate obtained in step (2) with the diluted solder resist ink, let stand for 28 minutes, and then place it at 75° C. to dry for 50 minutes to obtain a printing thick copper plate;

[0054] (4) peel off the copper layer area screen on the thick copper plate obtained in step (3), th...

Embodiment 3

[0060] A process for preparing a solder mask for a thick copper plate, comprising the following steps:

[0061] (1) Make a copper layer area screen for the area covered by the copper layer on the surface of the circuit board;

[0062] (2) Cover the copper layer area screen on the thick copper plate treated with volcanic ash, then immerse it in the etchant horizontally for 40s, then slowly lift it out, place it on the plane and ultrasonic for 15min, the ultrasonic power is 140W, and the ultrasonic frequency is 15kHz, then, scrape off the excess etchant, let it stand for 15min, and dry it at 75°C for 28min to obtain a etched thick copper plate;

[0063] (3) screen printing the etch-repair thick copper plate obtained in step (2) with the diluted solder resist ink, let stand for 28 minutes, and then place it at 75° C. to dry for 50 minutes to obtain a printing thick copper plate;

[0064] (4) peel off the copper layer area screen on the thick copper plate obtained in step (3), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com