Use of silica-zirconia catalysts in processes for reducing glycidol, glycidyl esters, or both glycidol and glycidyl esters

A glycidyl ester, silica technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc., can solve inefficient operation costs, reduce market prices, Reduce oil quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-

[0081] Embodiment 1-control experiment

[0082] The above reaction procedure is used in the following examples. Soybean oil spiked with glycidyl oleate was mixed and heated to a maximum temperature of 90°C under argon. As shown in Table 2 below, the total glycidol concentration in the reaction mixture was measured over 30 minutes.

[0083] Table 2. Control experiment results

[0084] Reaction time Glycidol(ppm) adulterated soybean oil 22.35 Heat to 90°C 22.58 15 minutes 24.56 30 minutes 23.12

[0085] As shown in Table 2, there was no glycidyl / glycidyl oleate reduction in the absence of catalyst addition to the reaction mixture.

Embodiment 2

[0086] Example 2 - Silica zirconia catalyst dosage effect into reaction mixture

[0087] The catalyst synthesis and reaction methods described above are used in the following examples. Catalyst A of the present invention was added to soybean oil spiked with glycidyl oleate at 0.5%, 1.0%, 1.5% and 2.0% by weight based on the total weight of the silica-zirconia catalyst and soybean oil. The reaction mixture was mixed and heated to a maximum temperature of 90 °C under argon. As shown in Table 3 below, the concentration of total glycidol in the reaction mixture was measured before and after 30 minutes.

[0088] Table 3. Epoxide reduction at various catalyst dosages

[0089] Catalyst dosage wt% Initial glycidol (ppm) Final glycidol (ppm) 0.5 9.79 1.62 1.0 10.24

1.5 10.38

2.0 17.90

[0090] Limit of quantitation (LOQ) = 0.20ppm

[0091] As shown in Table 3, dosages as low as 0.5% by weight of the silica-zircon...

Embodiment 3

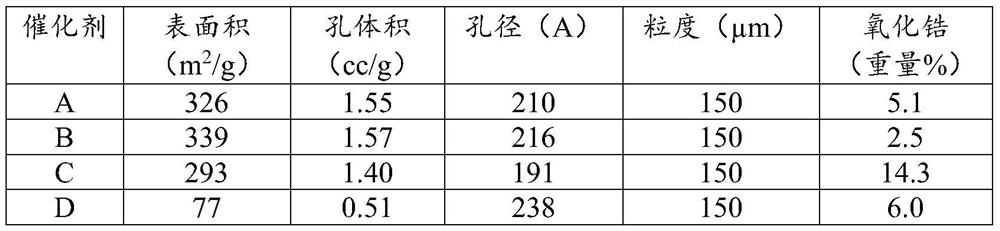

[0092] Example 3 - Zirconia Concentration and Its Effect on Total Glycidol Reduction

[0093] The catalyst synthesis and reaction methods described above are used in the following examples. Catalysts A, B, C and D of the present invention were added to soybean oil spiked with glycidyl oleate. A silica / zirconia catalyst of 2.0% by weight based on the total weight of catalyst and soybean oil was used. The reaction mixture was mixed and heated to a maximum temperature of 90 °C under argon. As shown in Table 4 below, the concentration of total glycidol in the reaction mixture was measured before and after 30 minutes.

[0094] Table 4. Glycidol reduction at various zirconia concentrations

[0095] catalyst Initial glycidol (ppm) Final glycidol (ppm) A 17.90

[0096] As shown in Table 4, increasing the concentration of zirconia on the silica base significantly improved the reduction of glycidol / glycidyl oleate in the reaction mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com