Vacuum casting furnace main shaft lifting rod protection device

A technology of protection device and lifting rod, applied in the direction of casting mold, casting mold composition, casting equipment, etc., can solve the problem of shortening the service life of the spindle, and achieve the effect of reducing the number of maintenance and cost, improving the applicability and improving the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

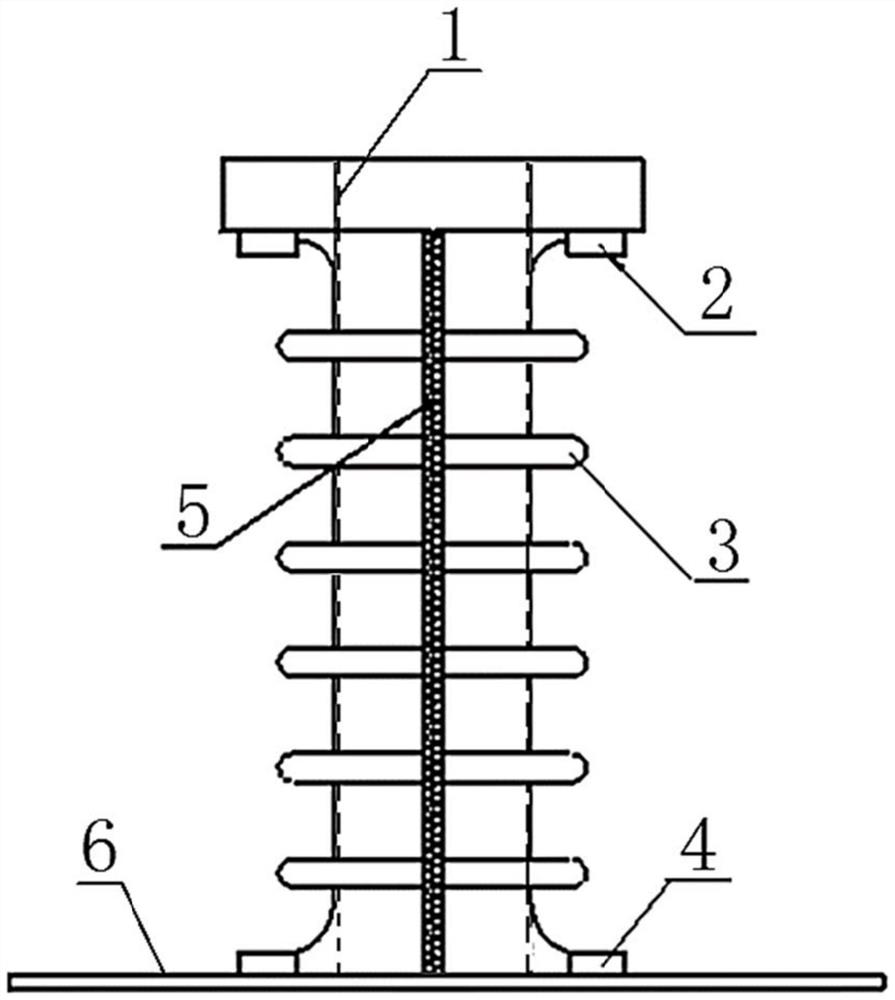

[0052] ALD three-chamber vacuum furnace

[0053] 1) Make a protective cover 2 matching the main shaft of the ALD furnace, and arrange an elastic refractory plastic material along the axial direction of the main shaft.

[0054] 2) Make the first fixing part 2 and the second fixing part 4 in the present invention, so that the top end of the protective cover 2 can be tightly connected with the bottom surface of the lifting rod table through the first fixing part 2, and the bottom end can pass through the second fixing part for one week. Part 4 is seamlessly connected with pit 6.

[0055] 3) Make the zipper 5 of the present invention, zip it from top to bottom along the axial direction of the protective cover 2, connect the protective cover 2 for one week, and keep the gap between the main shaft elevating rod 1 and the protective cover 2 at 12mm.

[0056] 4) Install the manufactured lifting rod corrugated protective cover on the outside of the main shaft lifting rod 1, fasten the...

Embodiment 2

[0060] 1) Make a supporting protective cover 2 for a large-scale 100kg vacuum furnace, and arrange an elastic refractory plastic material along the axial direction of the main shaft.

[0061] 2) Make the first fixing part 2 and the second fixing part 4 in the present invention, so that the top end of the protective cover 2 can be tightly connected with the bottom surface of the lifting rod table through the first fixing part 2, and the bottom end can pass through the second fixing part for one week. Part 4 is seamlessly connected with pit 6.

[0062] 3) Make the zipper 5 of the present invention, zip from top to bottom along the axial direction of the protective cover 2, connect the protective cover 2 for one week, and keep the gap between the main shaft elevating rod 1 and the protective cover 2 at 15 mm.

[0063] 4) Install the manufactured lifting rod corrugated protective cover on the outside of the main shaft lifting rod 1, fasten the upper and lower ends with four bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com