Method for electrocatalytic conversion of carbon dioxide by microorganisms

A technology of catalytic conversion and microbial electricity, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low efficiency of biological methods, and achieve the effect of alleviating the problem of CO2 resource utilization, improving efficiency and high current response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: microbial electrolysis cell start-up stage

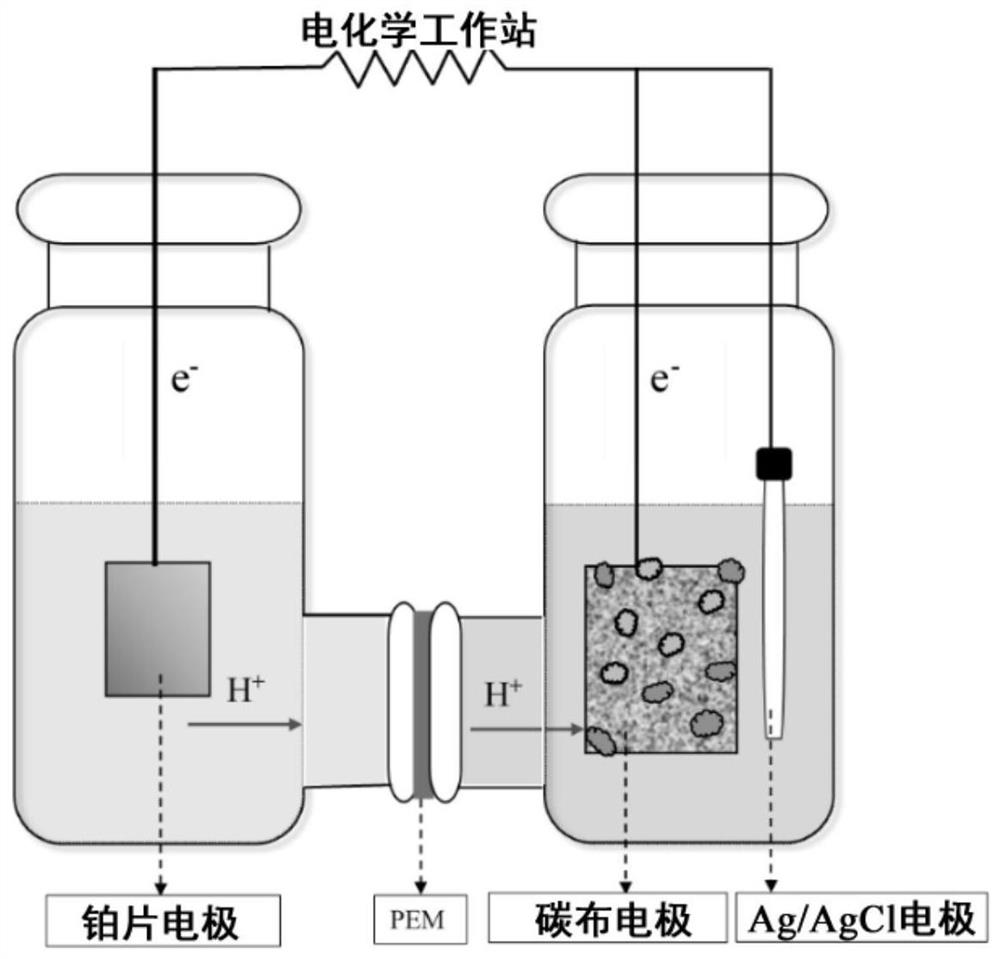

[0029] refer to figure 1 , the microbial electrolytic cell is made up of cathode chamber, anode chamber, and described cathode chamber and anode chamber are communicated by proton exchange membrane, and described proton exchange membrane refers to Nafion 117 proton exchange membrane; In described cathode chamber, carbon cloth electrode is used as cathode, The Ag / AgCl electrode is the reference electrode; the platinum sheet electrode in the anode chamber is the anode, and the distance between the cathode and the anode is 5 cm. The top of the cathode chamber is provided with an aeration port and a sampling port, the aeration port is connected with a 0.45 μm filter membrane for the filtration of microorganisms and particles, and the sampling port is used for the collection and analysis of the catholyte; the carbon cloth electrode, Ag / AgCl The electrode and the platinum sheet electrode are respectively connected wi...

Embodiment 2

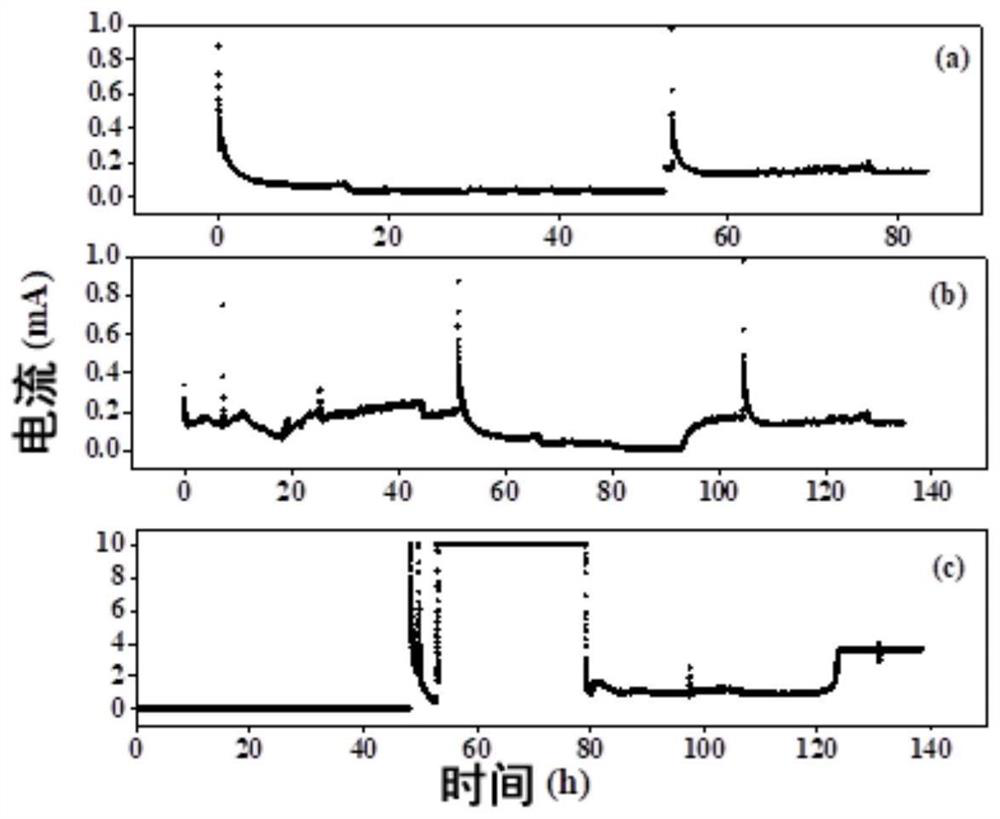

[0034] Example 2: Catalytic conversion of CO by microbial electrolysis cells at different cathode potentials 2 ability

[0035] 1. Changes in current at different potentials

[0036] After embodiment 1 microbial electrolytic cell starts successfully, catholyte chamber is replaced with new catholyte, and anode chamber is replaced with new anolyte, and it is -0.6V to run 140h under the condition of cathodic potential, and each experiment period (5 days / period) ends Afterwards, both the catholyte and the anolyte were replaced, and with 40mL min -1 into CO at a rate of 2 Gas for 15min to make the CO in the catholyte 2 The concentration reaches saturation, and the current change during operation is referred to figure 2 Middle (b). After the microbial electrolytic cell started running, 4mL was sampled from the cathode chamber every 10 hours, and the same volume of catholyte (same as in Example 1) was added, and the Shimadzu Total Organic Carbon Analyzer was used to detect inor...

Embodiment 3

[0040] Example 3: Biofilm Electrochemical Activity at Different Cathode Potentials

[0041] Example 2 After the current of the microbial electrolytic cell reaches stability, the electrochemical workstation is used for cyclic voltammetry scanning analysis. The potential range of the scanning is -1.0~1.0V, and the rate is 1mV s -1 .

[0042] Under the same conditions, the catholyte without activated sludge and sodium 2-bromoethanesulfonate is used as a contrast, i.e. blank carbon cloth, and other operations are the same as in Example 1.

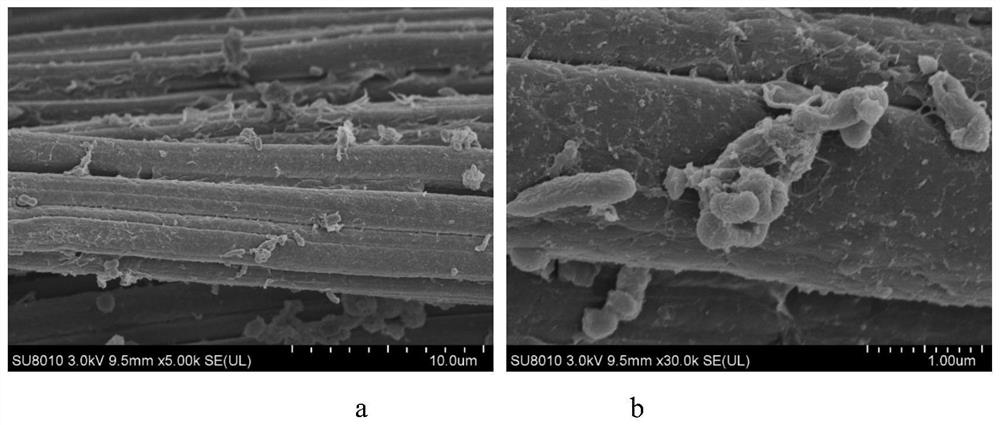

[0043] Such as Figure 5 As shown, when the blank carbon cloth was used as the cathode, no redox peak was detected, which indicated the lack of participation of electron mediators in the process. Compared with the control group, the response of the cathodic current in the cyclic voltammetry curve of the experimental group is higher than that of the control group in the scanning range, and the current range is about -0.04~0.08A (-0.6V), -0.017~0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| ion source temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com