Pin-free and welding-free SMD (Surface Mount Device) electronic component

A kind of technology of electronic components and patch type, which is applied in the direction of adding resistors, electrical components, electrical components, etc. at the lead-out end, which can solve the problems of poor anti-combination wave capability, small flow rate, and complicated production, so as to improve the current flow rate , Increase the effective area and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

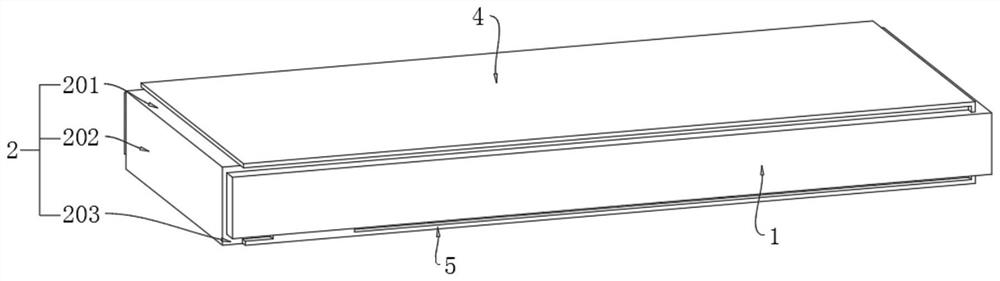

[0029] as attached figure 1 to attach image 3 Shown:

[0030] The present invention provides a chip-type electronic component without pins and soldering, comprising a substrate 1; an upper electrode surface 2 is arranged on the top of the substrate 1; the upper electrode surface 2 consists of an upper electrode layer 201, an auxiliary electrode layer 202 and The upper bonding electrode 203 is composed; the bottom of the substrate 1 is provided with a lower electrode surface 3; the lower electrode surface 3 is composed of a lower electrode layer 301 and a lower bonding electrode 302; the top of the upper electrode surface 2 is covered with an upper insulating layer 4; The bottom of the lower electrode surface 3 is covered with a lower insulating layer 5 ; an isolation gap 6 is provided between the upper bonding electrode 203 and the lower electrode layer 301 .

[0031] Wherein, the substrate 1 is a piezoresistor, and the upper electrode surface 201 , the upper bonding electr...

Embodiment 2

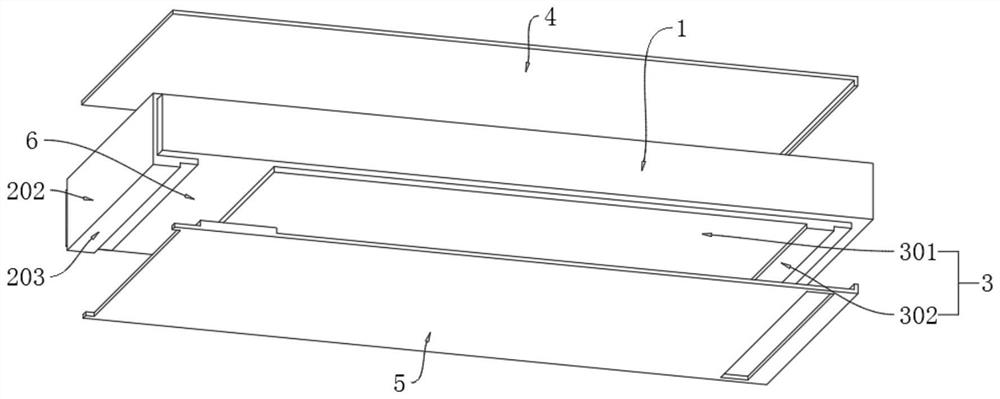

[0040] as attached Figure 4 to attach Figure 5 Shown:

[0041] The present invention provides a chip-type electronic component without pins and soldering, comprising a substrate 1; an upper electrode surface 2 is arranged on the top of the substrate 1; the upper electrode surface 2 consists of an upper electrode layer 201, an auxiliary electrode layer 202 and The upper bonding electrode 203 is composed; the bottom of the substrate 1 is provided with a lower electrode surface 3; the lower electrode surface 3 is composed of a lower electrode layer 301 and a lower bonding electrode 302; the top of the upper electrode surface 2 is covered with an upper insulating layer 4; The bottom of the lower electrode surface 3 is covered with a lower insulating layer 5 ; an isolation gap 6 is provided between the upper bonding electrode 203 and the lower electrode layer 301 .

[0042] Wherein, the substrate 1 is a positive temperature coefficient thermistor, and the upper electrode surfac...

Embodiment 3

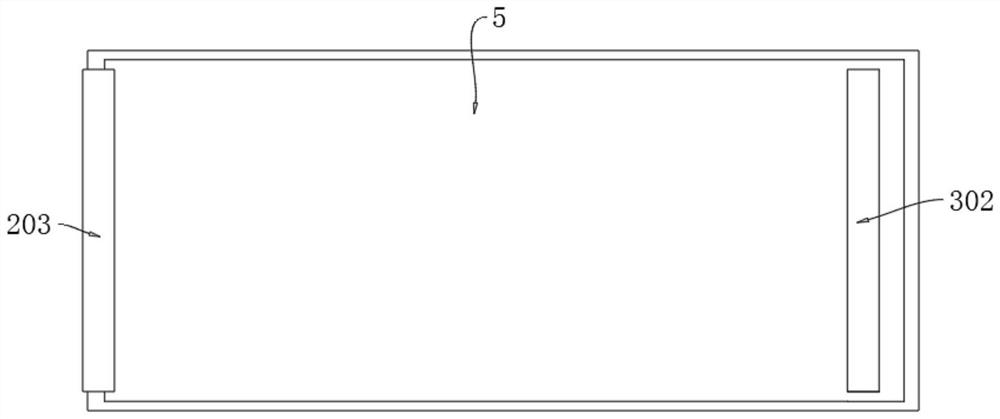

[0050] as attached Image 6 Shown:

[0051] The present invention provides a chip-type electronic component without pins and soldering, comprising a substrate 1; an upper electrode surface 2 is arranged on the top of the substrate 1; the upper electrode surface 2 consists of an upper electrode layer 201, an auxiliary electrode layer 202 and The upper bonding electrode 203 is composed; the bottom of the substrate 1 is provided with a lower electrode surface 3; the lower electrode surface 3 is composed of a lower electrode layer 301 and a lower bonding electrode 302; the top of the upper electrode surface 2 is covered with an upper insulating layer 4; The bottom of the lower electrode surface 3 is covered with a lower insulating layer 5 ; an isolation gap 6 is provided between the upper bonding electrode 203 and the lower electrode layer 301 .

[0052] Wherein, the substrate 1 is a piezoresistor, and the upper electrode surfaces 201, 203 and the lower electrode surface 3 are el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com