Formula and preparation method of antibiotic-free creep feed for weaned piglets

A technology for weaned piglets and creep feed, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve problems such as weaning stress, toxin removal, and piglet illness, and achieve weight gain and stable blood sugar Concentration, effect of reducing starvation stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

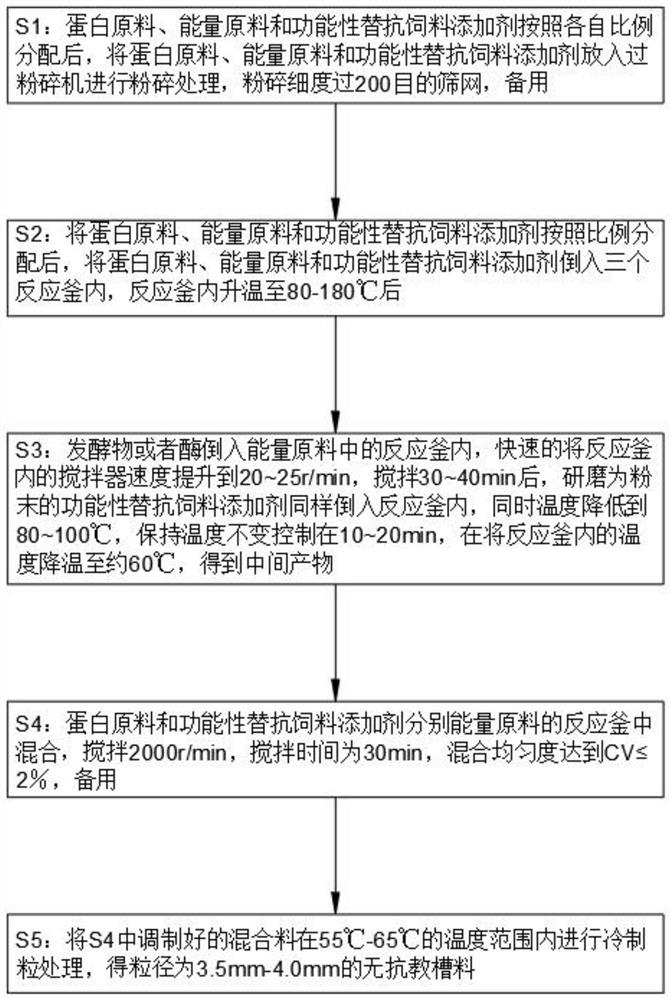

Method used

Image

Examples

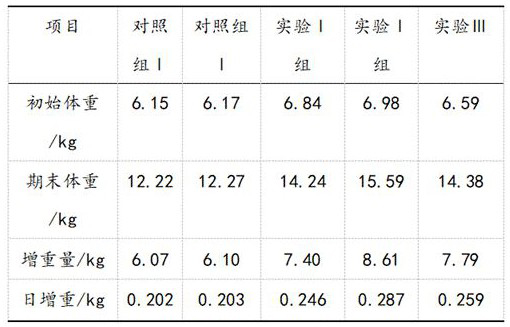

Embodiment 1

[0038] 120 parts of protein raw materials, 170 parts of energy raw materials and 110 parts of functional antibiotic feed additives;

[0039] One portion of the protein raw material includes: 34 parts of fermented soybean meal, 10 parts of soybean meal with a protein mass fraction of 40%, 7 parts of puffed full-fat soybean, 2 parts of fish meal, 7 parts of potato protein powder and 15 parts of wheat hydrolyzed protein;

[0040] One serving of energy raw materials includes: 39 parts of common corn, 22 parts of puffed corn, 14 parts of micronized rice, 3 parts of yeast hydrolyzate, 2 parts of butyric acid bacteria, 2 parts of Bacillus subtilis, 6 parts of glucose, 2 parts of calcium dihydrogen phosphate, 6 parts of lysine, 4 parts of Aicanbao, 3 parts of calcium formate, 1 part of methionine, 1 part of emulsified oil, 2 parts of lactobacillus lactobacillus;

[0041] One serving of the functional antibiotic feed additive includes: 4 parts of antibacterial peptides, 1-2 parts of pl...

Embodiment 2

[0043]135 parts of protein raw materials, 180 parts of energy raw materials and 120 parts of functional antibiotic feed additives;

[0044] One portion of the protein raw material includes: 37 parts of fermented soybean meal, 20 parts of soybean meal with a protein mass fraction of 40%, 7.5 parts of puffed full-fat soybean, 5 parts of fish meal, 8 parts of potato protein powder and 20 parts of wheat hydrolyzed protein;

[0045] One serving of energy raw materials includes: 41 parts of common corn, 24 parts of puffed corn, 15 parts of micronized rice, 5 parts of yeast hydrolyzate, 3 parts of butyric acid bacteria, 3 parts of Bacillus subtilis, 8 parts of glucose, 3 parts of calcium dihydrogen phosphate, 8 parts of lysine, 5 parts of Aicanbao, 4 parts of calcium formate, 2 parts of methionine, 2 parts of emulsified oil, 6 parts of lactobacillus lactobacillus;

[0046] One serving of the functional antibiotic feed additive includes: 5 parts of antimicrobial peptides, 1.5 parts of...

Embodiment 3

[0048] 150 parts of protein raw materials, 190 parts of energy raw materials and 130 parts of functional antibiotic feed additives;

[0049] One portion of the protein raw material includes: 40 parts of fermented soybean meal, 30 parts of soybean meal with a protein mass fraction of 40%, 8 parts of puffed full-fat soybean, 7 parts of fish meal, 9 parts of potato protein powder and 25 parts of wheat hydrolyzed protein;

[0050] One serving of energy raw materials includes: 43 parts of common corn, 26 parts of puffed corn, 17 parts of micronized rice, 8 parts of yeast hydrolyzate, 5 parts of butyric acid bacteria, 5 parts of Bacillus subtilis, 9 parts of glucose, 5 parts of calcium dihydrogen phosphate, 9 parts of lysine, 6 parts of Aicanbao, 5 parts of calcium formate, 3 parts of methionine, 1-3 parts of emulsified oil, 8 parts of lactobacillus lactobacillus;

[0051] One serving of the functional antibiotic feed additive includes: 6 parts of antimicrobial peptide, 2 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com