VOCs waste gas treatment device and method

A waste gas treatment device and gas technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as discomfort, special odor, toxicity, irritation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

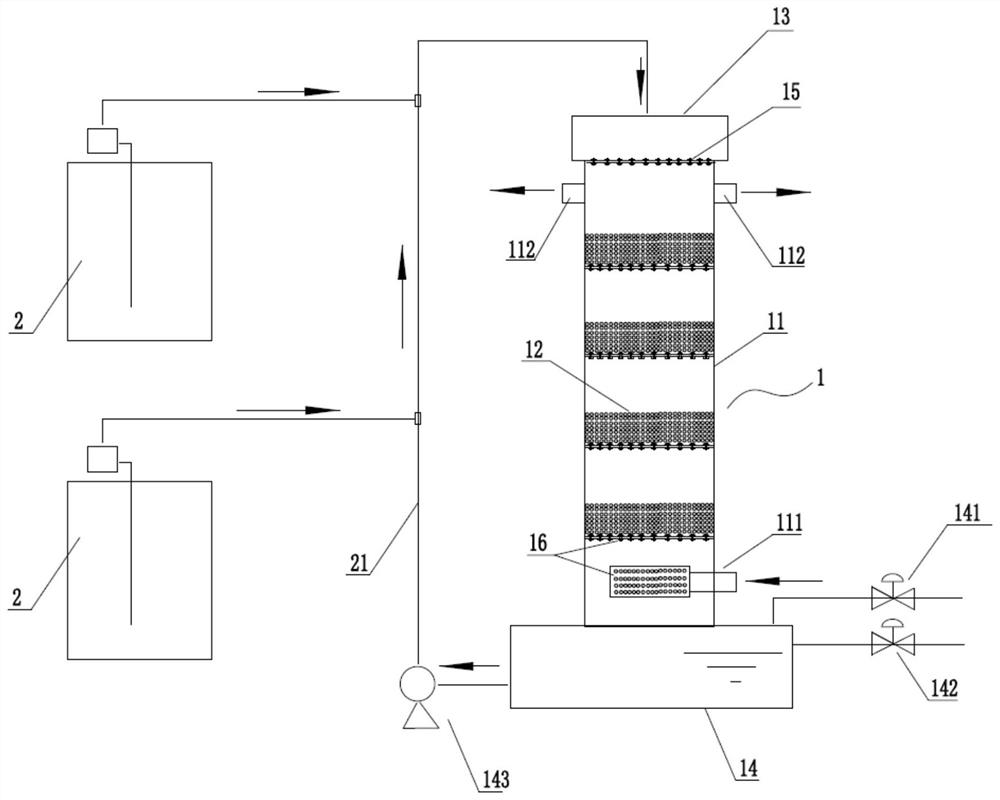

[0051] First, the spray flow rate should not be too large to ensure that the catalyst particles are wet. Moreover, there is no water or a small amount of water in the catalyst layer, so that the bottom-up exhaust gas can be absorbed by the spray water containing a certain concentration of oxidizing agents, and the part that cannot be absorbed by the spray water is absorbed by the catalyst particles. The organic matter and oxidizing agent are degraded under the action of the catalyst to achieve the purpose of removing the organic matter in the exhaust gas.

[0052] The exhaust gas is passed into the air inlet 111 of the reaction tower 1 from bottom to top according to the speed V0≤10m / h, and the exhaust gas pressure should not be too high to ensure that the exhaust gas overcomes the resistance to discharge pressure.

[0053] The oxidizing agent is added to the outlet of the circulating pump 143 in a certain proportion through the dosing device 2 . The specific address can be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com