Progressive magnetic pulse forming method and device for thin-wall metal annular shell part

A magnetic pulse forming and annular shell technology, applied in the field of forming large thin-walled metal annular shell parts, can solve the problems of insufficient energy utilization, low energy utilization, insufficient equipment energy, etc., and achieve easy replacement and reduce friction effects. , the effect of high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

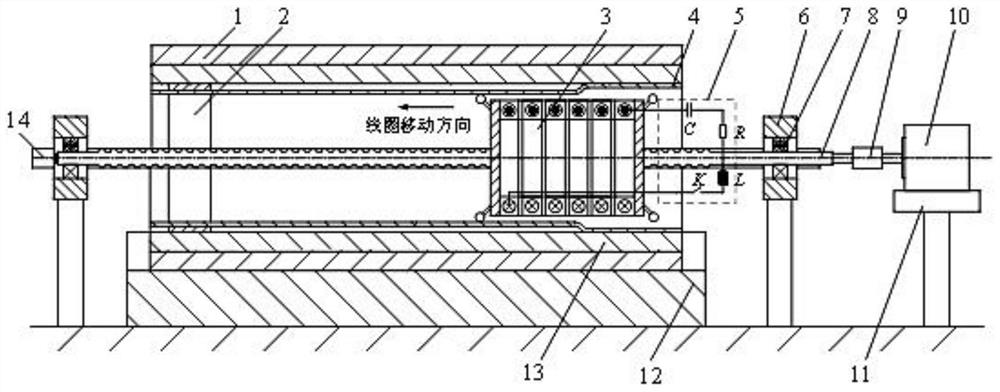

[0047] Such as Figure 1-4 As shown, this embodiment provides a progressive magnetic pulse forming method and device for a thin-walled metal annular shell. Specifically, in this embodiment, the electromagnetic bulging support assembly plastic of the rolled and welded aluminum cylinder is used as an example to describe in detail:

[0048]The thin-walled metal annular shell 4 used in this embodiment is an AA5754 aluminum alloy welding drum, and its structural size is 250mm (outer diameter) × 1mm (wall thickness) × 1500mm (length). The material of the assembled structure to be supported is plastic , the structural size of the assembled plastic pipe is 300 (outer diameter) × 45mm (wall thickness) × 1500mm (length); the material of mold 1 is 45# steel, and the structural size is 300 (inner diameter) × 50mm (wall thickness) × 1500mm ( length), the forming coil is wound by a copper wire 304 with a rectangular cross section of 5mm×7mm, with a total of 20 turns, the outer diameter is 2...

Embodiment 2

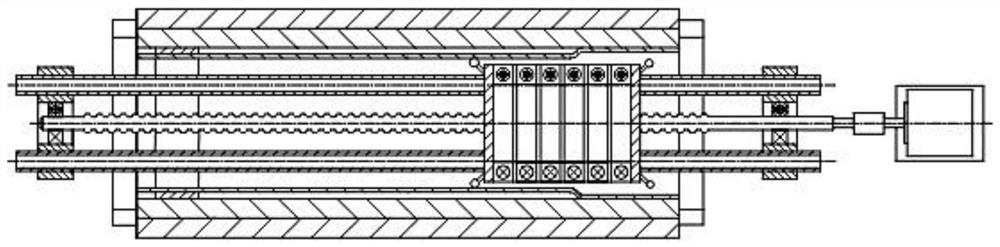

[0071] This embodiment is improved on the basis of Embodiment 1, the improvements are as follows: Figure 5-Figure 7 As mentioned above, this embodiment takes the electromagnetic shrinking and shaping of the rolled and welded aluminum cylinder as an example for illustration:

[0072] The thin-walled metal annular shell 4 used in this embodiment is an AA5754 aluminum alloy welding cylinder, and its structural size is 250mm (inner diameter) × 1.5mm (wall thickness) × 1000mm (length); the forming mold material is 45# steel, and the structure The size is 245mm (radius) × 1000mm (length); the forming coil is wound by a copper wire with a rectangular cross section of 5mm × 7mm, with a total of 15 turns, the inner diameter is 255mm, and the effective length of the forming coil working area is about 105mm (L).

[0073] In this embodiment, the diameter of the above-mentioned rolled and welded aluminum cylinder is reduced to the outer surface of the mold to achieve the purpose of shapin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com