Electric power equipment metal mold casting combined mold

A technology for metal mold casting and electrical equipment, which is applied in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as the shape or fineness of the mold core, and achieve difficult transformation, save expensive materials, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

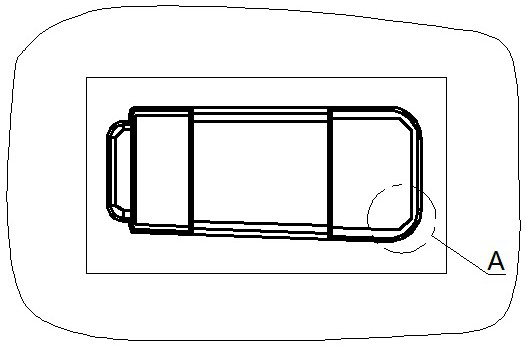

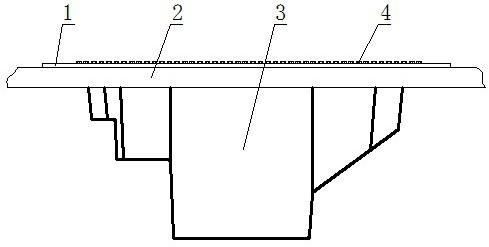

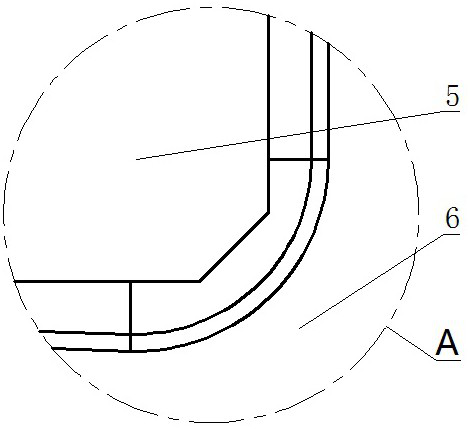

Image

Examples

Embodiment Construction

[0026] As shown in the figure, its preferred embodiment is: the movable interconnection mechanism 7 is all established around the mold column assembly 12, and the mold column assembly 12 can be directly and flexibly connected around, and the top of the mold column assembly 12 is provided with a nut column 13 , the nut column 13 is fixed on the top of the mold column assembly 12 .

[0027] The bolt 4 is screwed into the screw hole 14 of the positioning plate 1, and then screwed into the nut column 13 of the mold column assembly 12 after passing through the screw hole 14. Among them, the independent positioning of the bolt 4 and the height positioning of the mold column assembly 12 are realized, and the height of the mold column assembly 12 can be adjusted with high precision only by rotating the bolt 4 .

[0028] The mold column assembly 12 is composed of mold column units of various lengths to form mold column assemblies 12 of various lengths, which are arranged on the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com