Preparation method of carbon fiber reinforced terpolymer alloy

A terpolymer and butadiene terpolymer technology, applied in the field of engineering plastics, can solve the problems of high air humidity dependence of timbre, large difference in wood silver color, long growth cycle, etc., and achieve excellent timbre and low shrinkage The effect of strong rate and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

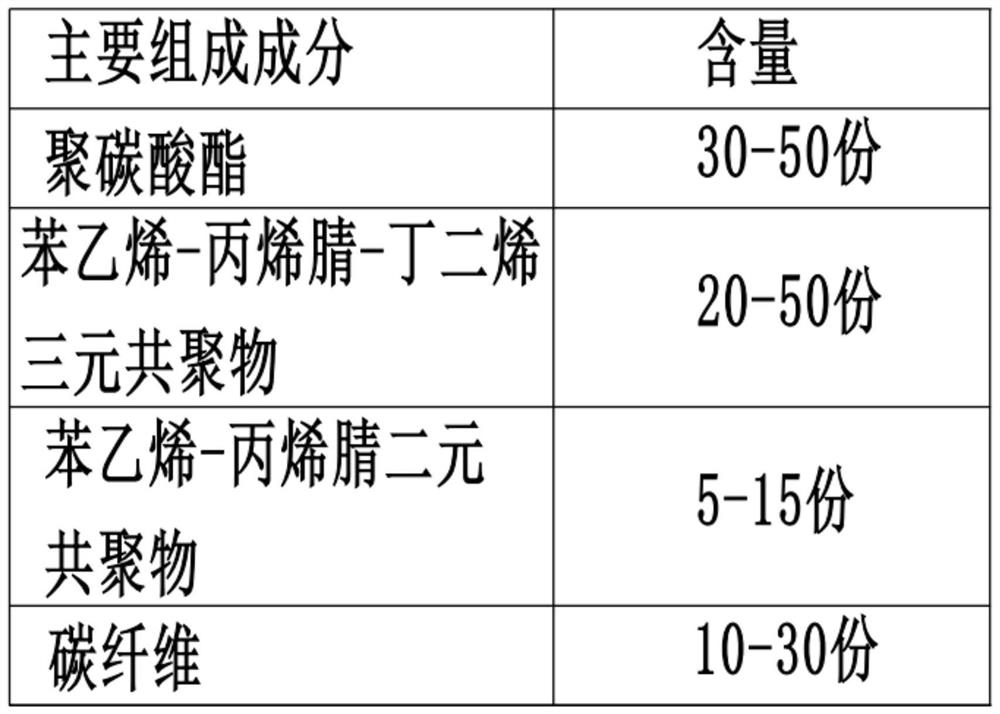

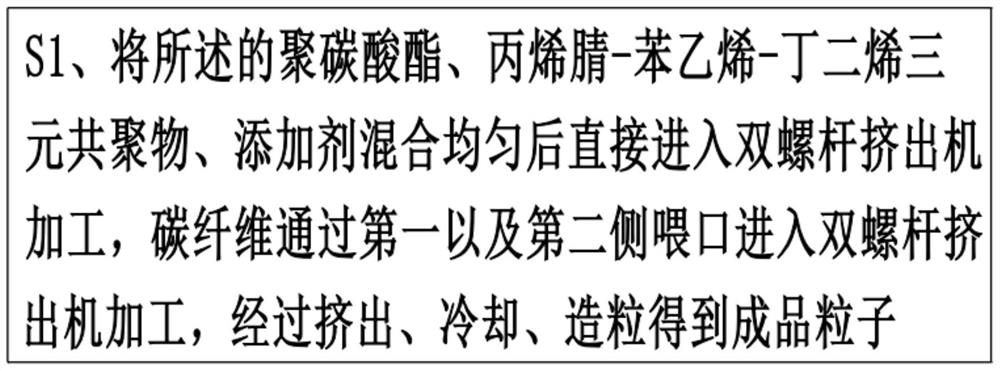

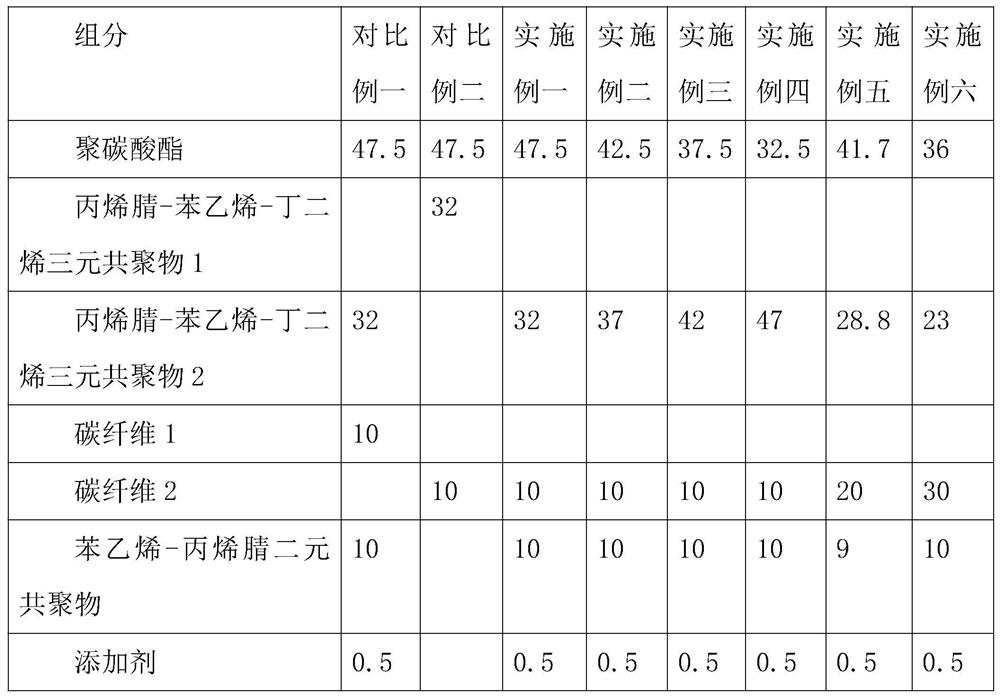

[0032] The present invention provides a kind of carbon fiber reinforced terpolymer alloy preparation method here by improving, as Figure 1-Figure 4 shown, including the following components:

[0033] 47.5 parts of polycarbonate;

[0034] 32 parts of styrene-acrylonitrile-butadiene terpolymer;

[0035] 10 parts of styrene-acrylonitrile binary copolymer;

[0036] 10 parts carbon fiber.

[0037] Further, the melt flow rate of polycarbonate resin is 20g / 10min (300 ℃, 1.2kg), and acrylonitrile-styrene-butadiene terpolymer is preferred, and butadiene content is 30%, and flow improves The additive is acrylonitrile-styrene binary copolymer, the melt flow rate is 40g / 10min (190°C, 5kg), the number average molecular weight of 10 parts of styrene-acrylonitrile binary copolymer is 17000g / mol, and the carbon fiber The diameter is 7 μm, preferably, the tensile modulus of carbon fiber=295GPa, tensile strength=4.9GPa, carbon fiber reinforced polycarbonate / acrylonitrile-styrene-butadiene ...

Embodiment 2

[0041] A method for preparing a carbon fiber reinforced terpolymer alloy, comprising the following components:

[0042] 42.5 parts of polycarbonate;

[0043] 37 parts of styrene-acrylonitrile-butadiene terpolymer;

[0044] 10 parts of styrene-acrylonitrile binary copolymer;

[0045] 10 parts carbon fiber.

[0046] Further, the melt flow rate of polycarbonate resin is 20g / 10min (300 ℃, 1.2kg), and acrylonitrile-styrene-butadiene terpolymer is preferred, and butadiene content is 30%, and flow improves The additive is acrylonitrile-styrene binary copolymer, the melt flow rate is 40g / 10min (190°C, 5kg), the number average molecular weight of 10 parts of styrene-acrylonitrile binary copolymer is 17000g / mol, and the carbon fiber The diameter is 7 μm, preferably, the tensile modulus of carbon fiber=295GPa, tensile strength=4.9GPa, carbon fiber reinforced polycarbonate / acrylonitrile-styrene-butadiene terpolymer alloy material, can also add 0.5 parts Additives, including antioxidan...

Embodiment 3

[0050] A method for preparing a carbon fiber reinforced terpolymer alloy, comprising the following components:

[0051] 37.5 parts of polycarbonate;

[0052] 42 parts of styrene-acrylonitrile-butadiene terpolymer;

[0053] 10 parts of styrene-acrylonitrile binary copolymer;

[0054] 10 parts carbon fiber.

[0055]Further, the melt flow rate of polycarbonate resin is 20g / 10min (300 ℃, 1.2kg), and acrylonitrile-styrene-butadiene terpolymer is preferred, and butadiene content is 30%, and flow improves The additive is acrylonitrile-styrene binary copolymer, the melt flow rate is 40g / 10min (190°C, 5kg), the number average molecular weight of 10 parts of styrene-acrylonitrile binary copolymer is 17000g / mol, and the carbon fiber The diameter is 7 μm, preferably, the tensile modulus of carbon fiber=295GPa, tensile strength=4.9GPa, carbon fiber reinforced polycarbonate / acrylonitrile-styrene-butadiene terpolymer alloy material, can also add 0.5 parts Additives, including antioxidant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com