Metal anticorrosive material

A metal anti-corrosion and photoelectrode technology, applied in nanotechnology, manganese compounds, cobalt compounds, etc. for materials and surface science, can solve the problems of high carrier recombination rate, limited visible light absorption, limited production and application, etc., to achieve Reduce recombination rate, significant protective effect, and promote the effect of photogenerated charge separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

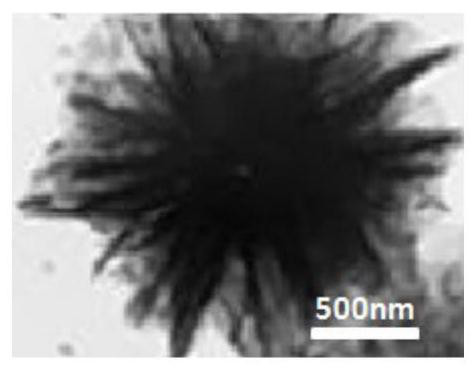

[0014] (1) Add 5mmol of cobalt nitrate and 5mmol of molybdenum nitrate to 30ml of glycerol, then add dodecyl mercaptan and urea, and mix well by ultrasonic. The mass ratio of cobalt nitrate, dodecyl mercaptan and urea is 1:0.3 : 0.3; transferred to the autoclave, reacted for 10h at 180 degrees Celsius to obtain flower-like CoMoO 4 ; (2) the flower-like CoMoO 4 Dissolve in 40ml of deionized water, add 1mmol of ferric nitrate, 1mmol of manganese nitrate and 0.8mmol of NH 4 F. Transfer to a high-pressure reactor and continue to react at 180 degrees Celsius for 10 hours; heat the obtained product at 300 degrees Celsius to obtain flower-shaped CoMoO 4 loaded with nano-FeMnO 3 Granular composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com