Photoelectrochemical anti-corrosion protection composite photo-anode and preparation method and application of photoelectrochemical anti-corrosion protection composite photo-anode

A photoelectrochemical and composite light technology, applied in the field of metal anti-corrosion, can solve the problems of limited application and development of photocatalytic materials, high carrier recombination rate, and can only function under light, so as to achieve high-efficiency photoelectrochemical cathodic protection, improve Photoelectric properties, the effect of reducing the carrier recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Co(OH) 2 / WO 3 Modified TiO 2 Preparation of composite photoanode:

[0047] 1) Preparation of TiO by anodic oxidation 2 For the nanotube sample, take out the Ti sheet from the absolute ethanol solution, dry it and connect it to the anode of the DC power supply, and the platinum sheet as the cathode, apply a potential in the electrolyte for anodic oxidation, and use a muffle furnace to test the material at 500 °C heat treatment to obtain TiO 2 nanotube film;

[0048] 2), using an electrochemical workstation, the TiO prepared in step (1) 2 As the working electrode, the platinum sheet and the SCE are respectively the counter electrode and the reference electrode, deposited at a constant -0.5V for 80s. The electrolyte is 5mmol / L Na 2 WO 4 2H 2 O and 15mmol / L H 2 o 2 The mixed solution was adjusted to pH 1.5 with concentrated nitric acid. After electrodeposition, the sample was washed with deionized water and dried, and calcined in a muffle furnace at 500 °C for ...

Embodiment 2

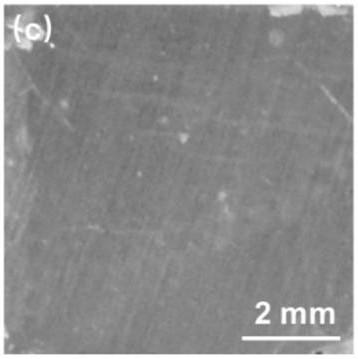

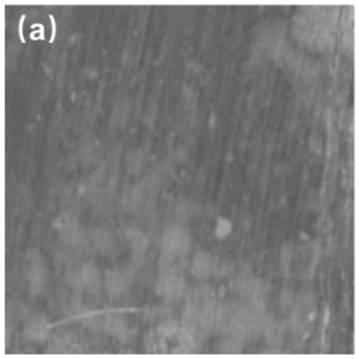

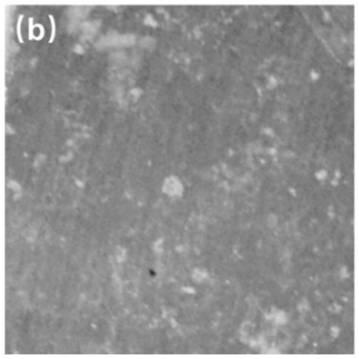

[0055] 1), use conductive glue to unmodify TiO 2 One end of the photoanode material is connected to the copper wire as the research electrode, and the other end is connected to the aluminum alloy. The coupling electrode composed of the two is used as the working electrode, the platinum sheet is used as the counter electrode, and the SCE is used as the reference electrode. The electrolyte is 3.5% NaCl solution ; Use the electrochemical workstation to test the change curve of the open circuit potential (OCP) with time under light and dark conditions, and study its photochemical protection performance on the metal auxiliary electrode;

[0056] 2) Use the noise (EN) module of the electrochemical workstation to test and study the change of the photogenerated current density generated by the electrode under light and dark conditions with time;

[0057] 3), through the copper wire TiO 2 Connect the photoanode to the aluminum alloy, place it in 3.5% NaCl solution, and use 12h light / 1...

Embodiment 3

[0059] 1), use conductive glue to make WO 3 Modified TiO 2One end of the photoanode material is connected to the copper wire as the research electrode, and the other end is connected to the aluminum alloy. The coupling electrode composed of the two is used as the working electrode, the platinum sheet is used as the counter electrode, and the SCE is used as the reference electrode. The electrolyte is 3.5% NaCl solution ; Use the electrochemical workstation to test the change curve of the open circuit potential (OCP) with time under light and dark conditions, and study its photochemical protection performance on the metal auxiliary electrode;

[0060] 2) Use the noise (EN) module of the electrochemical workstation to test and study the change of the photogenerated current density generated by the electrode under light and dark conditions with time;

[0061] 3), through the copper wire to WO 3 Modified TiO 2 Connect the photoanode to the aluminum alloy, place it in 3.5% NaCl s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com