PCB methanesulfonic acid tin stripping waste liquid cyclic regeneration method and application thereof

A technology of waste liquid recycling and methanesulfonic acid, which is applied in photography technology, instruments, photography auxiliary technology and other directions, can solve problems that have not been studied before, and achieve the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

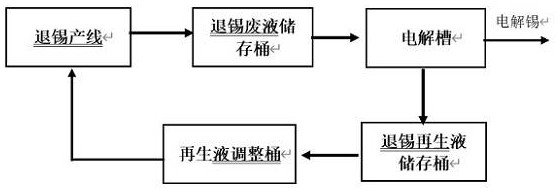

Image

Examples

Embodiment 1

[0036] Each composition of the tin methanesulfonate stripping liquid of embodiment one is as follows:

[0037] component name methanesulfonic acid Stannous methanesulfonate nitric acid EDTA-2Na Benzotriazole magnesium sulfate percentage content 15% 2% 1.5% 0.5% 0.5% 0%

[0038] Correspondingly, the preparation method of tin stripping solution is as follows:

[0039] 1.1 According to the components and contents of the above tin stripping solution, sequentially weigh methanesulfonic acid and stannous methanesulfonate and add them to the measured pure water, stir and dissolve with a glass rod to obtain a mixed solution;

[0040] 1.2 The solution obtained by the above mixture is stirred, and the weighed nitric acid, magnesium sulfate, EDTA-2Na and benzotriazole are added in sequence according to the above concentrations. After completely mixing and dissolving, add water to the mark, and then stir to obtain methyl Sulfonic acid tin stripping so...

Embodiment 2

[0042] The components of the tin methanesulfonate stripping solution of embodiment two are as follows:

[0043] component name methanesulfonic acid Stannous methanesulfonate nitric acid EDTA-2Na Benzotriazole magnesium sulfate percentage content 15% 5% 0% 1% 1% 2%

[0044] Correspondingly, the preparation method of tin stripping solution is as follows:

[0045] 2.1 According to the components and contents of the above tin stripping solution, sequentially weigh methanesulfonic acid and stannous methanesulfonate and add them to the measured pure water, stir and dissolve with a glass rod to obtain a mixed solution;

[0046] 2.2 The solution obtained from the above mixture is stirred, and the weighed nitric acid, magnesium sulfate, EDTA-2Na and benzotriazole are added in sequence according to the above concentrations. After completely mixing and dissolving, add water to the mark, and then stir to obtain methyl Sulfonic acid tin stripping solut...

Embodiment 3

[0048] The components of the tin methanesulfonate stripping solution of embodiment three are as follows:

[0049] component name methanesulfonic acid Stannous methanesulfonate sulfuric acid EDTA-2Na Tolylbenzotriazole magnesium sulfate ammonium sulfate percentage content 20% 0.5% 1.5% 2% 0.5% 1% 1%

[0050] The corresponding preparation method of tin stripping solution is as follows:

[0051] 3.1 According to the components and contents of the above tin stripping solution, sequentially weigh methanesulfonic acid and stannous methanesulfonate and add them to the measured pure water, stir and dissolve with a glass rod to obtain a mixed solution;

[0052] 3.2 The solution obtained by the above mixture is stirred, and the weighed sulfuric acid, magnesium sulfate, ammonium sulfate, EDTA-2Na and benzotriazole are added in sequence according to the above concentrations, and after complete mixing and dissolution, add water to the scale, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com