Strong weathered mudstone deep cutting slope protection structure and construction method

A technology for slope protection and strong weathering, which is used in infrastructure engineering, underwater structures, excavation, etc., can solve the problems of easy corrosion of hinged structures, lack of supporting effect, and difficult processing, and achieves high efficiency. Promote application value, ease of processing and installation, and the effect of reducing evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

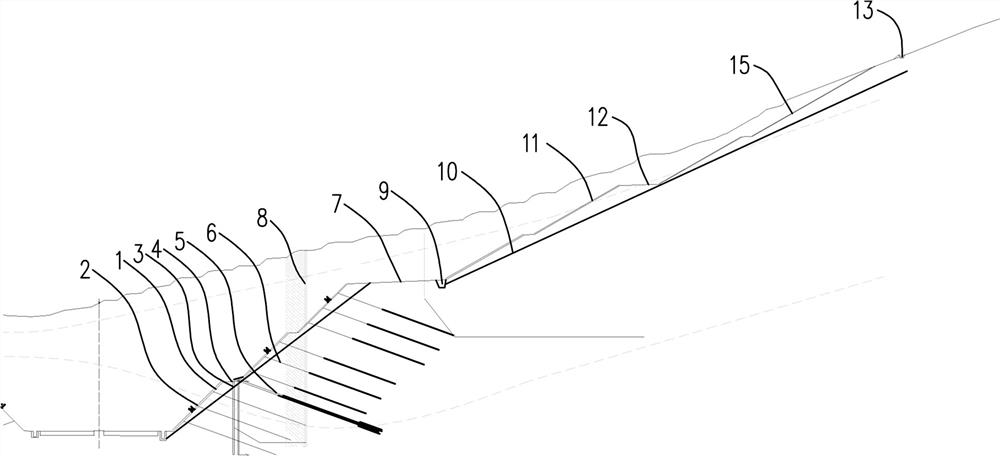

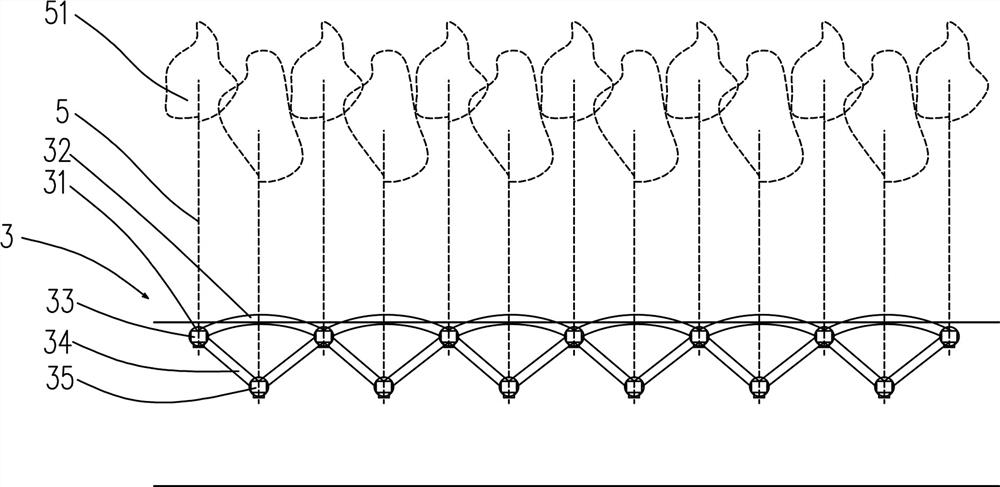

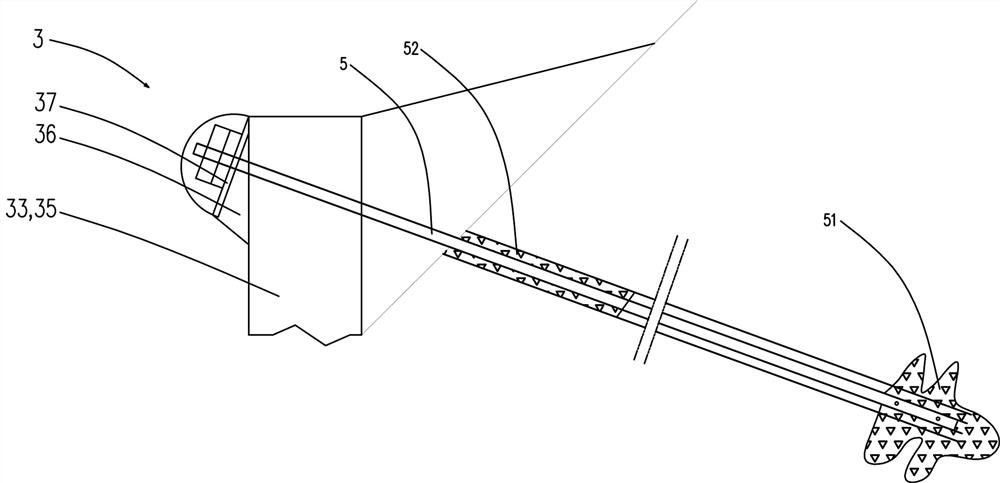

[0042] Such as figure 1Among them, a strong weathered mudstone deep cutting slope protection structure includes a multi-level steep slope protection 1 at the bottom and a multi-level gentle slope protection 15 at the top. The steep slope protection 1 in this example refers to a slope protection with a slope ratio of 1:1 structure. Gentle slope protection 15 refers to a slope protection structure with a slope ratio of less than 1:1.25. The preferred gentle slope protection 15 slope ratio in this example is 1:1.75. The steep slope protection 1 in this example is three grades, and the vertical height of each grade is not more than 10 meters, and the remaining ones are gentle slope protection 15, which are divided into four grades.

[0043] A platform is provided between the steep slope protection 1 at all levels, a platform is provided between the gentle slope protection 15 at all levels, a boundary platform 7 is provided between the steep slope protection 1 and the gentle slop...

Embodiment 2

[0057] A construction method of the above-mentioned strong weathered mudstone deep cutting slope protection structure, comprising the following steps:

[0058] S1, such as figure 1 Among them, excavate from the top, and construct the top drainage ditch 13 after excavation; the bottom of the top drainage ditch 13 is provided with a waterproof geotextile, and the top drainage ditch 13 is connected with the rapid flow channel, which is not shown in the figure.

[0059] S2, such as Figure 7 Among them, after excavating the first-level gentle slope protection 15, the grooves for the embedded seepage pipes 10 are excavated, including the pipe grooves for the longitudinal seepage pipes 102 and the horizontal seepage pipes 101. The horizontal seepage pipes 101 are more difficult to construct. Special equipment is set to construct the horizontal pipe groove 103, the depth of the horizontal pipe groove 103 is 30cm, the width is 2cm, the diameter of the horizontal seepage pipe 101 is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com