Phase change heat storage and heat pump heat source coupled heavy oil well heating system and control method

A phase change heat storage and heating system technology, applied in the field of heavy oil well heating, can solve the problems of increased production cost, low heat supply, low heat conversion rate, etc., to ensure continuous operation, high heating timeliness, and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

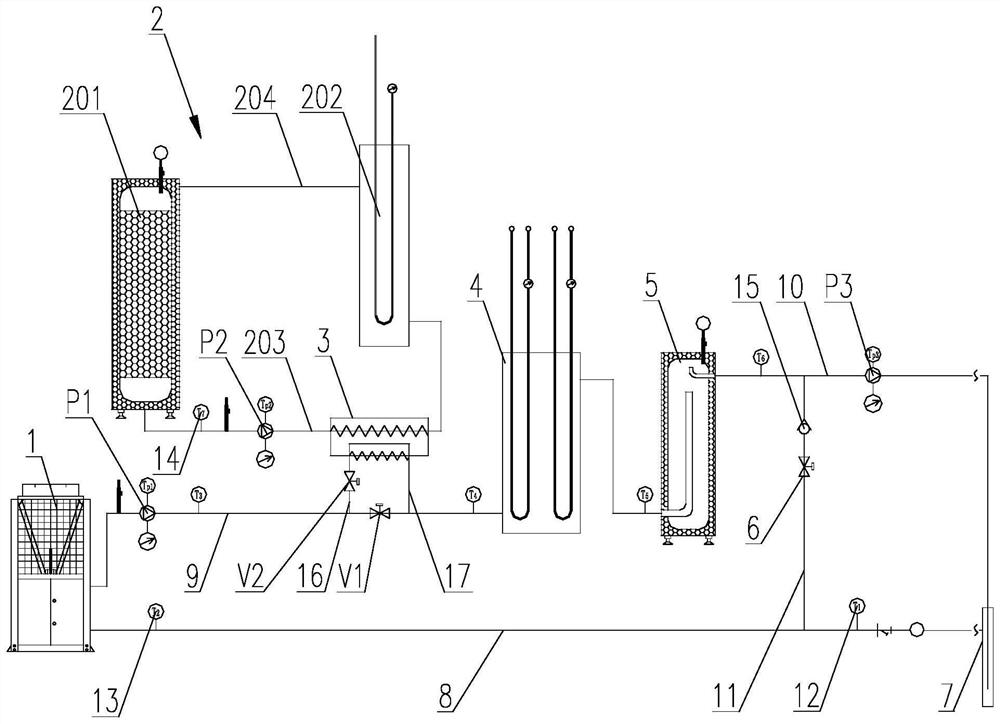

[0053] like figure 1 As shown, a heavy oil well heating system coupled with phase change heat storage and heat pump heat source, including air source heat pump 1, phase change energy storage system 2, heat exchanger 3, backup electric heating device 4, buffer tank 5 and water mixing valve 6. Heat exchanger 3 adopts plate heat exchanger, standby electric heating device 4 adopts pipeline electric heater, air source heat pump 1 adopts cascade air source heat pump, rated outlet water temperature: 75°C, maximum outlet water temperature: 85°C ;

[0054] The water inlet of the air source heat pump 1 communicates with the water outlet of the downhole hot water circulation unit 7 through the liquid inlet pipe 8. The downhole hot water circulation unit 7 includes a hollow sucker rod and a Y-shaped filter. For example, the water outlet of the hollow sucker rod passes through The Y-shaped filter is connected with the liquid inlet pipe 8, and the liquid inlet pipe 8 is connected with the ...

Embodiment 2

[0065] The present invention also provides a control method based on the phase change thermal storage and heat pump heat source coupled heavy oil well heating system, including a first control method and a second control method using independent control strategies, the first control method is used to control phase Whether the variable energy storage system 2 or / and the standby electric heating device 4 is combined with the air source heat pump 1 for heat supply, and the second control method is used to control whether the electric heating device 202 of the energy storage system is working;

[0066] Described first control method comprises the following steps:

[0067] Step s1, set T in the controller in Set value for the outlet water temperature of the downhole hot water circulation unit 7, for example, T in The factory setting is 55°C, adjustable;

[0068] Step s2, start the air source heat pump 1, the first circulating pump P1 and the third circulating pump P3, and open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com