Thermoelectric cooperation system integrated with steam ejector and operation method

A thermoelectric synergy and injector technology, which is applied to steam engine devices, machines/engines, engine components, etc., can solve problems such as low energy utilization efficiency, influence of power generation output, and large investment in absorption heat pumps, and achieve high energy utilization efficiency and security Heating load and flexible adjustment of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

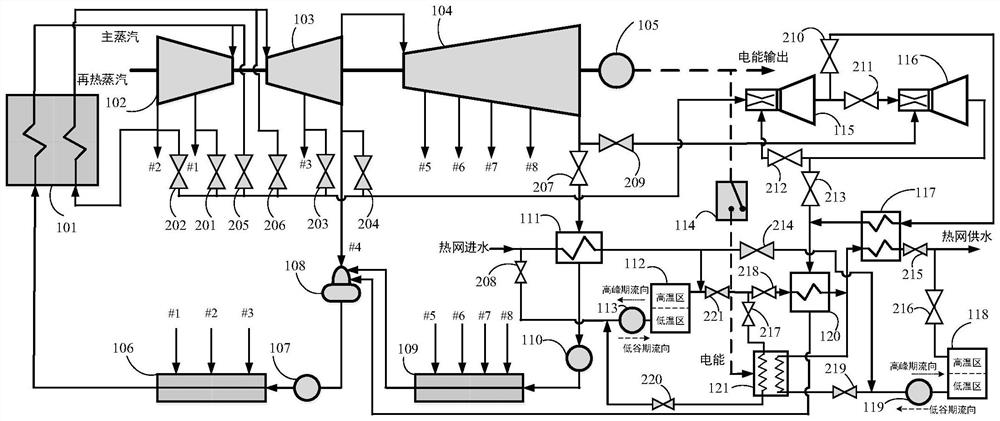

[0018] In order to realize cascaded utilization of energy, the temperature of the heat source and the heated fluid should be reasonably matched in the heat exchange process. For this reason, the present invention adopts the technical scheme of two-stage steam injector cascade ejection steam turbine exhaust to obtain two different types of medium and low pressure. The steam with different parameters can utilize heat energy of different grades in an orderly manner during the heat exchange process. Such as figure 1As shown, a thermoelectric synergy system integrating steam injectors in the present invention includes the main steam side of the boiler 101, the high-pressure cylinder 102 of the steam turbine, the reheat steam side of the boiler 101, the medium-pressure cylinder 103 of the steam turbine, the low-pressure cylinder 104 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com