High-temperature and high-pressure double-pipe heat exchanger

A high-temperature, high-pressure, sleeve-type technology, applied in the field of heat exchange, can solve the problems of high processing cost, immature process, and low processing efficiency, and achieve reduced processing difficulty and cost, absolutely uniform flow distribution, and no drop in heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

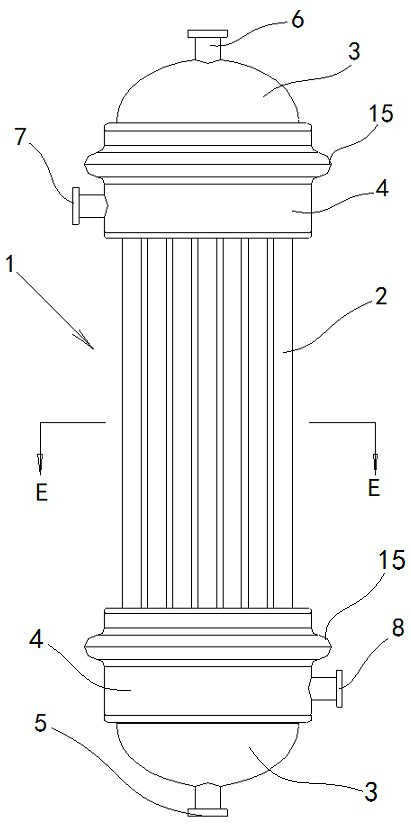

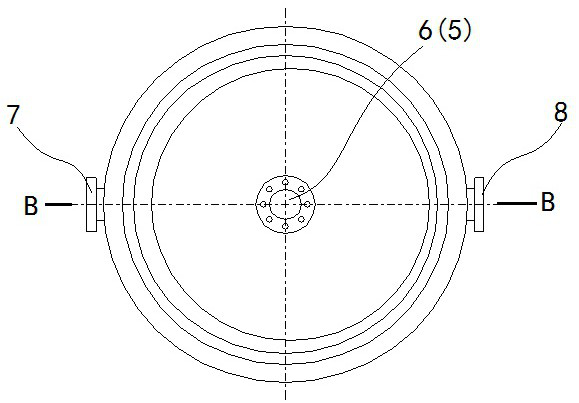

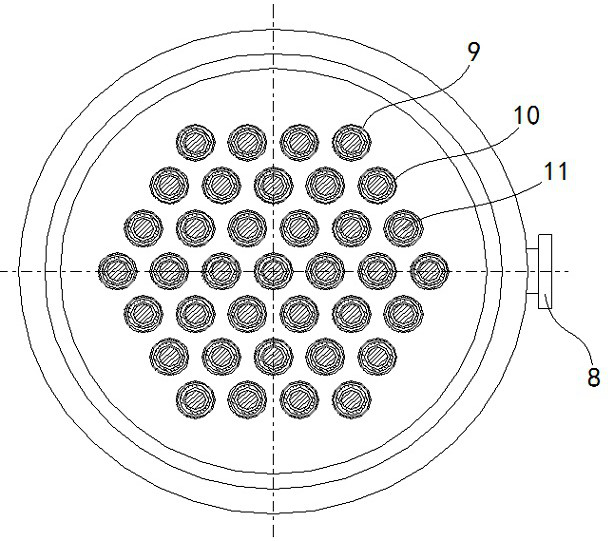

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7As shown, a high-temperature and high-pressure casing heat exchanger includes a heat exchanger body 1, and the heat exchanger body 1 is composed of several sets of casing heat exchange tubes 2, a first medium pipe box 3, and a second medium pipe box 4 components, the first medium tube box 3 and the second medium tube box 4 are respectively arranged at both ends of the sleeve-type heat exchange tube 2, and the first medium tube box 3 is at the outermost end; wherein, in the heat exchange The first medium pipe box 3 at one end of the heat exchanger body 1 is provided with a first medium outlet 6, and the second medium pipe box 4 is provided with a second medium inlet 7. Then, the first medium pipe box at the other end of the heat exchanger 3 is provided with a first medium inlet 5, and the second medium tube box 4 is provided with a second medium outlet 8. The casing heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com