Low-pressure large-flow overflow valve test system and test method thereof

A test system and high-flow technology, which is applied in the field of low-pressure and large-flow relief valve test systems, can solve problems such as the inability to meet the test requirements of low-pressure and large-flow relief valves, and achieve the effects of stable operation, accurate testing, and precise measurement and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

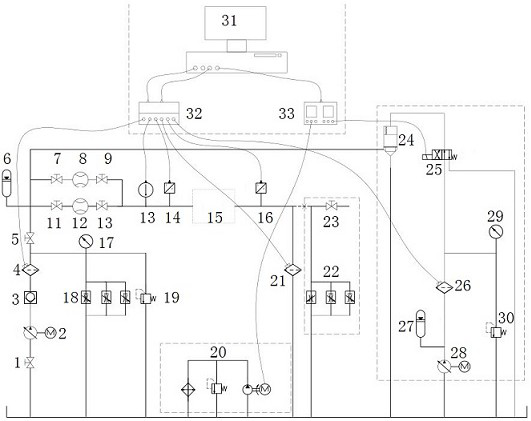

[0042] Embodiment 1, a kind of low-pressure high-flow relief valve test system, such as figure 1 As shown, it includes a circulation circuit and a signal acquisition control module connected to the low-pressure large-flow relief valve 15. The circulation circuit includes a main circuit oil pump unit, a test unit, an oil return unit, and a temperature control module 20 connected in sequence. The oil pump unit and the oil return unit are connected through an oil tank, and the temperature control module 20 is arranged in the oil tank. The signal acquisition control module includes a data acquisition device 32, a control device 33 and an industrial computer 31, and the three form a feedback control loop.

[0043] The main road pump oil unit includes a main road hydraulic pump driven by a main road variable frequency motor 2, which is provided with a triple flow valve 18, a main road pressure gauge 17, and a main road overflow valve 19 in parallel with the main road hydraulic pump....

Embodiment 2

[0049] Embodiment 2, a test method of a low-pressure and large-flow relief valve test system, including the pressure regulation range and pressure stability test of the low-pressure and large-flow relief valve 15, the internal leakage test of the low-pressure and large-flow relief valve 15, the low-pressure Pressure loss test of large flow relief valve 15.

[0050] 1.1 Test environment

[0051] Except for the environmental adaptability test, the rest of the tests were carried out under the conditions of laboratory ambient temperature, humidity and air pressure. The environmental adaptability test is carried out according to the corresponding part in GJB150A-2009 "Military Equipment Laboratory Environmental Test Methods".

[0052] 1.2 Test medium

[0053] Test medium: CD40 diesel engine oil (GB-11122-2006), 4450 aviation gear oil (GJB561-1988).

[0054] Test medium temperature: system oil temperature 55±5℃.

[0055] Pollution degree of the test medium: should not be higher ...

Embodiment 3

[0063] Embodiment 3, a test method of a low-pressure and high-flow relief valve test system, including the steady-state pressure-flow characteristic test of the low-pressure and high-flow relief valve 15, during the test, open the large-flow pipeline and close the small-flow pipeline, Adjust the main road relief valve 19 to full tightness, adjust the low pressure and large flow relief valve 15 to the upper limit of pressure regulation, control the speed of the main road variable frequency motor 2 through the control device 33, and monitor the flowmeter on the large flow channel at the same time, Make the flow rate of the test system a certain value in the range of 100-300 L / min, preferably 200 L / min, and carry out the following tests:

[0064] a. Adjust the main relief valve 19 so that the system pressure gradually drops to the closing rate pressure of the low pressure and large flow relief valve 15, close the large flow pipeline, open the small flow pipeline at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com