High-sensitivity microwave microfluidic sensor based on improved defected ground structure

A defect-based structure and high-sensitivity technology, applied in the microwave field, can solve problems such as cost increase, and achieve the effects of reducing dosage, improving sensitivity and accurate dielectric constant detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

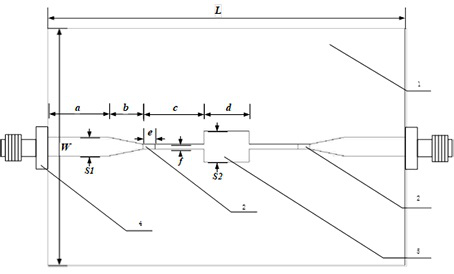

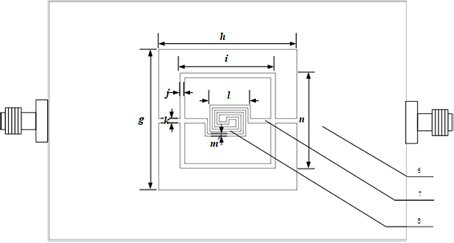

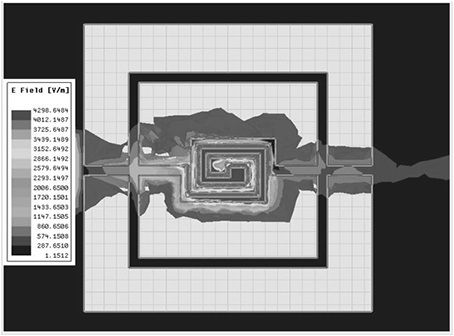

[0028] Example: Figure 1 to 2 As shown, based on the high-sensitivity microwave microfluidic sensor of the improved defective structure, a double-port device; a three-layer structure having a top layer, an intermediate layer, and a bottom layer; the SMA connecting head 4 located on the top layer is soldered in the microstrip line 5. On the side, the input and output terminal width of the microstrip wire is 1.63 mm, and the resistance welding portion is graded at 0.4 mm, and the microstrip line becomes a rectangle having a width of 2.6 mm in length of 3.8 mm. There are two gaps in the middle welding section of the microstrip line, soldered by 50 ohmic resistor components 2. The intermediate layer is Rogers 4350 dielectric plate 1. An improved DGS structure 7 is etched at the bottom layer. The spiral structure 8 is etched in the middle of the DGS structure to a square side length of 8 mm width of 0.4 mm, the spiral line width is 0.2 mm, and the helical line is connected to a square ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com