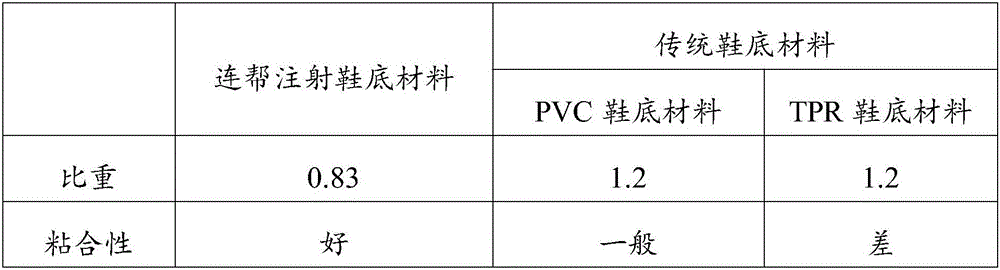

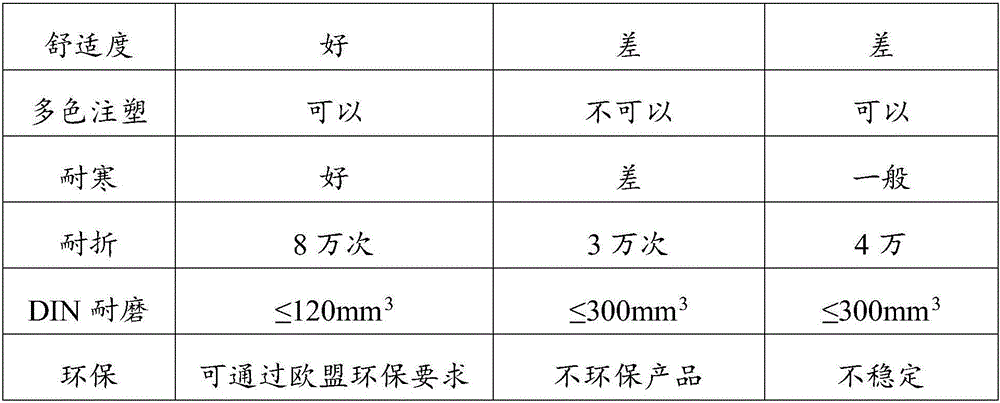

Continuous injection shoe sole material and processing method thereof, continuous injection shoe and processing method thereof

A technology for shoe sole materials and processing methods, which can be applied to footwear, other household appliances, household appliances, etc., and can solve the problems of complicated production processes, direct injection molding, and heavy quality of ordinary shoe materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The concrete processing method of the present embodiment is as follows:

[0058] (1) Preparation of oil-extended glue:

[0059] Styrene-Butadiene-Styrene Block Copolymer 80g naphthenic oil 50g mixing temperature 40℃ mixing time 3 hours

[0060] (2) Preparation of maleic anhydride modified propylene-based elastomer:

[0061] ExxonMobil 6102 50g Exxon Mobil 6202 50g maleic anhydride 2g dicumyl peroxide 0.5g Melting section temperature 200℃

[0062] (3) Preparation of hard material:

[0063] Oil-extended glue 130g polystyrene 20g K resin 25g Polyphenylene ether 20g Maleic anhydride modified propylene-based elastomer 5g Melting section temperature 180℃

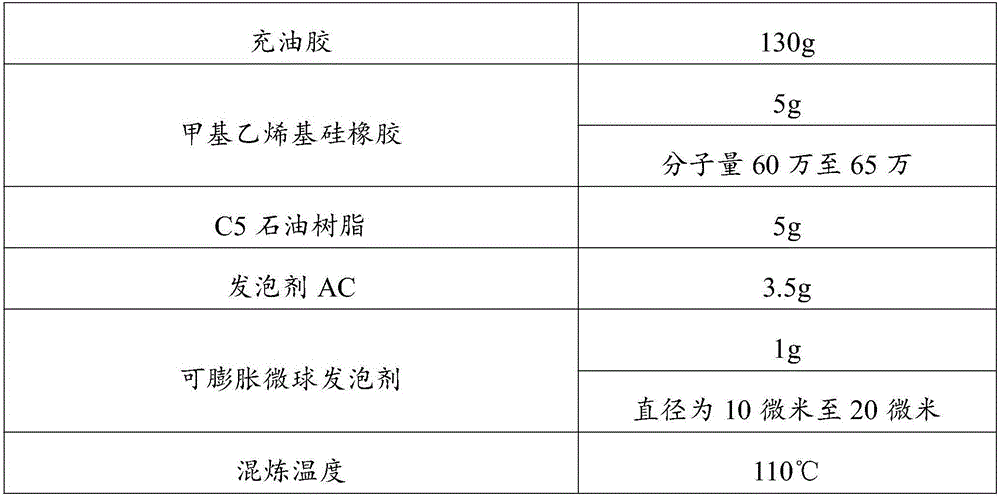

[0064] (4) Preparation of soft material:

[0065]

[0066] (5) The hard material and the soft material are mechanically mixed according to the weight ratio of 1:2 to obtain the upper injection sole mat...

Embodiment 2

[0069] The concrete processing method of the present embodiment is as follows:

[0070] (1) Preparation of oil-extended glue:

[0071] Styrene-Butadiene-Styrene Block Copolymer 50g white mineral oil 20g mixing temperature 80℃ mixing time 3 hours

[0072] (2) Preparation of maleic anhydride modified propylene-based elastomer:

[0073] ExxonMobil 6102 150g ExxonMobil VM3000 50g maleic anhydride 7g dicumyl peroxide 0.05g Melting section temperature 150℃

[0074] (3) Preparation of hard material:

[0075] Oil-extended glue 70g polystyrene 30g K resin 26g Polyphenylene ether 5g heavy calcium powder 10g Maleic anhydride modified propylene-based elastomer 20g Melting section temperature 280℃

[0076] (4) Preparation of soft material:

[0077]

[0078]

[0079] (5) The hard material and the soft material are mechanically mixed according to the weight rat...

Embodiment 3

[0082] The concrete processing method of the present embodiment is as follows:

[0083] (1) Preparation of oil-extended glue:

[0084] Styrene-Butadiene-Styrene Block Copolymer 75g naphthenic oil 45g mixing temperature 50℃ mixing time 2 hours

[0085] (2) Preparation of maleic anhydride modified propylene-based elastomer:

[0086] ExxonMobil 6102 60g Exxon Mobil 6202 40g ExxonMobil VM3000 10g maleic anhydride 3g dicumyl peroxide 0.1g Melting section temperature 190℃

[0087] (3) Preparation of hard material:

[0088] Oil-extended glue 120g polystyrene 22g K resin 24g Polyphenylene ether 15g heavy calcium powder 2g Maleic anhydride modified propylene-based elastomer 10g Melting section temperature 200℃

[0089] (4) Preparation of soft material:

[0090]

[0091] (5) The hard material and the soft material are mechanically mixed according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com