Health condition monitoring device for driving part of permanent magnet synchronous motor for monorail crane

A permanent magnet synchronous motor, health status technology, applied in the direction of measuring devices, measuring device casings, mechanical parts testing, etc., can solve the problem of real-time monitoring of the concentricity of the output shaft of the permanent magnet synchronous motor and the difficulty of detecting the casing of the permanent magnet synchronous motor Temperature changes, the inability to provide operators with evidence of friction, etc., to improve monitoring efficiency, reduce network congestion, and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

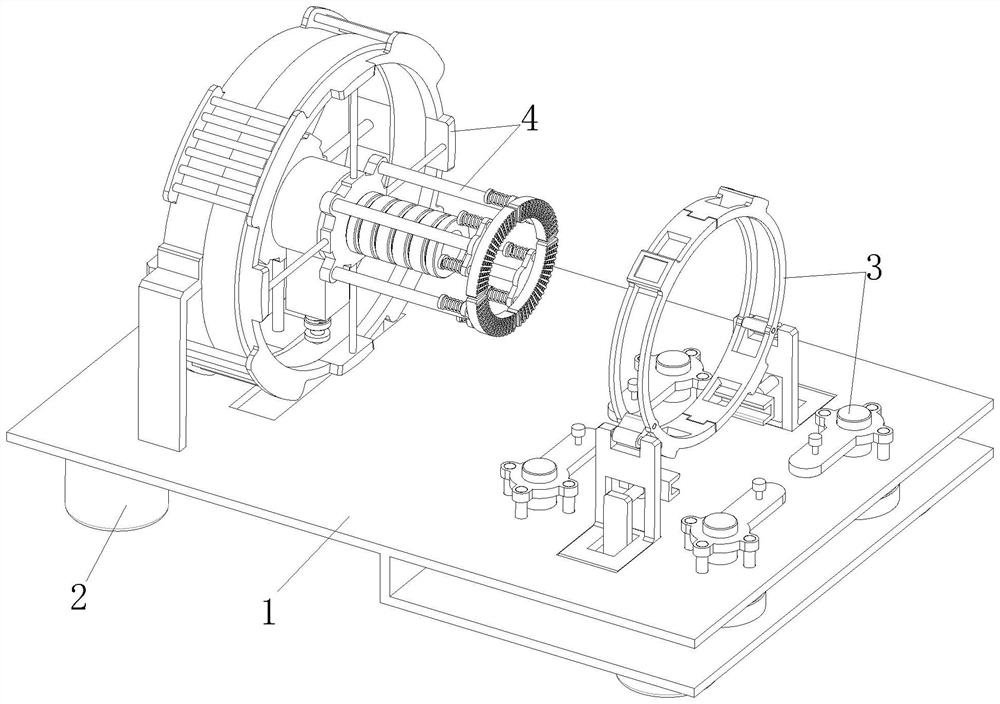

[0043] refer to figure 1 , a permanent magnet synchronous motor drive unit health monitoring device for monorail cranes according to the present invention, comprising an underframe 1, a support foot 2, a positioning mechanism 3 and a monitoring mechanism 4, and the corners around the lower end of the underframe 1 are all Support feet 2 are installed, a positioning mechanism 3 is installed on the rear upper end of the underframe 1 , and a monitoring mechanism 4 is installed on the front upper end of the underframe 1 .

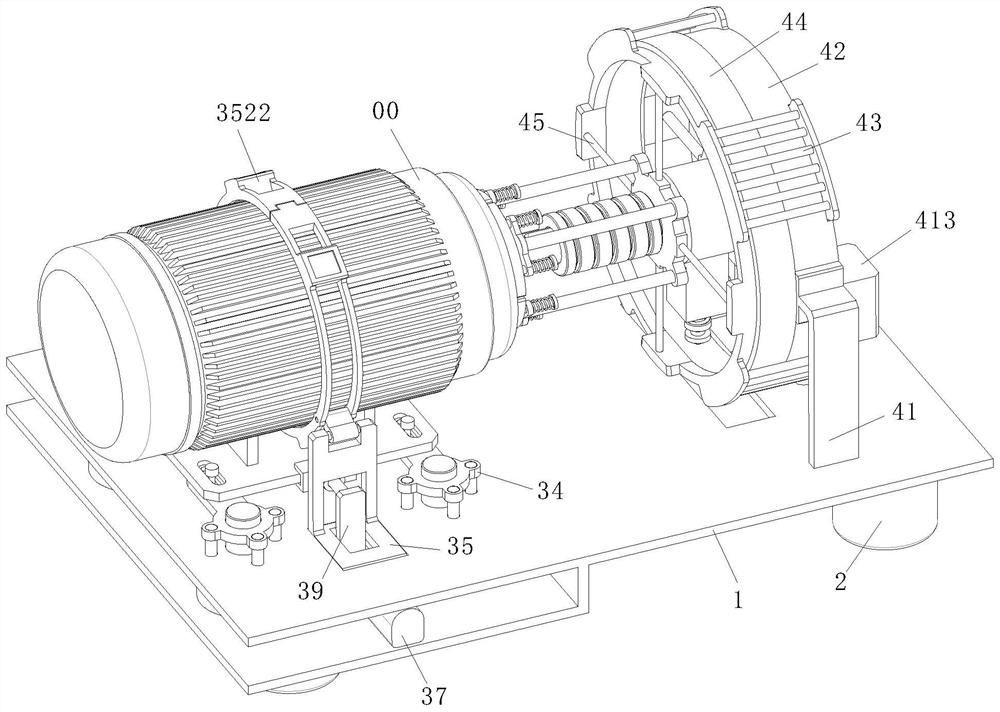

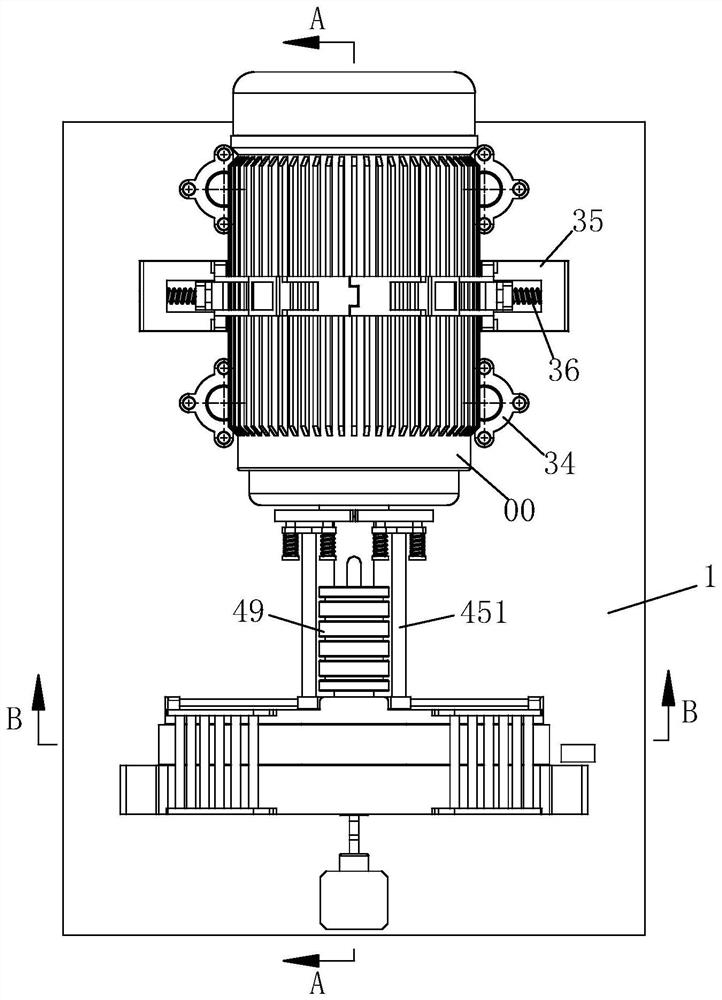

[0044] refer to figure 2 , image 3 , Figure 7 with Figure 9 The positioning mechanism 3 includes a positioning seat 31, a brake lever 32, a positioning screw rod 33, a positioning plate 34, a convex frame 35, a two-way screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com