Motor leading-out wire with anti-static and anti-dislocation structure

An anti-static, lead-out technology, applied in circuits, insulated cables, electrical components, etc., can solve problems such as motor burnout, motor coil burnout, and single function design of motor lead-out wires, to avoid current disturbance and to achieve high fire-resistant insulation performance , to avoid the effect of secondary accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

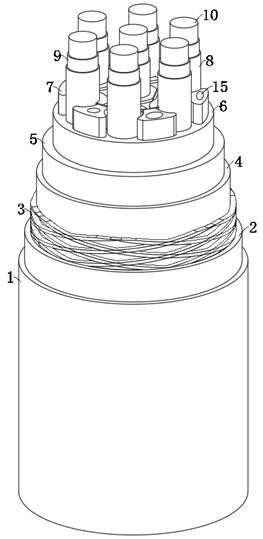

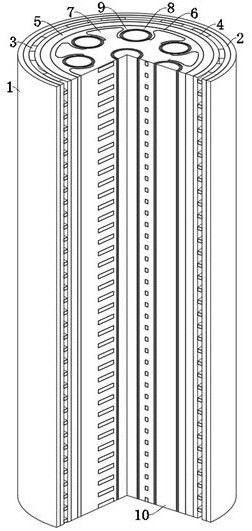

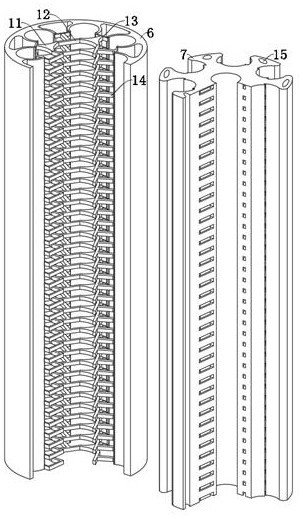

[0034] Embodiment one, with reference to Figure 1-5 : A motor lead wire with anti-static discharge dislocation structure, comprising:

[0035] Insulating outer sheath 1;

[0036] A plurality of copper conductors 10 are arranged in the insulating outer sheath 1;

[0037] The supporting mechanism is set in the insulating outer sheath 1 and is used for the main body support of the lead-out wires. The supporting mechanism includes an outer bracket 6 and multiple sets of positioning components. The outer bracket 6 is installed in the insulating outer sheath 1. Multiple sets of positioning components The components are evenly arranged inside the outer bracket 6 near the center, and each set of positioning components is provided with three positioning frames 11, the three positioning frames 11 are evenly distributed, and a plurality of copper conductors 10 are clamped and arranged in the outer bracket 6 respectively; and

[0038] The anti-static mechanism is located in the outer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com