Comprehensive support hanger system and construction method thereof

A construction method and technology for supporting and hanging brackets are applied in the field of brackets, which can solve the problems of narrow available space, difficult construction, and large installation workload, and achieve the effects of reducing space requirements, reducing drilling difficulty, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

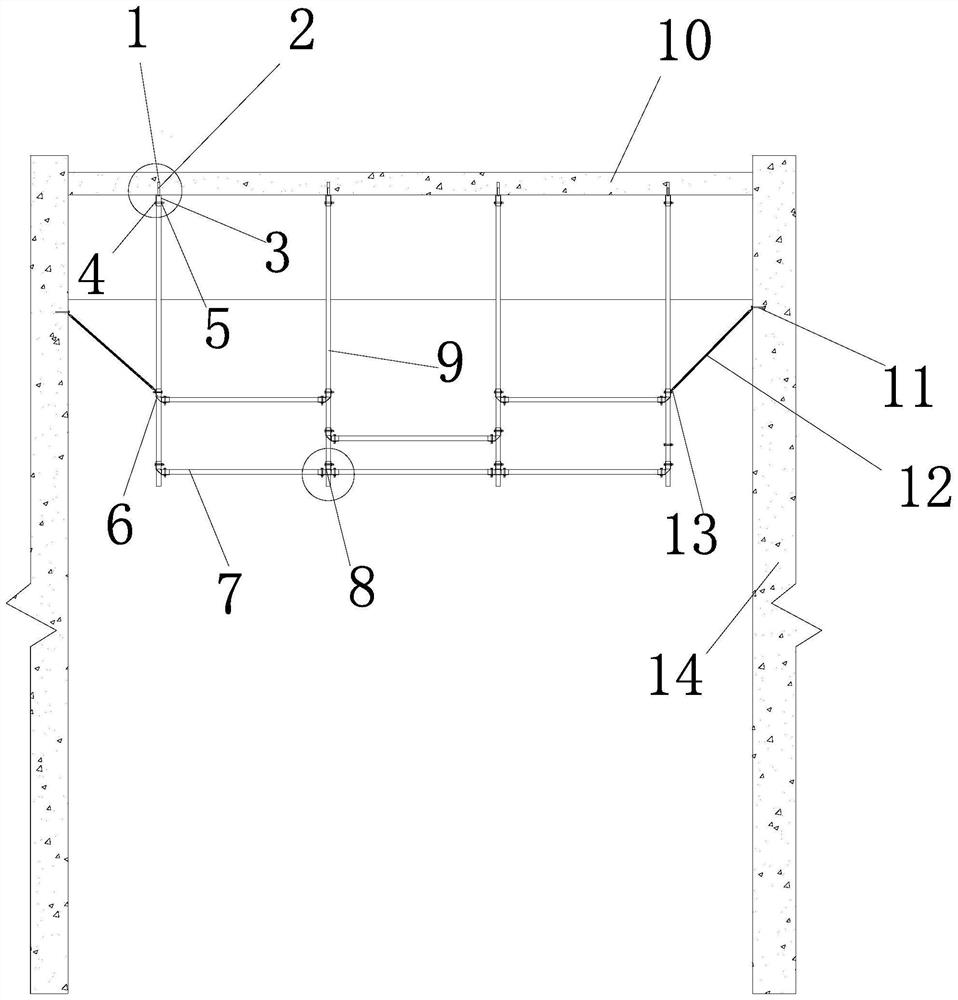

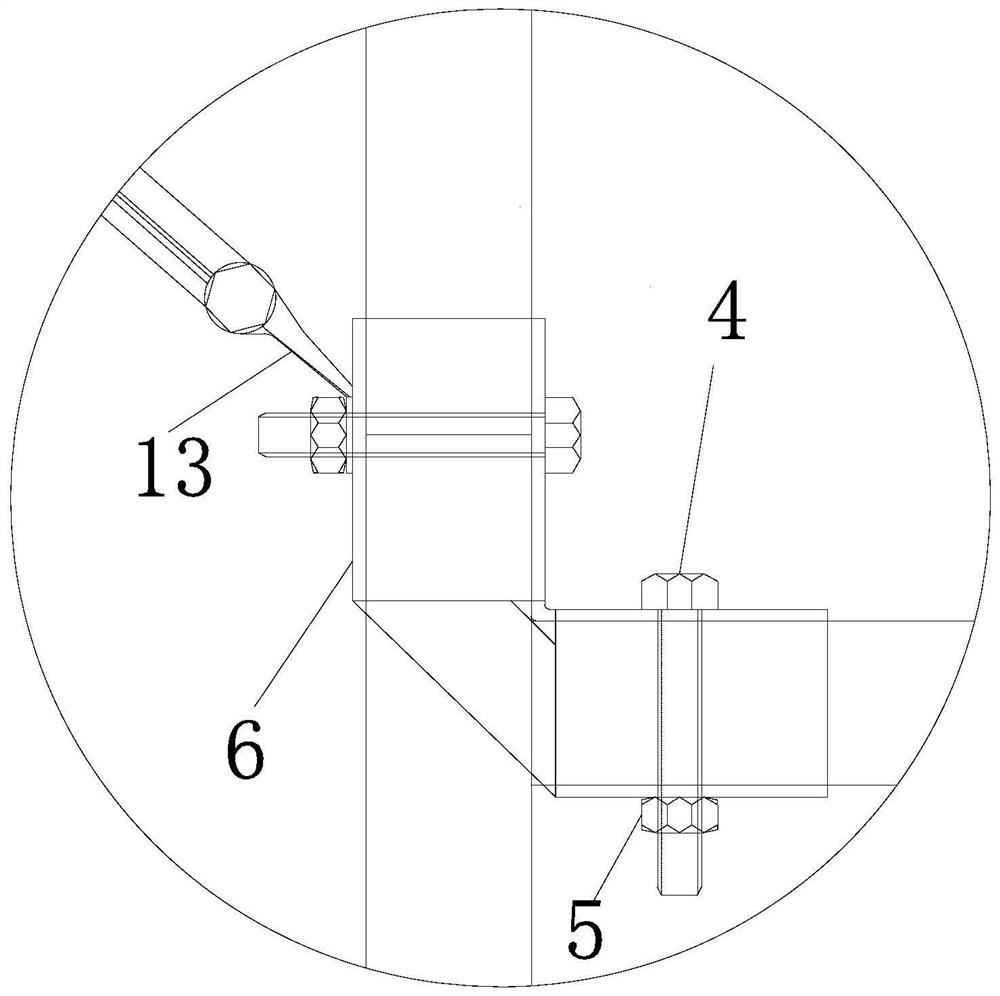

[0043] Such as Figure 10 As shown, the construction method of this integrated bracket system includes the following steps:

[0044] S000, preset the preset bubble strip 2 is embedded in the floor 10, and the floor 10 is poured;

[0045] In this step, when the floor is applied, the pre-buried foam strip 2 is embedded in the floor 10 according to the pre-designed point position, and then the floor is poured again, so that the pre-buried foam strip 2 is fixed to the floor 10 . The wall 14 is provided on both sides of the floor 10.

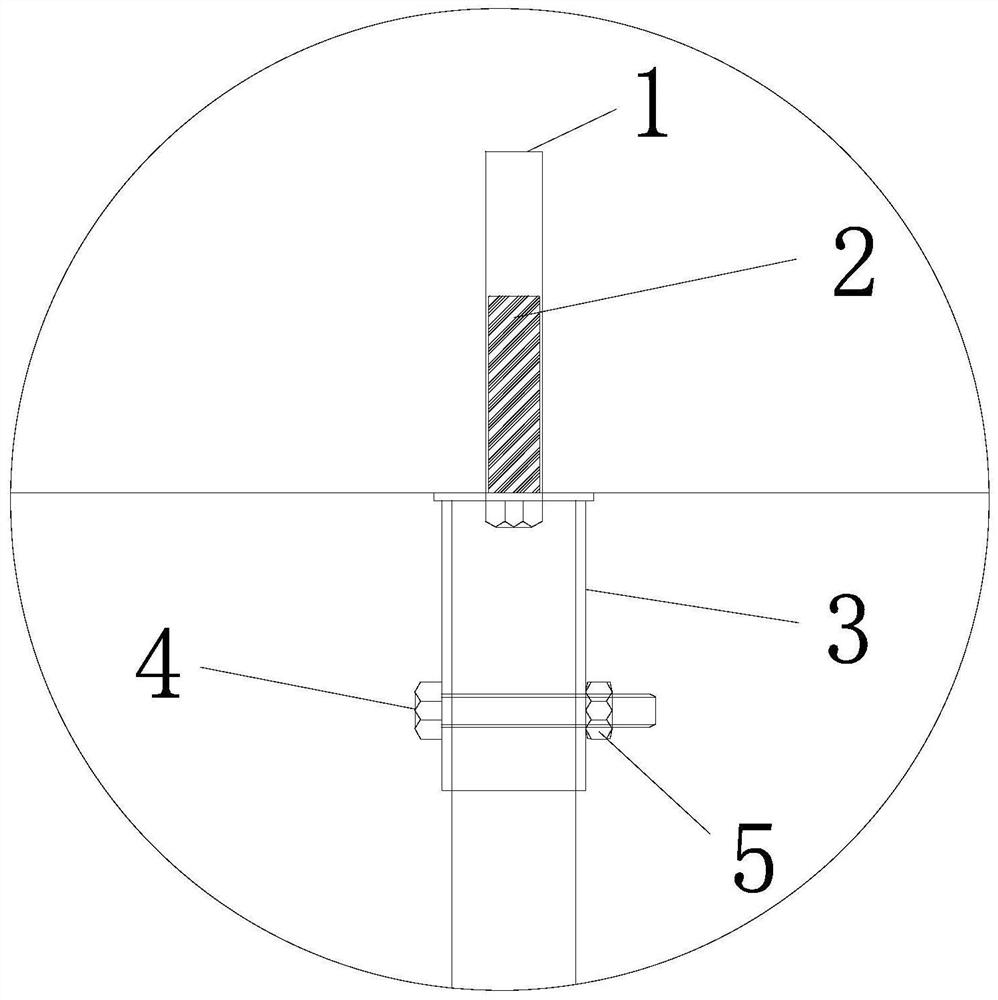

[0046]S100, after the landing 10 reaches the design intensity, the bore is drilled in each pre-buried foam strip 2 to implant the anchor implantation 1;

[0047] In this step, the embedded foam strip 2 is first positioned, and the second is to facilitate the implantation of anchor 1 to implant into the position where the embedded foam strip is located, reducing the construction difficulty.

[0048] S200, securing the bolt sleeve 3 to the floor 10 by impla...

Embodiment 2

[0061] The integrated bracket hanger system is made using the above-mentioned integrated bracket system construction method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com