Method for assembling asymmetric supercapacitor based on PVA-PMA-SA-TA self-healing gel

A PVA-PMA-SA-TA, supercapacitor technology, applied in the direction of electrolytic capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of small voltage window of supercapacitors and easy deformation of supercapacitors, and achieve high cost performance and high Effect of energy density and power density, wide operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

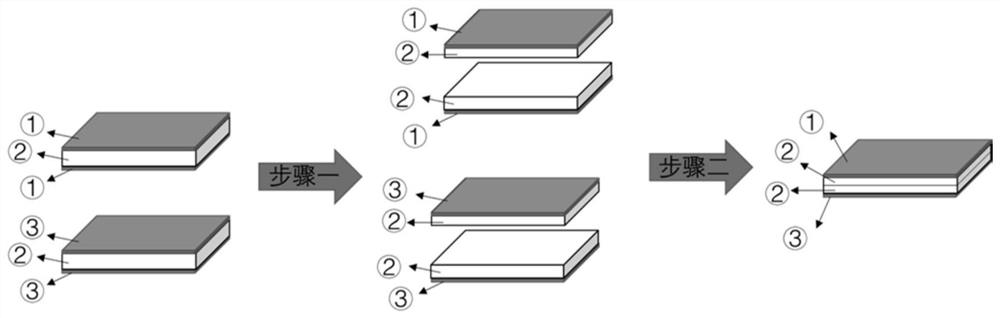

Image

Examples

specific Embodiment approach 1

[0032] Dissolve 1 g of polyvinyl alcohol PVA into 10 mL of deionized water, and stir at 95°C for 2 hours, the solution becomes clear and transparent. Dissolve 0.15 g of sodium alginate SA and 1.5 g of methacrylic acid MA into the PVA solution and stir for 3 hours. Slowly add 1.5g of ammonium persulfate APS into the solution, and put the solution at 60°C for 2 hours to make methacrylic acid MA polymerized into polymethacrylic acid PMA; after the reaction, take it out, cool it naturally, and use a freeze dryer Freeze dried. Soak the freeze-dried gel in 5 wt.% tannic acid for 24 hours at room temperature. The PVA-PMA-SA-TA hydrogel can be obtained.

[0033] 0.16g MoS 2and 0.275mL of pyrrole Py were added to 10mL of 0.5mol / L sulfuric acid solution, and dissolved by ultrasound for 30 minutes. Cut the PVA-PMA-SA-TA hydrogel into a cube with a length, width, and height of 2 cm, 2 cm, and 0.5 cm, put it into the obtained solution, and let it stand for 20 minutes. Dissolve 0.912g ...

specific Embodiment approach 2

[0037] Dissolve 1 g of polyvinyl alcohol PVA into 10 mL of deionized water, and stir at 95°C for 2 hours, the solution becomes clear and transparent. Dissolve 0.2g sodium alginate SA and 2g methacrylic acid MA into the PVA solution and stir for 3 hours. Slowly add 2g of ammonium persulfate APS into the solution, and place the solution at 60°C for 2 hours to make methacrylic acid MA polymerized into polymethacrylic acid PMA; take it out after the reaction, cool naturally, and freeze it with a freeze dryer dry. Soak the freeze-dried gel in 10 wt.% tannic acid for 36 hours at room temperature. The PVA-PMA-SA-TA hydrogel can be obtained.

[0038] 0.32g MoS 2 and 0.275mL of pyrrole Py were added to 10mL of 0.5mol / L sulfuric acid solution, and dissolved by ultrasound for 30 minutes. Cut the PVA-PMA-SA-TA hydrogel into a cube with a length, width, and height of 6 cm, 6 cm, and 0.5 cm, put it into the obtained solution, and let it stand for 20 minutes. Dissolve 0.912g of ammonium...

specific Embodiment approach 3

[0042] Dissolve 1 g of polyvinyl alcohol PVA into 10 mL of deionized water, and stir at 95°C for 2 hours, the solution becomes clear and transparent. Dissolve 0.25g sodium alginate SA and 2.5g methacrylic acid MA into the PVA solution and stir for 3 hours. Slowly add 2.5g of ammonium persulfate APS into the solution, put the solution at 60°C for 2 hours to make methacrylic acid MA polymerize into polymethacrylic acid PMA; take it out after reaction, cool naturally, and use a freeze dryer Freeze dried. Soak the freeze-dried gel in 15wt.% tannic acid for 48 hours at room temperature. The PVA-PMA-SA-TA hydrogel can be obtained.

[0043] 0.64g MoS 2 and 0.275mL of pyrrole Py were added to 10mL of 0.5mol / L sulfuric acid solution, and dissolved by ultrasound for 30 minutes. Cut the PVA-PMA-SA-TA hydrogel into a cube with a length, width, and height of 10 cm, 10 cm, and 0.5 cm, put it into the obtained solution, and let it stand for 20 minutes. Dissolve 0.912g of ammonium persul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com