Beam splitting amplification quasi-continuous fiber laser

A fiber laser, quasi-continuous technology, applied in the direction of lasers, laser devices, laser components, etc., can solve the problems of difficult preparation and poor stability, and achieve the effect of optimizing beam quality, reducing capacitance characteristics, and maintaining beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

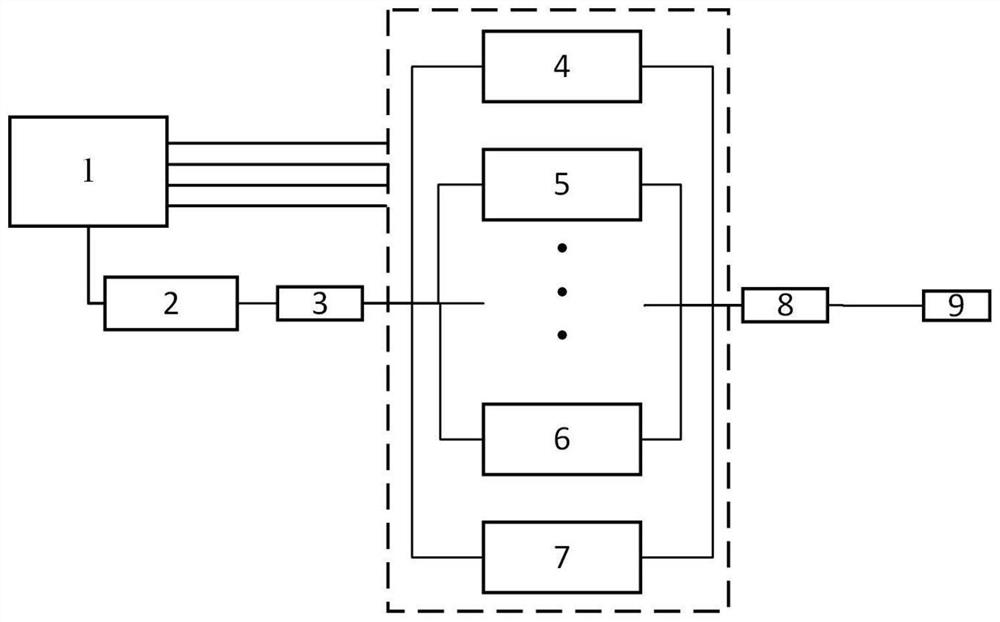

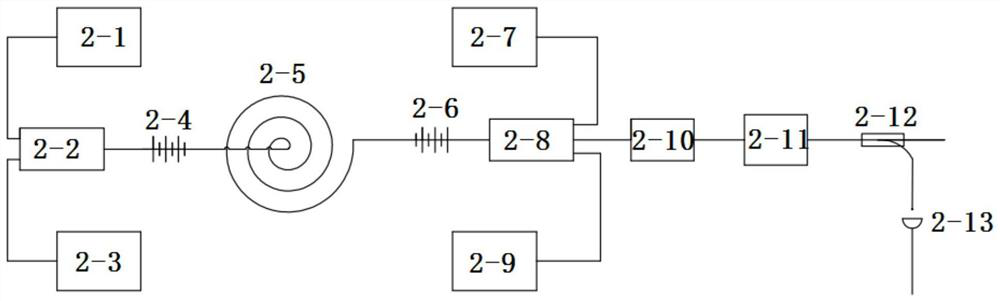

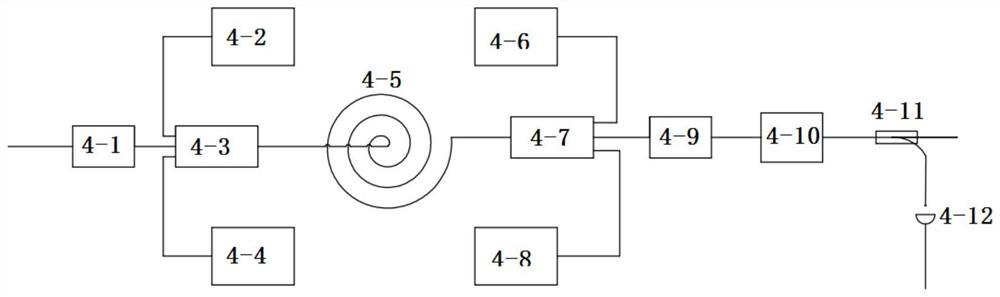

[0025] Such as figure 1 As shown, a beam-splitting and amplifying quasi-CW fiber laser includes a centralized control unit 1 , a seed laser 2 , a beam splitter 3 , multiple optical path amplification stages, a beam combiner 8 and a laser output structure 9 .

[0026] The centralized control unit 1 is composed of FPGA and additional circuits, and its functions include a multi-channel pump laser pulse drive circuit 1-1, a power monitoring and control circuit 1-2, and a human-computer interaction interface 1-3, wherein: the multi-channel pump laser The laser pulse drive circuit 1-1 is respectively connected with the seed laser 2 and the pump lasers of multiple optical path amplification stages; the power monitoring and control circuit 1-2 is connected with the seed laser 2 and the photodetector control circuit of multiple optical path amplification stages The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com