Pressing film without rubber mat as well as preparation method and application of pressing film

A non-adhesive, film-pressing technology, which is applied in the field of plastic films, can solve the problems of hot-pressing deformation of films and pure cotton fabrics, and achieve good bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A pressure film without a rubber pad, consisting of three layers A, B, and C from top to bottom, wherein the A layer is composed of component A: 75 parts of Mitsui resin NF528, 25 parts of polyethylene, 5 parts of low-density polyethylene 2 parts, 2 parts of fluorinated polyethylene, 1 part of silicon dioxide;

[0024] The component B is composed of the following parts by weight: 75 parts of polypropylene, 25 parts of polyolefin elastomer 8880;

[0025] The component C is composed of the following components in parts by weight: 75 parts of Mitsui resin NF528, 25 parts of polyethylene, 5 parts of low-density polyethylene, 2 parts of fluorinated polyethylene, and 1 part of silicon dioxide;

[0026] The mass ratio of the components A, B, and C is 6:16:6;

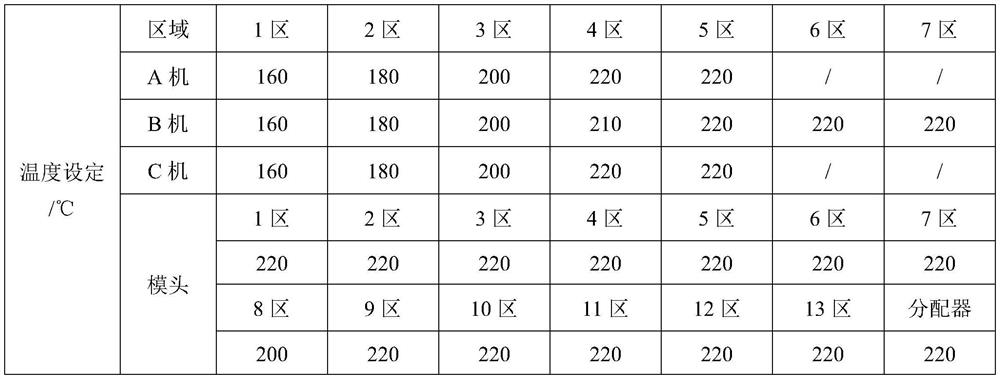

[0027] The components A, B, and C are respectively melt-extruded by screw extruders (components A, B, and C correspond to A, B, and C in turn), and are merged together by the distributor after filtering the filter net ...

Embodiment 2

[0029] A pressure film without a rubber pad, consisting of three layers A, B, and C from top to bottom, wherein the A layer is composed of component A: 70 parts of Mitsui resin NF528, 20 parts of polyethylene, 3 parts of low-density polyethylene 1 part, 1 part of fluorinated polyethylene, 0.5 part of silicon dioxide;

[0030] The component B is composed of the following parts by weight: 70 parts of polypropylene, 20 parts of polyolefin elastomer 8880;

[0031] The component C is composed of the following components in parts by weight: 70 parts of Mitsui resin NF528, 20 parts of polyethylene, 3 parts of low-density polyethylene, 1 part of fluorinated polyethylene, and 0.5 parts of silicon dioxide;

[0032] The mass ratio of the components A, B, and C is 6:16:6;

[0033] The preparation method is the same as in Example 1.

Embodiment 3

[0035] A pressure film without a rubber pad, consisting of three layers A, B, and C from top to bottom, wherein the A layer is composed of component A: 80 parts of Mitsui resin NF528, 30 parts of polyethylene, 6 parts of low-density polyethylene 3 parts, 3 parts of fluorinated polyethylene, 1 part of silicon dioxide;

[0036] The component B is composed of the following parts by weight: 80 parts of polypropylene, 30 parts of polyolefin elastomer 8880;

[0037] The component C is composed of the following components in parts by weight: 80 parts of Mitsui resin NF528, 30 parts of polyethylene, 6 parts of low-density polyethylene, 3 parts of fluorinated polyethylene, and 1 part of silicon dioxide;

[0038] The mass ratio of the components A, B, and C is 6:16:6;

[0039] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com