Combination recovery rocket overall structure based on general core level

A combination and rocket technology, applied in the aerospace field, to optimize the force transmission path, improve the connection reliability, and achieve the effect of propellant management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

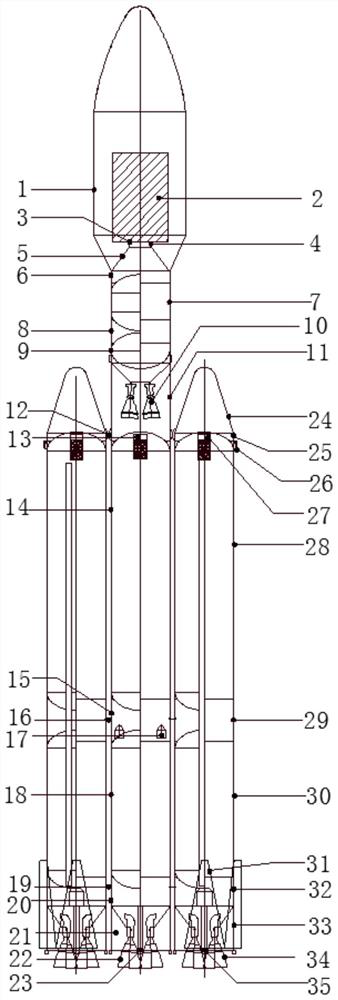

[0030] Such as figure 1 As shown, the present invention provides a general configuration of recovery rocket based on a general-purpose core stage assembly, including the following components:

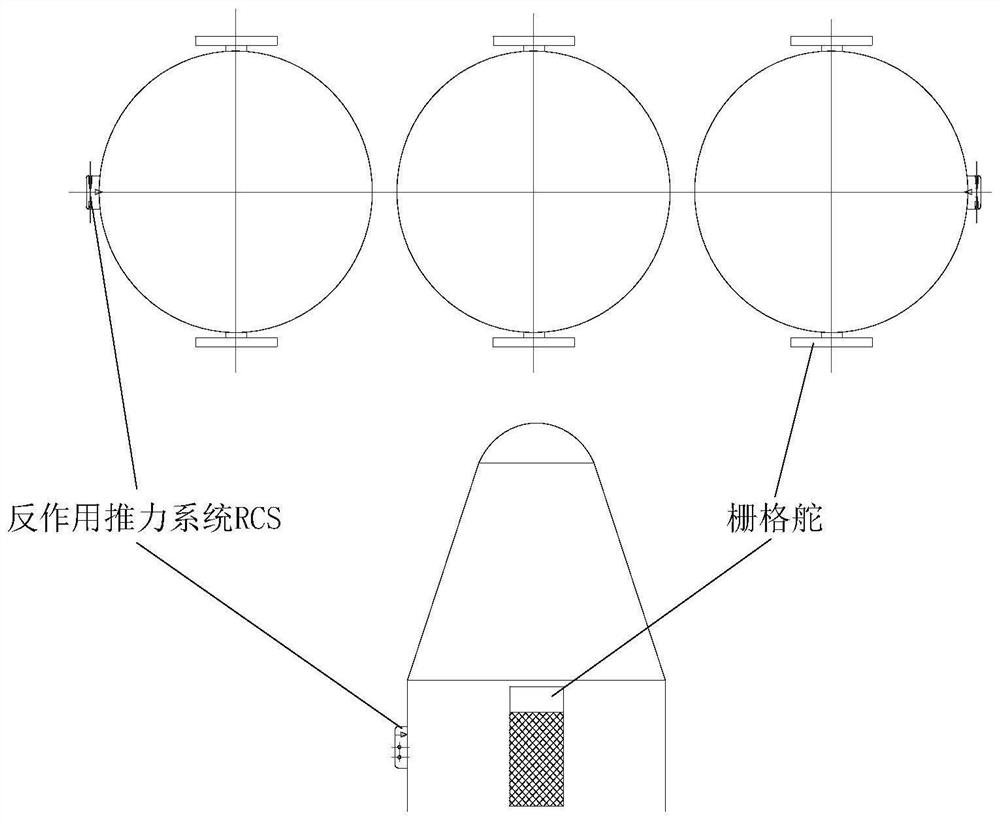

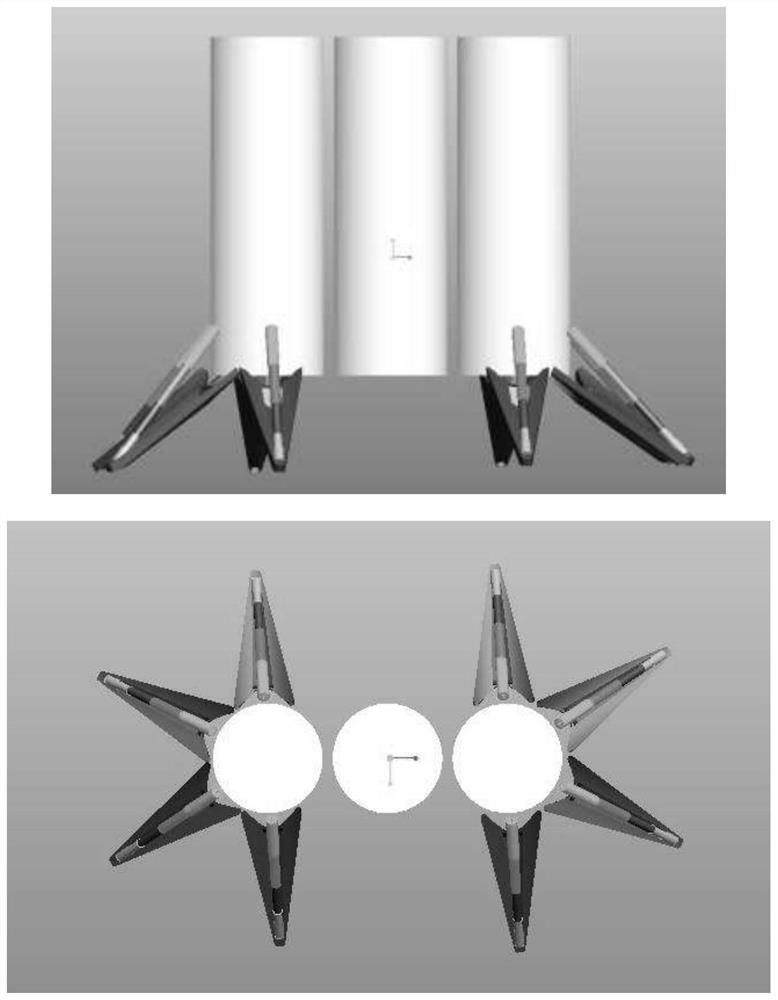

[0031] Core level one, including two level one liquid oxygen kerosene engines 22, one level heat shield 23, one level tail section 21, one level rear transition section 20, one level kerosene tank 18, one level inter-tank section 15, one level Liquid oxygen tank 14, grid rudder 13, first- and second-stage sections 11; among them, two first-stage liquid oxygen kerosene engines 22 are installed at the bottom of the first-stage tail section 21, work in a two-way swing mode, and have take-off and return deceleration 3 ignitions in the first an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com